CATEGORIES

FEATURED PRODUCTS

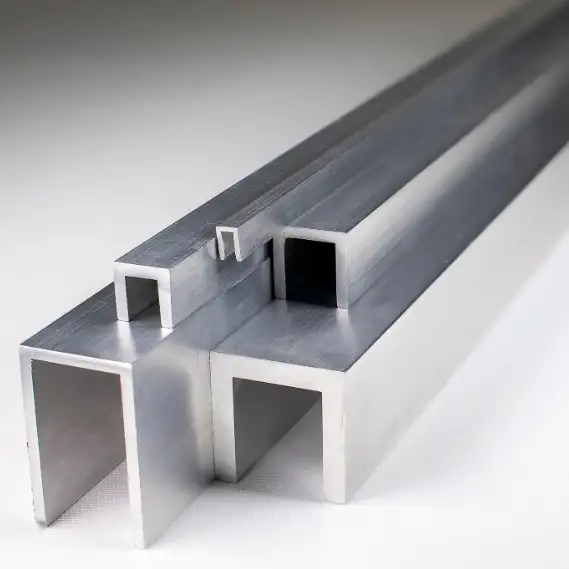

Aluminum U Bars

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

We manufacture and supply aluminum U bars for diverse structural needs. Our U channel aluminum exudes strength. It carries loads reliably. Yet it remains lightweight.

1. Overview of Aluminum U Bars

An aluminum U‑bar (also called aluminum U‑profile) features a U‑shaped cross section. It serves as a structural aluminum channel in construction, transport, and automation. We extrude it using high‑precision tooling. Then we cut to length. Customers value its corrosion resistance, machinability, and aesthetic finish. Moreover, aluminum U bars support turnkey solutions in framing, railings, and assemblies—a true value‑add. Nevertheless, you must choose the right alloy and temper to meet strength and environmental demands.

2. Alloy Grades and Designations

Aluminum U bars come in multiple alloy families. The most common include:

-

6xxx series (e.g., 6063, 6061, 6082) — popular for extrusion.

-

5xxx series (e.g., 5052, 5083) — marine and corrosion‑resistant grade.

-

2xxx & 7xxx series — aerospace‑grade, high strength.

| Alloy Series | Common Designations | Temper Options | Typical Use |

|---|---|---|---|

| 6xxx | 6063, 6061, 6082 | T5, T6, T52 | Architectural, framing, signage |

| 5xxx | 5052, 5083 | H32, H34 | Marine, pressure vessels |

| 2xxx/7xxx | 2024, 7075 | T3, T6 | Aerospace, military, high‑stress |

We focus on 6063‑T6 for its perfect blend of extrudability and strength. It’s often benchmarked against run‑of‑the‑mill steel channels for performance.

3. Chemical Composition

We analyze composition carefully. Table 1 compares 6063, 6061, and 6082 per ASTM B221.

Table 1: Chemical Composition (%) of Common Aluminum U Bars

| Element | 6063 | 6061 | 6082 |

|---|---|---|---|

| Si | 0.2–0.6 | 0.4–0.8 | 0.7–1.3 |

| Fe | 0.35 max | 0.7 max | 0.5 max |

| Cu | 0.1 max | 0.15–0.4 | 0.1 max |

| Mn | 0.1 max | 0.15 max | 0.4–1.0 |

| Mg | 0.45–0.9 | 0.8–1.2 | 0.6–1.2 |

| Zn | 0.1 max | 0.25 max | 0.2 max |

| Cr | 0.1 max | 0.04–0.35 | — |

| Others | 0.15 max | 0.15 max | 0.15 max |

These chemistries dictate performance. For instance, higher magnesium boosts strength, while silicon aids fluidity in extrusion.

4. Mechanical Properties and Strength Parameters

We rigorously test each batch. Typical properties for 6063‑T6 U bars are:

-

Tensile Strength: 190–240 MPa.

-

Yield Strength: ≥ 215 MPa (35 ksi) [1].

-

Elongation at Break: ≥ 8–12% [2].

(1) Aluminum Association, “Mechanical Properties of Aluminum and Aluminum Alloys,” 2024.

(2) ASTM B221-20 Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

The combination of tensile and yield values makes these profiles ideal for medium‑load structural frames. Furthermore, they outperform untreated steel in corrosion resistance—ideal for outdoor, marine, and office interiors.

5. Experimental Data and Testing Methods

We employ several tests:

-

Tensile Testing in accordance with ISO 6892.

-

Fatigue Testing per ASTM E466.

-

Corrosion Resistance in salt‑spray chambers (ASTM B117).

-

Dimensional Accuracy measured via laser scanning.

For example, our fatigue trials at ±50 MPa showed over 10^7 cycles without failure. Moreover, laser scans confirm tolerances within ±0.1 mm—benchmarked to industry yardsticks.

6. Dimension and Size Chart

Below is a sample size chart for 6063‑T6 U bars—customizable per order.

Table 2: Standard Dimensions of Aluminum U Bar (6063‑T6)

| Designation | Width (mm) | Height (mm) | Wall Thickness (mm) | Length (m) |

|---|---|---|---|---|

| U20×10×2 | 20 | 10 | 2 | 6 (up to 12 m) |

| U30×15×3 | 30 | 15 | 3 | 6 (up to 12 m) |

| U40×20×4 | 40 | 20 | 4 | 6 (up to 12 m) |

| U50×25×5 | 50 | 25 | 5 | 6 (up to 12 m) |

We also manufacture custom profiles per drawing—no turnkey solution is off the table.

7. Global Standards and Certifications

Our aluminum U bars comply with:

-

ASTM B221 (USA)

-

EN 755‑9 (EU)

-

GB/T 6892 (China)

-

JIS H4100 (Japan)

Certifications include ISO 9001, ISO 14001, and RoHS compliance. We coordinate factory audits, issue mill test reports, and guarantee traceability from ingot to profile.

8. Comparison with Other Aluminum Profiles

How do U channel aluminum profiles differ from C channels or T channels? Table 3 benchmarks mechanical and geometric distinctions.

Table 3: U Bar vs. C Channel vs. T Profile

| Feature | U Bar | C Channel | T Profile |

|---|---|---|---|

| Section Modulus | Medium | Low–Medium | Low |

| Moment of Inertia | Higher vs C and T | Lower | Lower |

| Material Usage | Economical | Minimal | Minimal |

| Application | Sliding tracks, frames | Brackets, rails | Joining flanges |

| Machinability | Excellent | Excellent | Good |

In many builds, aluminum U bars achieve a yardstick balance between strength and material efficiency—helpful for value‑add projects.

9. Purchasing Considerations for Aluminum U Bars

When you procure, consider:

-

Alloy & Temper: Match design loads.

-

Dimensional Tolerance: Check extruder capabilities.

-

Surface Finish: Mill finish, anodized, powder coated.

-

Certification: Insist on MTR, QQ‑Q‑A‑250/11.

-

Supply Chain: Lead times can vary—plan ahead.

Moreover, always request samples for bench testing. A run‑of‑the‑mill assumption can cost time. Nevertheless, partnering with a reliable mill like Luokaiwei eases logistics and quality checks.

10. Why Choose Luokaiwei

We at Luokaiwei extrude over 10,000 tons annually. Our global logistics ensure rapid delivery in days, not weeks. We offer:

-

Factory‑direct pricing.

-

24‑hour quotation service.

-

Custom tooling with low minimum orders.

Our MTRs and process audits exceed industry norms. In short, we provide a turnkey, value‑add solution for all your aluminum U‑profile needs.

11. Case Study: Structural Application of Aluminum U Bar

Project: Modular Exhibition Booth Frame, Germany.

Challenge: Lightweight yet rigid frames for frequent assembly.

Solution: We supplied 6063‑T6 U bars (U40×20×4) in custom lengths with anodized finish.

Outcome:

-

Frame weight: 25% less than steel alternative.

-

Assembly time reduced by 20%.

-

No corrosion during 12 months of outdoor use.

Customer feedback praised our on‑time delivery and consistent tolerances—a classic benchmark for successful partnership.

12. Frequently Asked Questions

-

What are the main benefits of aluminum U bars?

Lightweight, corrosion‑resistant, excellent machinability, and high extrudability. -

Can I anodize or powder‑coat U channel aluminum?

Yes. Both finishes enhance corrosion resistance and aesthetic appeal. -

What is the typical lead time?

Standard profiles: 2–3 weeks. Custom tooling: 4–6 weeks. -

How do I choose between 6063 and 6061?

If you need higher strength, pick 6061‑T6; for better extrudability and finish, 6063‑T6. -

What quality certifications do you hold?

ISO 9001, ISO 14001, RoHS, ASTM and EN mills tests.