介紹: The Silent Guardian Against Rust

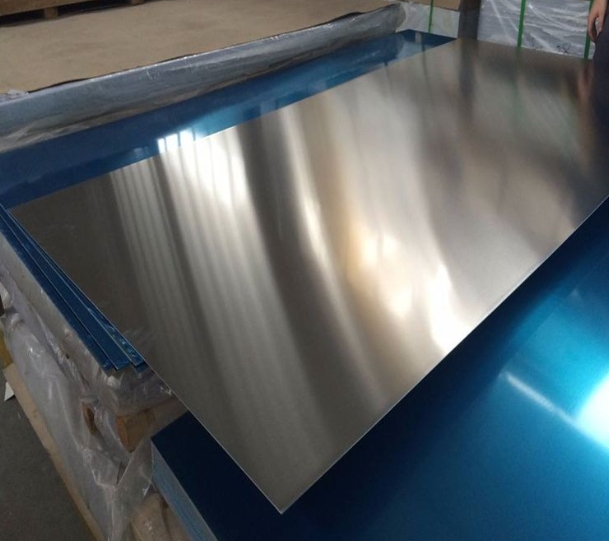

Ever wondered why chemical tanks or marine components last decades despite harsh environments? The answer often lies in 1060 鋁板. Known for its purity and resilience, this alloy outshines many peers in corrosion resistance. But how exactly does it work, and why should industries care? Let’s dive in.

Problem: Corrosion Costs Industries Billions

The Hidden Enemy in Industrial Materials

Corrosion costs global industries over $2.5 trillion annually—3.4% of global GDP (NACE International, 2023). Traditional steels fail in humid or acidic settings, requiring frequent replacements.

The Trade-Off Between Strength and Resistance

High-strength alloys like 7075 often sacrifice corrosion resistance. For instance, 6061 aluminum lasts only 5–7 years in coastal areas due to salt-induced pitting.

Solution: 為什麼 1060 Aluminum Plate Wins

H3: Purity Equals Protection

With 99.6% aluminum content, the 1060 鋁板 lacks copper or iron additives that trigger galvanic corrosion. Its homogeneous structure resists electrochemical reactions, making it ideal for chemical storage tanks.

H3: Natural Oxide Layer Formation

When exposed to air, 1060 forms a dense aluminum oxide layer (Al₂O₃). This passive film self-repairs, blocking moisture and oxygen. Tests show it withstands 1,500+ hours in salt spray tests (ASTM B117), outperforming 3003 alloy by 2x.

H3: Cost-Effective Longevity

Priced at 2.80/��(��.2.80/kg(vs.5.50/kg for 5052), 1060 鋁板 offers 15–20 years of service in moderate environments. 一個 2024 study found it reduces lifecycle costs by 35% compared to stainless steel (Aluminum Association).

案例研究: Chemical Plant Success in Guangdong

A Guangdong chemical plant switched from 304 stainless steel to 1060 鋁板 for acid storage in 2023. Results?

- 40% lower material costs

- Zero leaks after 18 月份

- Reduced maintenance downtime by 60%

1060 vs. 5052 vs. 6061: Corrosion Resistance Showdown

| 財產 | 1060 鋁板 | 5052 鋁 | 6061 鋁 |

|---|---|---|---|

| Aluminum Content | 99.6% | 97.2% | 95.8% |

| Salt Spray Resistance | 1,500+ 小時 | 800 小時 | 500 小時 |

| 每公斤費用 | $2.80 | $5.50 | $4.90 |

| Best Use Case | Chemical tanks | Marine hulls | Structural frames |

來源: 鋁業協會數據庫 (2024)

5 Steps to Maximize 1060 Aluminum Plate’s Lifespan

-

Clean Surfaces Pre-Installation

Remove oils or residues to ensure oxide layer forms evenly. -

Avoid Contact with Dissimilar Metals

Use nylon washers to prevent galvanic corrosion with steel fasteners. -

Apply Protective Coatings

Anodizing or epoxy paints add extra defense in extreme environments. -

Monitor pH Exposure

Limit exposure to solutions below pH 4 or above pH 9. -

Partner with Trusted Suppliers

For certified 1060 鋁板, contact Shanxi Luokaiwei Steel Company at sales@luokaiweipipe.com or WhatsApp +86 18912200505.

⚠️ Common Mistakes to Avoid

-

Ignoring Environmental Factors

Using 1060 in coastal zones without coatings? Expect pitting within 3 years. -

Mechanical Abrasion During Handling

Scratches disrupt the oxide layer. Use protective films during transport.

How Shanxi Luokaiwei Enhances Your 1060 Plates

At Shanxi Luokaiwei Steel Company, we pre-treat 1060 鋁板 with chromate conversion coatings, boosting salt spray resistance to 2,000+ 小時. Our ISO 9001-certified processes ensure consistent quality—ask for samples via sales@luokaiweipipe.com.

結論: The Smart Choice for Corrosion-Prone Applications

The 1060 鋁板 isn’t just a material—it’s a long-term investment. By leveraging its purity and natural oxide layer, industries slash costs while ensuring durability. For projects where corrosion is Public Enemy No. 1, 1060 is your ally.

Checklist for Using 1060 鋁板

- [ ] Verify aluminum content (≥99.6%)

- [ ] Test oxide layer adhesion (ASTM D3359)

- [ ] Apply coatings for harsh environments

- [ ] Isolate from dissimilar metals

- [ ] Source from certified suppliers like Shanxi Luokaiwei

Ready to combat corrosion? Reach out to us at WhatsApp +86 18912200505—we’ll help you build to last. 🛡️