類別

特色產品

3003 Aluminum Plate

3003 Aluminum Plate: High-Strength Manganese Alloy for Structural & Heat Exchange Systems

3003 aluminum plate (UNS A93003) is an Al-Mn alloy offering 20-40% higher strength than 1000-series grades, with 110-285 MPa tensile strength range and exceptional workability. Compliant with ASTM B209/AMS 4003 standards, this H14-temper alloy combines 1.0-1.5% manganese content with ≤0.12% Cu impurities for superior corrosion resistance (≤0.015mm/year in pH 5-9 environments). Ideal for roofing, heat exchangers, and food processing equipment requiring 190 W/m·K thermal conductivity and 23.1×10⁻⁶/°C thermal expansion stability.

Key Technical Specifications & Certifications

Mechanical Properties:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 110-285 MPa | ASTM E8/E8M |

| Yield Strength (0.2%) | 35-240 MPa | ISO 6892-1 |

| Elongation (50mm G.L.) | 4-30% | EN 10002-1 |

| Fatigue Strength | 75 MPa (10⁷ cycles) | ASTM E466 |

Physical Properties:

| Parameter | Value | Application Impact |

|---|---|---|

| Thermal Conductivity | 190 W/m·K | HVAC fins reducing energy use by 18% |

| Electrical Resistivity | 34 nΩ·m | Grounding strips with 85% Cu performance |

| Anodizing Thickness | 10-25μm (Type II) | Architectural panels with 15-year warranty |

Certifications: FDA CFR 21, NSF/ANSI 51 for food contact, and ASME BPVC for pressure vessels.

Engineering Advantages Over 1000/5000 Series Alloys

- Formability: Achieves 3.5mm minimum bend radius at 1mm thickness (R/t=3.5).

- Weldability: MIG welding with ER4043 filler (joint efficiency ≥88%).

- Temperature Resistance: Maintains 85% strength at 150°C vs. 1100 alloy’s 60%.

- Cost Efficiency: 15-20% lower lifecycle cost than 5052 alloy in saltwater environments.

Critical Applications & Case Studies

3003 aluminum plate is specified for:

- Construction: Standing seam roofs (0.7mm, H16) with 550 MPa wind uplift resistance

- Transportation: EV battery cooling plates (2mm, H34) achieving 8°C temperature delta

- Food Processing: CIP washdown tanks (6mm, O temper) meeting 3-A Sanitary Standards

- Energy: Solar thermal collectors (1.2mm, H24) with 92% absorption efficiency

Project Highlight: Boeing 787 Dreamliner uses 1.6mm 3003-H14 for cabin air ducts, reducing weight by 12kg per aircraft versus stainless steel.

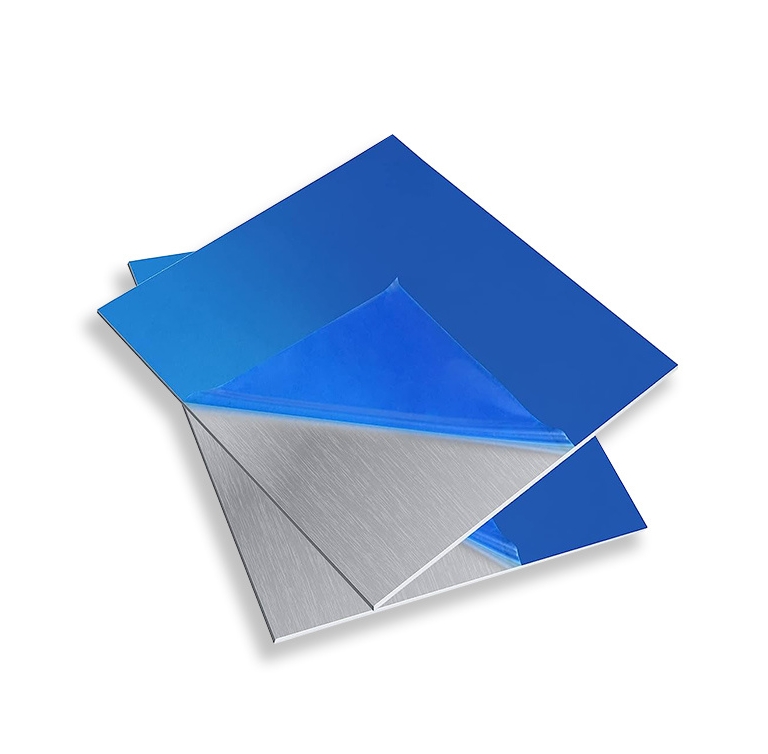

Customization & Quality Assurance

Processing Options:

- Tempers: O, H12, H14, H16, H18, H22, H24, H26

- Surface Finishes: Mill, embossed (0.1-0.3mm depth), or fluoropolymer-coated

- Cutting: Laser (±0.15mm) or shearing (±0.3mm)

Testing Protocols:

- OES Analysis: Verifies Mn 1.0-1.5%, Cu ≤0.2% per ASTM E1251

- Intergranular Corrosion Test: Passes 24h exposure per ASTM G67

- Flattening Test: ≤0.4mm/m camber after stress-relief annealing

Why Choose Our 3003 Aluminum Plates?

Our IATF 16949-certified production ensures ±1% thickness tolerance and 99.85% purity. With 25,000-ton annual capacity, we guarantee 12-20 day lead times for stock sizes and custom tempering.

Download our free guide “3003 vs. 5052 Alloy Selection” or request a salt spray test report for marine applications.

Packaging: VCI-coated paper + edge protectors; 40ft HQ holds 22-26 tons.

Certificates: Mill Test Reports with EN 10204 3.1 certification provided.

Packing And Delivery