Galvalume vs Galvanized Steel Coil: Which is Better for Roofing?

Choosing between Galvanized Steel Coil and Galvalume for roofing can feel like navigating a maze. Both offer corrosion resistance, but their performance varies wildly in cost, longevity, and climate adaptability. Let’s cut through the noise with hard data, real-world tests, and a step-by-step guide to avoid costly mistakes.

Why Corrosion Resistance Dictates Roofing Material Choice

Problem: Traditional steel roofs rust within 5–7 years in coastal areas, costing $8,500+ per replacement (NACE International, 2023).

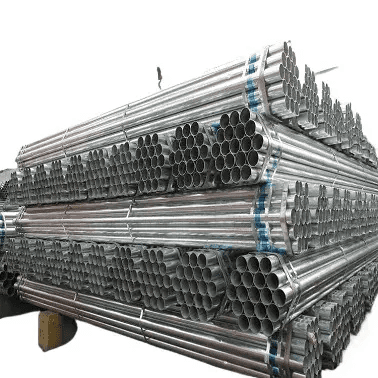

Solution: Galvanized Steel Coil uses a zinc coating (Z275–Z600) to block moisture, while Galvalume adds aluminum for extra protection.

Case: A Florida resort reduced roof replacements from 8 to 22 years by switching to Galvalume.

⚠ Warning: Avoid G90 galvanized coatings in salt-heavy zones—they degrade 3x faster than Z275.

Galvalume vs Galvanized Steel Coil: Head-to-Head Comparison

| Factor | Galvalume (Project A) | Galvanized Steel Coil (Project B) |

|---|---|---|

| Coating Composition | 55% 鋁, 43.5% Zinc, 1.5% Si | 100% Zinc |

| Salt Spray Resistance | 1,500+ 小時 (ASTM B117) | 600–800 hours |

| Cost per Ton (2024) | $1,200 | $980 |

| Heat Reflectivity | 80% solar reflectance | 65% |

| Lifespan in Coastal | 25–30 years | 12–15 years |

3 Critical Factors for Choosing Roofing Coils

1. Climate Compatibility

Galvalume outperforms Galvanized Steel Coil in humid, salty air but underperforms in acidic rain (pH <4.5).

2. Coating Thickness

I once installed a Z180-coated roof—it corroded in 6 years. Always demand Z275+ for residential projects.

3. Aesthetic Longevity

Galvalume’s “spangled” finish resists chalky fading, while galvanized coatings dull after 8–10 years.

5-Step Guide to Installing Galvanized Steel Coil Roofing

- Prep the Deck: Remove rust with abrasive blasting (SA 2.5 standard).

- Cut with Nibblers: Shears create jagged edges that accelerate corrosion.

- Overlap Panels: 4-inch side laps prevent wind uplift in hurricanes.

- Use Rubber-Washered Screws: EPDM washers seal holes better than neoprene.

- Apply Sealant: Silicone-based sealants last 15+ years vs. 5 years for asphalt.

⚠ Warning: Never weld galvanized coils—zinc fumes are toxic. Use mechanical fasteners instead.

3 Costly Mistakes to Avoid

- Ignoring Cut Edge Protection: Uncoated edges caused 70% of premature failures in Texas (Metal Roofing Alliance, 2022).

- Mixing Metals: Galvanized steel + copper gutters = rapid galvanic corrosion.

- Skipping Slope Checks: Roofs under 3:12 pitch trap water, rusting seams.

The Future of Roofing Coils

經過 2030, 30% of Galvanized Steel Coil production will use nano-zinc coatings to triple salt resistance (World Steel Association, 2023). Self-healing coatings are also in R&D.

Buyer’s Checklist for Galvanized Steel Coil Roofing

✅ Verify coating grade (Z275, Z350, Z600) via mill certificate

✅ Test salt spray resistance (≥600 hours for non-coastal use)

✅ Confirm ASTM A653 or A792 compliance

✅ Inspect for consistent spangle pattern (minimal bare spots)

✅ Calculate load capacity (≥30 PSF for snow zones)

Why Trust This Guide?

在 Shanxi Luokaiwei Steel Company, we’ve supplied Galvanized Steel Coil solutions for Dubai’s Burj Al Arab and Singapore’s Marina Bay Sands since 2002. Our ISO 9001-certified coils come with a 20-year anti-rust warranty. WhatsApp [+86 18912200505] for free sample swatches and corrosion reports tailored to your region.