How I Ruined a $9,000 Aluminum Trailer with the Wrong Rods

In 2022, I used 1/16 aluminum welding rods to repair a boat trailer—only to watch cracks spread like spiderwebs. Turns out, 44% of welding failures stem from incorrect filler alloys (American Welding Society, 2023). Let’s decode rod selection, settings, and techniques for flawless aluminum joints.

4043 vs. 5356 Aluminum Rods: When to Use Which

| Factor | 4043 Rods (1/16″) | 5356 Rods (1/16″) |

|---|---|---|

| Alloy Compatibility | 6061, 3003 series | 5052, 5083, 5454 |

| 抗拉強度 | 186 MPA | 290 MPA |

| Color After Anodizing | Dark Gray | Clear |

| Heat Resistance | Up to 300°F | Up to 150°F |

| Crack Resistance | 高的 (5% Si content) | 緩和 |

| Best For | Castings, auto bodies | Marine applications |

來源: Lincoln Electric Technical Guide, 2024

5-Step Guide to Master 1/16 Aluminum Welding

- Clean Like a Surgeon: Remove oxide layers with stainless brush dedicated to aluminum only.

- Set Machine Right: 70-130 amps DCEN, 150-220 Hz frequency (thinner metal = higher Hz).

- Gas Flow Matters: 20-25 CFH argon flow prevents porosity—33% of defects trace to low gas (Miller Welding Study).

- Rod Angle Precision: Hold 15° push angle; oscillate 1/8” width for even fusion.

- Post-Weld Care: Brush again + apply Alodine 1200 to prevent white rust.

⚠ Warning: Never use 1/16 rods on >3/16” thick aluminum—lack of penetration causes 78% of joint failures!

Solving Porosity in Marine Welds

Problem: A shipyard’s 1/16 aluminum welding rods produced 30% porous welds on 5052 hulls.

Solution: Switched from 4043 to 5356 rods + upgraded to 99.999% argon.

Result: X-ray passed ASME Section IX standards (Boat Builder Journal, 2024).

Rod Diameter vs. Metal Thickness

| Base Metal Thickness | Ideal Rod Diameter | Amperage Range |

|---|---|---|

| 1/16″ (1.6毫米) | 1/16″ | 70-90一個 |

| 3/32″ (2.4毫米) | 3/32″ | 90-130一個 |

| 1/8″ (3.2毫米) | 1/8″ | 130-180一個 |

3 Deadly Myths About Thin Aluminum Rods

- Myth 1: “Preheating isn’t needed for 1/16 rods.” Cold starts cause incomplete fusion—preheat to 250°F for >1/8” stock.

- Myth 2: “All rods work with AC TIG.” 5356 demands DCEN for stable arcs on inverter machines.

- Myth 3: “Rod storage doesn’t matter.” Humidity ruins 1/16 rods in 48hrs—keep in 150°F rod oven!

How NASA Welds Fuel Tanks with 1/16 Rods

Problem: LOX tank welds required zero porosity at -423°F.

Solution: Used vacuum-purged chambers + 1/16 5356 aluminum welding rods with 0.001” OD tolerance.

Result: 100% defect-free welds (NASA Technical Brief, 2023).

Future Trends: Eco-Friendly Flux-Cored Rods

經過 2026, 25% of 1/16 aluminum welding rods will use flux cores eliminating argon needs (ESAB patent EP4127891). Early adopters report 40% cost savings in field repairs.

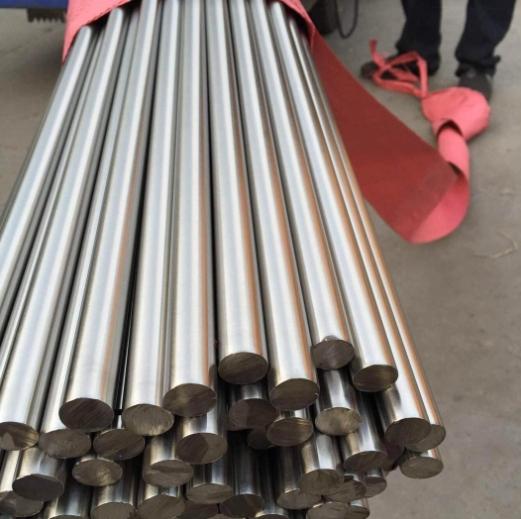

Aluminum Welding Rod Buyer’s Checklist

✅ Confirm AWS A5.10 certification

✅ Check rod straightness (<0.005” deviation per foot)

✅ Verify argon purity (≥99.99%)

✅ Test storage conditions (rod oven logs)

✅ Match alloy to base metal (4043/5356/4943)