CATEGORIES

FEATURED PRODUCTS

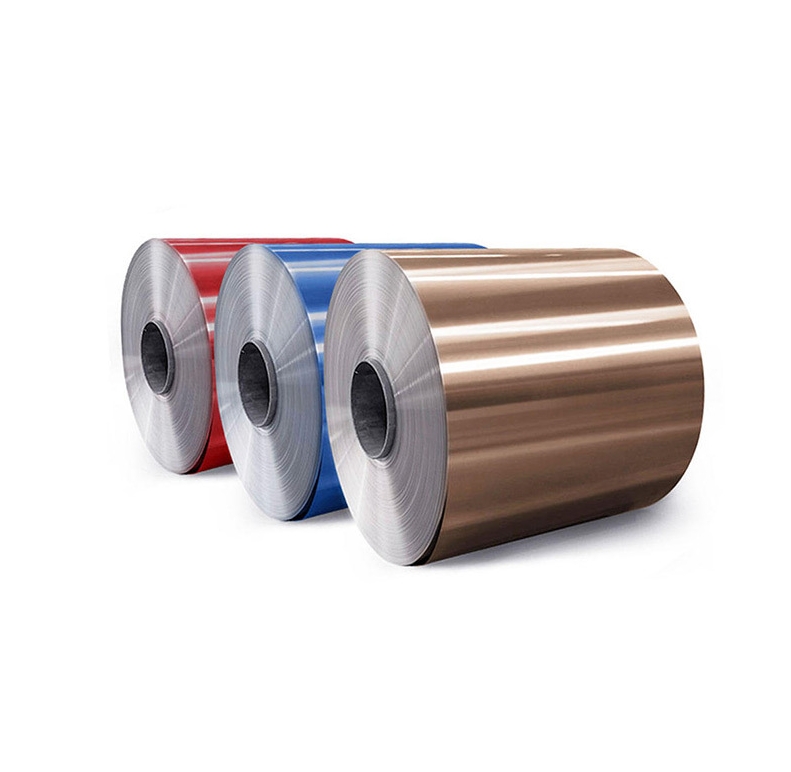

Color Coated Steel Coil for Household Appliances

Short Description:

Color Coated Steel Coils are high-gloss, pre-painted metal sheets engineered for appliance exteriors requiring scratch resistance (≥3H pencil hardness) and chemical resilience. Featuring dual-coat polyester-epoxy systems, these coils achieve 15+ years UV resistance (ASTM G154 Cycle 4) with 50+ RAL/Pantone color options. The frontside uses 30µm oil-free polyester resin for mirror-like finishes, while the backside applies 20µm modified epoxy to withstand detergent corrosion (pH 3–12).

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

Color Coated Steel Coil for Household Appliances Product Overview

Color Coated Steel Coils are high-gloss, pre-painted metal sheets engineered for appliance exteriors requiring scratch resistance (≥3H pencil hardness) and chemical resilience. Featuring dual-coat polyester-epoxy systems, these coils achieve 15+ years UV resistance (ASTM G154 Cycle 4) with 50+ RAL/Pantone color options. The frontside uses 30µm oil-free polyester resin for mirror-like finishes, while the backside applies 20µm modified epoxy to withstand detergent corrosion (pH 3–12).

Technical Specifications

1. Base Material & Dimensions

| Parameter | Specifications | ||

|---|---|---|---|

| Material Grades | EG (Electro-Galvanized): Z60–Z180 | GI (Hot-Dip): AZ50–AZ150 | CR (Cold-Rolled): SPCC–SPCE |

| Thickness | 0.15–0.7 mm (±0.02mm tolerance) | ||

| Width | 600–1,250 mm (slit-to-size capability) | ||

| Coil Weight | 3–10 tons (ID: 508/610 mm) |

2. Coating Properties

- Front Coating:

- Type: High-molecular linear polyester (PVDF alternatives available)

- Thickness: 10–30µm (2-coat system)

- Gloss Level: 80–95 GU (60° angle)

- Reverse Coating:

- Type: Epoxy-modified hybrid polymer

- Thickness: 5–25µm

- Adhesion: Class 1 (ISO 2409 cross-cut test)

3. Performance Metrics

| Test | Standard | Result |

|---|---|---|

| Salt Spray Resistance | ASTM B117 | 1,000h (no red rust) |

| Impact Resistance | ASTM D2794 | 50 kg·cm (direct impact) |

| Bending Flexibility | ISO 1519 | 2T (180° bend, no cracking) |

| Thermal Resistance | 120°C × 24h | No blistering/discoloration |

Key Advantages

- Surface Durability: 5,000+ Taber abrasion cycles (CS-10 wheel, 500g load)

- Hygienic Design: Smooth surface (Ra ≤0.3µm) inhibits bacterial growth (ISO 22196)

- Customization: Embossed patterns (leather, wood grain) + anti-fingerprint coatings

- Eco-Friendly: VOC content ≤50 g/L (GB 30981 compliance)

Applications

| Sector | Components | Recommended Thickness |

|---|---|---|

| Home Appliances | Refrigerator doors, oven panels, AC casings | 0.5–0.7mm (GI/AZ150) |

| Commercial | Vending machine bodies, freezer displays | 0.4–0.6mm (EG/Z120) |

| Electronics | TV backplates, speaker grilles | 0.3–0.5mm (CR/SPCE) |

Certifications & Compliance

- Quality: ISO 9001, IATF 16949 (automotive-grade)

- Safety: FDA CFR 21 (food contact surfaces), REACH SVHC <0.1%

- Sustainability: RoHS, LEED v4.1 MR credits