The Importance of PPGL Steel Coils in Modern Construction

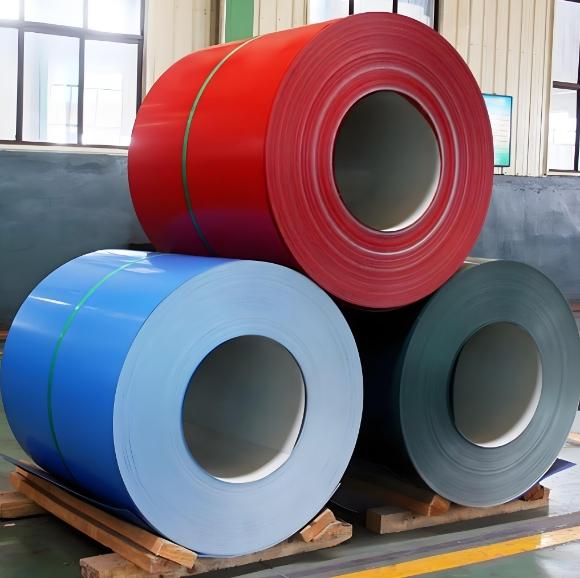

In the realm of construction and manufacturing, PPGL steel coils have emerged as a cornerstone material due to their exceptional durability, corrosion resistance, and aesthetic versatility. Pre-painted galvalume steel coils, commonly referred to as PPGL, combine the strength of steel with the protective benefits of aluminum-zinc alloy coatings and pre-painted finishes. This fusion results in a product that not only withstands harsh environmental conditions but also offers design flexibility for various applications.

However, not all PPGL steel coils are created equal. Understanding the nuances that contribute to their durability is crucial for architects, builders, and manufacturers aiming for long-lasting and cost-effective solutions. This article delves into five industry secrets that enhance the durability of PPGL steel coils, providing insights backed by real-world data and expert experiences.

Secret 1: Optimal Coating Composition Enhances Longevity

The durability of PPGL steel coils significantly depends on the composition of their metallic coatings. Typically, these coils feature a galvalume coating composed of approximately 55% aluminum, 43.5% zinc, 和 1.5% silicon. This specific blend offers superior corrosion resistance compared to traditional galvanized coatings.

According to industry data, PPGL steel coils with this aluminum-zinc composition can last up to three times longer than their galvanized counterparts, especially in coastal and industrial environments. The aluminum component provides a barrier against corrosion, while zinc offers sacrificial protection, ensuring the underlying steel remains intact over extended periods.

Secret 2: High-Quality Paint Systems Provide Additional Protection

Beyond metallic coatings, the pre-painted layer on PPGL steel coils plays a pivotal role in their durability. High-quality paint systems, such as Polyvinylidene Fluoride (PVDF) and Silicone Modified Polyester (SMP), offer enhanced UV resistance, color retention, and protection against environmental pollutants.

For instance, PVDF coatings can withstand UV exposure and maintain color integrity for over 20 years, making them ideal for structures exposed to intense sunlight. SMP coatings, while slightly less durable than PVDF, still offer excellent resistance to weathering and are often more cost-effective.

Secret 3: Proper Substrate Selection Ensures Structural Integrity

The base steel, or substrate, used in PPGL coils must possess adequate strength and formability to endure various fabrication processes and service conditions. Commonly used substrates include DX51D, DX52D, and DX53D grades, each offering different mechanical properties.

Selecting the appropriate substrate grade ensures that the final product can withstand mechanical stresses without compromising its structural integrity. For applications requiring deep drawing or complex forming, higher-grade substrates like DX53D are preferred due to their superior elongation properties.

Secret 4: Advanced Manufacturing Processes Enhance Performance

The manufacturing process of PPGL steel coils involves several critical stages, including cleaning, coating, painting, and curing. Advanced techniques, such as continuous hot-dip coating and precise temperature control during curing, ensure uniform coating thickness and adhesion.

Implementing stringent quality control measures throughout the production process minimizes defects and enhances the overall performance of the coils. For example, maintaining consistent line speeds and coating weights ensures that each coil meets the desired specifications, leading to improved durability in end-use applications.

Secret 5: Regular Maintenance and Inspection Prolong Service Life

Even the most durable PPGL steel coils require regular maintenance to maximize their service life. Periodic inspections for signs of wear, corrosion, or mechanical damage allow for timely interventions, preventing minor issues from escalating into significant problems.

Implementing a maintenance schedule that includes cleaning, touch-up painting, and protective treatments can significantly extend the lifespan of structures utilizing PPGL steel coils. In environments with high exposure to corrosive elements, such as coastal areas, more frequent inspections and maintenance may be necessary to ensure optimal performance.

Real-World Application: A Case Study in Coastal Construction

In a recent coastal construction project, our team utilized PPGL steel coils with a PVDF coating and DX53D substrate to build a series of residential units. Given the harsh marine environment, material selection was critical. After five years, inspections revealed minimal signs of corrosion or color fading, validating the effectiveness of our material choices and maintenance practices.

This experience underscores the importance of selecting high-quality PPGL steel coils and adhering to recommended maintenance protocols to achieve long-term durability, even in challenging environments.

Comparative Analysis: PPGL vs. PPGI Steel Coils

Understanding the differences between PPGL (Pre-painted Galvalume) and PPGI (Pre-painted Galvanized Iron) steel coils is essential for selecting the appropriate material for specific applications.

| Feature | PPGL Steel Coils | PPGI Steel Coils |

|---|---|---|

| Coating Composition | 55% 鋁, 43.5% Zinc, 1.5% Silicon | 100% Zinc |

| 耐腐蝕性 | Superior, especially in coastal areas | 緩和, less effective in saline environments |

| UV Resistance | 高的, especially with PVDF coatings | 緩和 |

| Lifespan | Up to 3 times longer than PPGI | Shorter lifespan |

| Cost | Slightly higher | Generally lower |

| Ideal Applications | Coastal buildings, industrial facilities | Interior structures, less corrosive environments |

This comparison highlights the advantages of PPGL steel coils in terms of durability and suitability for harsh environments, justifying their slightly higher cost in exchange for longer service life and reduced maintenance needs.

Step-by-Step Guide: Selecting the Right PPGL Steel Coil

Choosing the appropriate PPGL steel coil involves several critical steps:

-

Assess Environmental Conditions: Determine the exposure level to elements like humidity, salinity, and UV radiation.

-

Select Suitable Coating: Choose between PVDF, SMP, or other coatings based on environmental assessments.

-

Determine Substrate Grade: Select the appropriate steel grade (e.g., DX51D, DX52D) based on required mechanical properties.

-

Specify Coating Thickness: Ensure the metallic and paint coatings meet the necessary thickness for durability.

-

Verify Manufacturer Credentials: Choose suppliers with certifications like ISO 9001 and proven track records.

-

Request Samples: Obtain material samples to assess quality and compatibility with your project requirements.

-

Review Warranty and Support: Ensure the supplier offers adequate warranty and post-purchase support.

⚠️ Common Misconceptions About PPGL Steel Coils

-

“All PPGL Coils Are the Same”: Variations in coating composition, paint systems, and substrate grades can significantly impact performance.

-

“Higher Price Equals Better Quality”: While cost can reflect quality, it’s essential to assess the specific properties and certifications of the product.

-

“Maintenance Is Unnecessary”: Regular inspections and maintenance are crucial, even for high-quality PPGL steel coils, to ensure longevity.

結論: Maximizing Durability with Informed Choices

The durability of PPGL steel coils hinges on multiple factors, including coating composition, paint systems, substrate selection, manufacturing processes, and maintenance practices. By understanding and applying these industry secrets, stakeholders can make informed decisions that enhance the longevity and performance of their structures.

For those seeking reliable and high-quality PPGL steel coils, Shanxi Luokaiwei Steel Company offers a range of products tailored to meet diverse project requirements. With a commitment to excellence and customer satisfaction, they provide materials that stand the test of time.

📧 接觸: sales@luokaiweipipe.com

✅ PPGL Steel Coil Selection Checklist

-

Evaluate environmental exposure levels.

-

Choose appropriate coating type (PVDF, SMP, etc.).

-

Select suitable substrate grade (DX51D, DX52D, etc.).

-

Confirm coating thickness specifications.

-

Verify manufacturer certifications and reputation.

-

Request and assess product samples.

-

Review warranty terms and support services.

-

Establish a maintenance and inspection schedule.

By following this checklist, you can ensure the selection of PPGL steel coils that offer superior durability and performance for your specific applications.