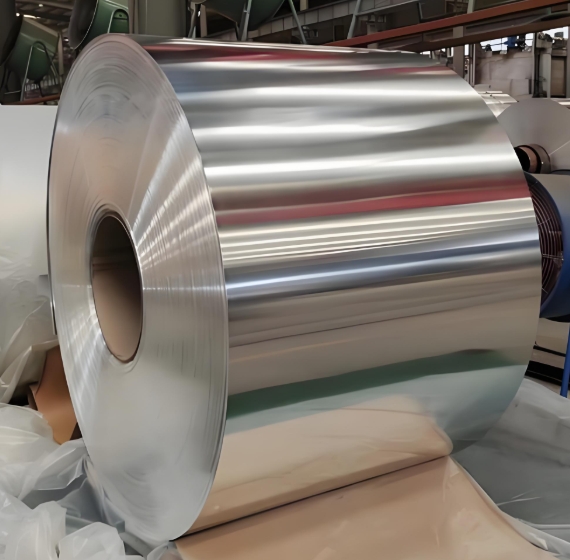

5A05海洋鋁線圈: Unveiling Its Superiority in Saltwater Corrosion Resistance.

When it comes to marine applications, selecting the right materials is crucial for ensuring longevity and performance. Among the various options available, the 5A05海洋鋁線圈 stands out due to its exceptional resistance to saltwater corrosion. This article delves into the reasons behind the popularity of 5A05 aluminum coils in marine environments, comparing them with other alloys, and providing practical insights for their application.

🧪 What Makes 5A05 Marine Aluminum Coil Ideal for Marine Environments?

✅ Superior Corrosion Resistance

The 5A05 alloy, primarily composed of aluminum with magnesium and manganese, exhibits remarkable resistance to corrosion, especially in saltwater conditions. This property makes it highly suitable for marine applications where exposure to seawater is constant. According to Chalco Aluminum, marine-grade aluminum alloys like 5A05 offer excellent seawater corrosion resistance, ensuring durability and longevity in marine environments.

⚙️ Lightweight and High Strength

Aluminum alloys are known for their lightweight nature, and 5A05 is no exception. This characteristic reduces the overall weight of marine vessels, leading to improved fuel efficiency and easier handling. Despite its lightness, 5A05 maintains a high strength-to-weight ratio, making it ideal for structural components that require both strength and reduced weight.

🔧 Excellent Workability

5A05 aluminum coils are favored for their excellent workability. They can be easily welded, machined, and formed into various shapes, facilitating the manufacturing process of marine structures. This versatility allows for the production of complex components without compromising the material’s integrity.

📊 5A05 vs. Other Marine Aluminum Alloys: A Comparative Analysis

| 財產 | 5A05 | 5083 | 6061 |

|---|---|---|---|

| 耐腐蝕性 | 出色的 | Superior | 好的 |

| Strength | 高的 | Very High | 緩和 |

| Workability | 出色的 | 好的 | 出色的 |

| Weight | Lightweight | Lightweight | Lightweight |

| Cost | 緩和 | 高的 | 緩和 |

As seen in the table, while 5083 offers superior corrosion resistance, 5A05 provides a balanced combination of corrosion resistance, strength, and workability at a more moderate cost. 6061, on the other hand, offers excellent workability but falls short in corrosion resistance compared to 5A05.

🛠️ Practical Applications of 5A05 Marine Aluminum Coil

🚢 Shipbuilding

5A05 aluminum coils are extensively used in shipbuilding for constructing hulls, decks, and other structural components. Their resistance to saltwater corrosion ensures the longevity of vessels, reducing maintenance costs and downtime.

⚓ Marine Equipment

Marine equipment such as railings, ladders, and supports are often fabricated using 5A05 aluminum coils. The alloy’s lightweight nature makes these components easy to handle and install, while its strength ensures safety and durability.

🛠️ Structural Components

In addition to shipbuilding, 5A05 aluminum coils are used in manufacturing structural components for docks, piers, and offshore platforms. Their ability to withstand harsh marine environments makes them suitable for these applications.

⚠️ Common Misconceptions About 5A05 Marine Aluminum Coil

❌ Misconception 1: All Aluminum Alloys Are the Same

Not all aluminum alloys possess the same properties. While 5A05 offers excellent corrosion resistance, other alloys may not perform as well in marine environments. It’s essential to choose the right alloy based on the specific requirements of the application.

❌ Misconception 2: Higher Strength Always Means Better Performance

While strength is crucial, it must be balanced with other factors like corrosion resistance and workability. An alloy with higher strength but poor corrosion resistance may not be suitable for marine applications.

❌ Misconception 3: Aluminum Is Prone to Corrosion in Saltwater

While aluminum can corrode, alloys like 5A05 are specifically designed to resist corrosion in saltwater environments. Proper treatment and maintenance further enhance their durability.

✅ Step-by-Step Guide to Utilizing 5A05 Marine Aluminum Coil in Shipbuilding

-

Material Selection: Choose 5A05 aluminum coil with the appropriate temper (e.g., H116) to meet the strength and corrosion resistance requirements.

-

Design Considerations: Incorporate design elements that minimize stress concentrations and allow for proper drainage to prevent water accumulation.

-

Fabrication: Use suitable welding techniques, such as TIG or MIG welding, to join 5A05 aluminum components, ensuring strong and corrosion-resistant joints.

-

Surface Treatment: Apply anodizing or other protective coatings to enhance the corrosion resistance of exposed surfaces.

-

Maintenance: Regularly inspect and clean aluminum components to remove salt deposits and prevent corrosion, ensuring the longevity of the structure.

✅ Practical Checklist for Implementing 5A05 Marine Aluminum Coil

-

Material Certification: Ensure the 5A05 aluminum coil meets relevant standards and certifications for marine applications.

-

Design Specifications: Verify that the design incorporates considerations for corrosion resistance and structural integrity.

-

Fabrication Quality: Confirm that welding and other fabrication processes are performed by qualified personnel using appropriate techniques.

-

Surface Protection: Implement surface treatments to enhance corrosion resistance, especially for components exposed to seawater.

-

Regular Maintenance: Establish a routine inspection and maintenance schedule to identify and address potential issues promptly.

🧠 Final Thoughts

The 5A05海洋鋁線圈 offers a balanced combination of corrosion resistance, strength, and workability, making it an excellent choice for marine applications. By understanding its properties and following best practices in its application, manufacturers can ensure the longevity and performance of marine structures. Whether you’re involved in shipbuilding, marine equipment fabrication, or offshore platform construction, 5A05 aluminum coils provide a reliable material solution for challenging marine environments.