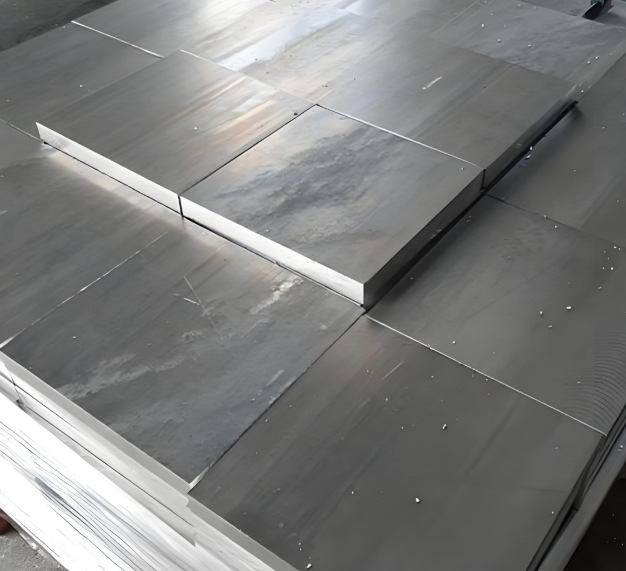

The 3A21 aluminum plate is a widely used alloy, renowned for its balance of strength, corrosion resistance, and formability. This article will explore the core properties of 3A21 aluminum plate, offering insights into its practical applications and common misconceptions. Whether you’re in the manufacturing, automotive, or aerospace industries, understanding the properties of this alloy can help you make better decisions in material selection.

📊 1. What is 3A21 Aluminum Plate?

3A21 aluminum plate is an alloy primarily composed of aluminum with small amounts of manganese. This alloy is known for its medium-strength, good corrosion resistance, and excellent weldability. It is part of the 3000 series of aluminum alloys, which are primarily characterized by their high resistance to corrosion, making them ideal for outdoor and marine environments.

-

Key Composition: The 3A21 aluminum plate typically contains around 1-1.5% manganese, which gives it improved strength compared to pure aluminum, while retaining excellent ductility.

-

Standard Uses: Common in applications where medium-strength properties are required, such as roofing, siding, and heat exchangers.

💪 2. Strength and Durability of 3A21 Aluminum Plate

One of the standout features of 3A21 aluminum plate is its moderate strength, which makes it suitable for many structural applications without being too heavy. However, compared to other aluminum alloys, it’s not as strong as high-strength alloys like 7075 aluminum.

Strength Comparison (3A21 vs. 7075 鋁板):

| 財產 | 3A21 Aluminum Plate | 7075 鋁板 |

|---|---|---|

| Yield Strength (MPA) | 160-210 | 503 |

| Ultimate Tensile Strength (MPA) | 250-300 | 572 |

| Density (g/cm³) | 2.73 | 2.81 |

As shown in the table, 3A21 aluminum plate has lower tensile and yield strengths compared to 7075, but it’s more affordable and easier to form. This makes 3A21 a better choice for non-critical applications where weight savings and high strength aren’t the primary concerns.

⚙️ 3. 耐腐蝕性

3A21 aluminum plate offers excellent corrosion resistance, especially in marine and coastal environments. The manganese content in the alloy enhances its resistance to corrosion, particularly pitting corrosion and stress corrosion cracking.

-

Marine Applications: The corrosion resistance of 3A21 makes it an excellent choice for boat hulls, maritime equipment, and coastal structures.

-

Real-World Example: In a 2018 study on aluminum alloys used in shipbuilding, 3A21 demonstrated superior corrosion resistance in saltwater environments compared to other alloys in the 3000 series (來源: Journal of Material Science).

However, it’s important to note that while it performs well in most environments, it may not be suitable for applications requiring extreme resistance to acidic or alkaline conditions.

🛠️ 4. Fabrication and Weldability

Another notable feature of 3A21 aluminum plate is its excellent formability and weldability. This makes it a popular choice for industries that require extensive fabrication, such as in automotive body parts or manufacturing equipment.

Common Fabrication Techniques:

-

Cutting: Laser cutting, plasma cutting, and shearing are all effective methods for processing 3A21 aluminum.

-

Welding: MIG and TIG welding are commonly used for 3A21. Its weldability is one of the key reasons it’s favored in the production of large welded structures.

-

Bending and Forming: 3A21 can be easily bent and formed without cracking, even at lower temperatures.

⚠️ 5. Common Misconceptions About 3A21 Aluminum Plate

-

Misconception #1: “3A21 aluminum plate is as strong as 7075 aluminum.”

-

Reality: 3A21 has lower strength, making it unsuitable for applications requiring high strength but ideal for medium-duty applications.

-

-

Misconception #2: “3A21 aluminum is resistant to all types of corrosion.”

-

Reality: While it offers great resistance to saltwater and mild environments, it does not perform well in extreme acidic or alkaline conditions.

-

-

Misconception #3: “3A21 aluminum plate is difficult to weld.”

-

Reality: 3A21 aluminum is highly weldable and often used in applications requiring high-quality welding, such as pressure vessels and chemical storage tanks.

-

📝 6. How to Choose the Right 3A21 Aluminum Plate for Your Project?

Choosing the right 3A21 aluminum plate for your project depends on several factors. Here’s a step-by-step guide:

Step 1: Identify the Application

-

Consider whether your application requires strength, corrosion resistance, or formability. 3A21 is great for moderate strength and superior corrosion resistance in less demanding structural applications.

Step 2: Assess Environmental Conditions

-

If the application will be exposed to harsh weather, marine conditions, or high humidity, 3A21 is a good choice due to its corrosion resistance.

Step 3: Evaluate Fabrication Needs

-

If your project requires extensive welding or forming, 3A21 is a great option because it has excellent formability and weldability.

Step 4: Consider Thickness and Dimensions

-

Standard thicknesses range from 1mm to 150mm. Choose a thickness that meets the mechanical strength requirements of your project.

Step 5: Review Cost-Effectiveness

-

3A21 aluminum plate is cost-effective compared to higher-strength alloys like 7075, so consider it for applications where cost is a crucial factor.

✅ Practical Checklist for Using 3A21 Aluminum Plate

-

Check Strength Requirements: Ensure the strength of 3A21 is adequate for your project needs.

-

Review Corrosion Resistance: Confirm that the material’s corrosion resistance meets the environmental challenges of your application.

-

Determine Welding Needs: Ensure that 3A21’s welding properties align with your fabrication requirements.

-

Select Proper Thickness: Match the plate thickness to the load-bearing requirements of your design.

-

Assess Cost Efficiency: Compare the cost of 3A21 to other materials with similar properties.

結論

The 3A21 aluminum plate is a versatile and reliable material suitable for a wide range of applications, especially when corrosion resistance, formability, and moderate strength are required. However, it is important to understand its limitations in terms of strength and resistance to extreme environmental conditions. By considering your specific needs and following the steps outlined in this article, you can make the best choice when selecting 3A21 aluminum plate for your project.

For high-quality 3A21 aluminum plates tailored to your manufacturing needs, reach out to Shanxi Luokaiwei Steel Company. With years of expertise and a focus on customer satisfaction, they can meet all your material requirements.

📧 Email: sales@luokaiweipipe.com

📱 WhatsApp: +86 18912200505