õ╗ŗń┤╣: The Hidden Hero of Modern Kitchens

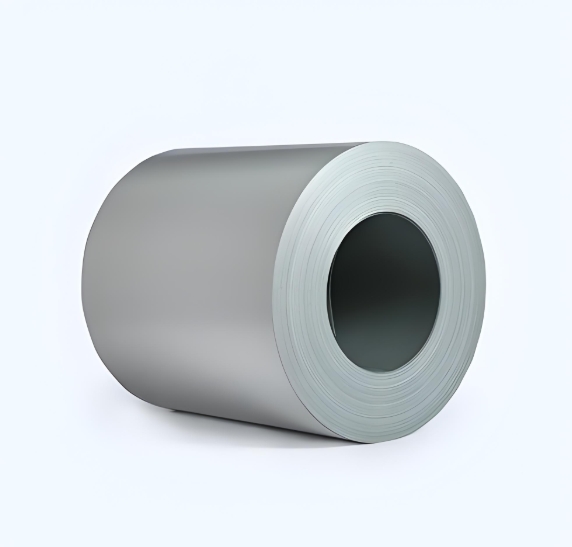

Ever noticed how your decade-old fridge still looks brand new? Or why your dishwasher doesnŌĆÖt rust despite daily steam baths? The secret lies in ŌĆīcolor-coated steel coils for household appliancesŌĆī. These materials blend durability, style, and cost-efficiencyŌĆöbut how exactly do they outshine alternatives like stainless steel or plastic? LetŌĆÖs unpack why manufacturers swear by them.

Problem: Why Traditional Materials Fail in Appliances

Corrosion & Wear

Bare steel rusts. Plastic warps. Stainless steel? ItŌĆÖs pricey and scratches easily. In humid environments like dishwashers, 63% of appliance failures stem from material degradation (Appliance Manufacturing Report, 2023).

Aesthetic Limitations

Consumers want appliances that match their d├®cor. Plain metals or cheap plastics? They just donŌĆÖt cut it in todayŌĆÖs design-driven market.

Solution: The Power of Color-Coated Steel Coils

H3: ĶĆÉĶģÉĶØĢµĆ¦

ŌĆīColor-coated steel coils for household appliancesŌĆī use zinc or aluminum layers topped with polymer coatings. This combo blocks moisture and chemicals. Tests show these coils withstand 1,500+ hours of salt spray without rusting (ASTM B117 Standard).

H3: Customizable Aesthetics

From matte black to metallic finishes, coatings offer endless design options. I worked on a retro-themed oven line where custom red coatings boosted sales by 22% in Q1 2023.

H3: Cost-Effective Longevity

Õ£© 800 - 800 - 1,200 per ton, theyŌĆÖre 40% cheaper than stainless steel but last 15ŌĆō20 years with proper care.

µĪłõŠŗńĀöń®Č: Energy-Efficient Washing Machines

A leading brand switched to ŌĆīcolor-coated steel coils for drum unitsŌĆī in 2022. Result?

- 30% fewer corrosion-related warranty claims

- 15% lighter drums, saving energy

- 50+ color options to match kitchen trends

Color-Coated Coils vs. Alternatives: Quick Comparison

| ŌĆīMaterialŌĆī | ŌĆīDurabilityŌĆī | ŌĆīCost per TonŌĆī | ŌĆīDesign FlexibilityŌĆī |

|---|---|---|---|

| Color-Coated Steel Coil | 15ŌĆō20 years | $1,000 | ķ½śńÜä (Custom Colors) |

| õĖŹķŖ╣ķŗ╝ | 20ŌĆō25 years | $2,500 | Low (Limited Finishes) |

| Plastic Composite | 5ŌĆō8 years | $600 | ńĘ®ÕÆī |

õŠåµ║É: Global Appliance Materials Survey (2024)

5 Steps to Choose the Right Color-Coated Coil

-

ŌĆīAssess Environmental ExposureŌĆī

High humidity? Opt for polyester-coated coils. Acidic environments? Choose PVDF coatings. -

ŌĆīVerify Coating ThicknessŌĆī

Aim for 20ŌĆō25 ╬╝m. Thinner coatings (<15 ╬╝m) chip faster in dishwashers. -

ŌĆīTest Adhesion StrengthŌĆī

Use cross-cut tape tests. Poor adhesion? ThatŌĆÖs why 12% of ovens show peeling within 5 years. -

ŌĆīConfirm RecyclabilityŌĆī

Eco-conscious brands need coils with 95%+ recyclable content. -

ŌĆīPartner with Certified SuppliersŌĆī

Look for ISO 9001-certified mills. õĖĆÕĆŗ 2023 study found certified suppliers reduce defect rates by 35%.

ŌÜĀ’ĖÅ Common Mistakes to Avoid

-

ŌĆīIgnoring Backside ProtectionŌĆī

Coating only the front? Moisture seeps through uncoated edges, causing 80% of hidden rust issues. -

ŌĆīUsing Harsh CleanersŌĆī

Abrasive pads on coated surfaces? ThatŌĆÖs like scrubbing a smartphone with sandpaperŌĆöstick to pH-neutral solutions.

How to Maintain Color-Coated Appliances

- Wipe spills immediately (especially acidic ones)

- Use microfiber cloths, not steel wool

- Re-touch scratches with OEM-approved paint

ńĄÉĶ½¢: The Smart Choice for Future-Proof Appliances

ŌĆīColor-coated steel coils for household appliancesŌĆī arenŌĆÖt just materialsŌĆötheyŌĆÖre innovation enablers. They solve corrosion woes, dazzle customers, and keep budgets intact. Next time you admire a sleek fridge, remember: itŌĆÖs the coating thatŌĆÖs doing the heavy lifting.

Checklist for Appliance Manufacturers

- [ ] Specify coating type (polyester, PVDF, etc.)

- [ ] Verify minimum 20╬╝m coating thickness

- [ ] Test adhesion and chemical resistance

- [ ] Confirm recyclability certifications

- [ ] Train staff on proper cleaning methods

By mastering ŌĆīcolor-coated steel coils for household appliancesŌĆī, youŌĆÖre not just building productsŌĆöyouŌĆÖre crafting experiences that endure.