類別

特色產品

Color Coated Galvanized Steel Coil PPGI

簡短的介紹:

PPGI (Pre-Painted Galvanized Iron) Steel Coils combine hot-dip or electro-galvanized bases with UV-resistant polymer coatings, offering 5–15-year lifespans in harsh environments. Designed for roofing, appliances, and automotive parts, PPGI achieves ASTM B117 500h salt spray resistance and 85% solar reflectance. Available in RAL 9000–RAL 9023 hues, these coils feature PE/SMP/HDP/PVDF coatings (10–30µm) with gloss levels up to 95 GU for architectural and industrial use.

Color Coated Galvanized Steel Coil PPGI Product Overview

PPGI (Pre-Painted Galvanized Iron) Steel Coils combine hot-dip or electro-galvanized bases with UV-resistant polymer coatings, offering 5–15-year lifespans in harsh environments. Designed for roofing, appliances, and automotive parts, PPGI achieves ASTM B117 500h salt spray resistance and 85% solar reflectance. Available in RAL 9000–RAL 9023 hues, these coils feature PE/SMP/HDP/PVDF coatings (10–30µm) with gloss levels up to 95 GU for architectural and industrial use.

Technical Specifications

1. Base Material & Dimensions

| Parameter | Hot-Dip PPGI | Electro-Galvanized PPGI |

|---|---|---|

| Zinc Coating | 275 g/m² (Z275) | 20–90 g/m² (ZE20–ZE90) |

| Thickness | 0.13–0.8 mm (±0.02mm tolerance) | 0.13–0.6 mm (±0.02mm tolerance) |

| Width | 600–1,250 mm (slit-to-size) | 600–1,250 mm |

| Coil Weight | 3–12 tons (ID: 508/610 mm) | 2–8 tons |

2. Coating System

| Layer | Coating Type | Thickness | Key Performance |

|---|---|---|---|

| Topcoat | PVDF/HDP/SMP/PE | 15–30 µm | 15+ years color retention (ISO 4892) |

| Primer | Epoxy/Polyester | 5–15 µm | Adhesion: Class 0 (ISO 2409 cross-cut) |

| Backing Coat | Acrylic/Polyurethane | 5–10 µm | Anti-fingerprint, scratch resistance |

Surface Treatments & Performance

1. Laminated Film (30–50µm)

- Features: Fire resistance (Class A ASTM E84), anti-graffiti, fingerprint-proof.

- Applications: High-traffic areas (elevators, subway panels).

2. Embossed Finish

- Patterns: Stucco, rhombus, wood grain (customizable).

- Benefits: 3D texture hides scratches, improves slip resistance (Rz ≥8µm).

3. Coating Comparison

| Type | UV Resistance | Cost | Best For |

|---|---|---|---|

| PVDF | 20+ years | High | Coastal roofs, façades |

| HDP | 15 years | Moderate | Solar farms, HVAC ducts |

| SMP | 10 years | Low | Indoor partitions, furniture |

| PE | 5–7 years | Budget | Temporary structures, packaging |

Performance Advantages

- Corrosion Resistance: Z275 hot-dip base outperforms electro-galvanized by 3x in humidity.

- Formability: 0.4T bend radius (0.3mm thickness) for roll-forming/press-braking.

- Thermal Efficiency: Reflective coatings reduce rooftop temps by 10–15°C (ASHRAE 90.1).

- Weight Savings: 30% lighter than aluminum panels (2.7 g/cm³ density).

- Cost-Effective: 40% cheaper than PPGL with comparable durability in mild climates.

Industry Applications

| Sector | Use Case | Recommended Coating |

|---|---|---|

| Construction | Warehouse roofs, cladding | PVDF (RAL 9006) |

| Automotive | Truck trailer interiors | SMP (RAL 7035) |

| Appliances | Washing machine panels | HDP (RAL 1015) |

| Furniture | Office cabinets, lockers | PE (RAL 5021) |

Certifications & Standards

- Quality: ISO 9001, ASTM A653 (Galvanized)

- Safety: EN 13501-1 (Fire Class B-s1, d0)

- Sustainability: 25% recycled content, RoHS-compliant coatings

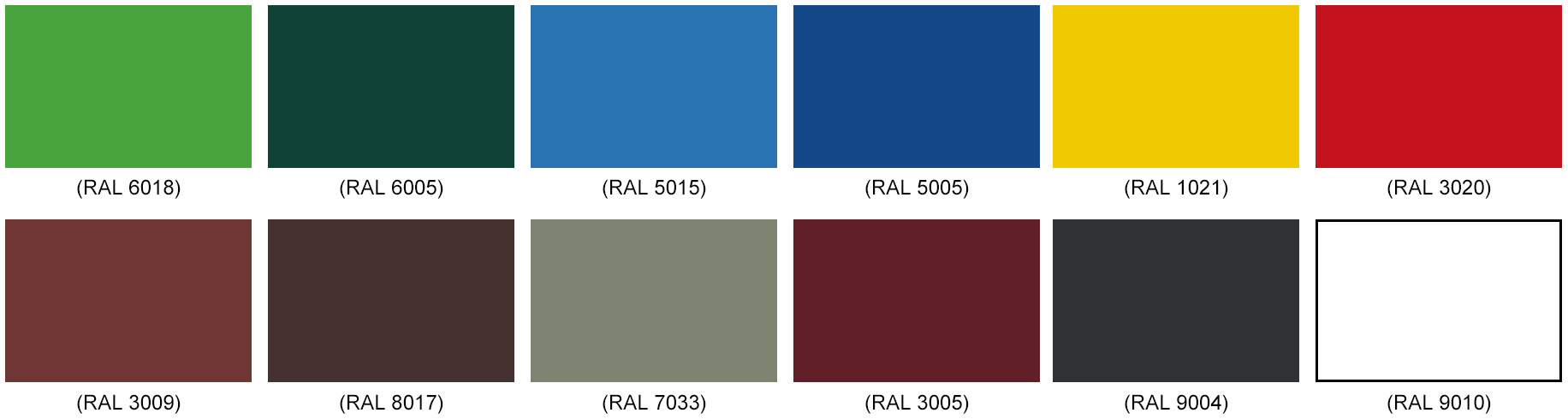

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

Packing And Delivery

留言