CATEGORIES

FEATURED PRODUCTS

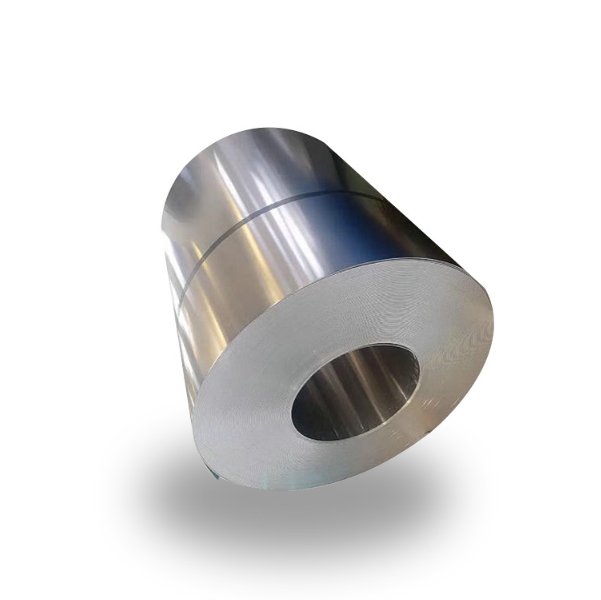

7075 Aluminum Coil

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

7075 Aluminum Alloy: The Ultimate High-Strength Aerospace-Grade Solution

Premium Zinc-Alloyed Aluminum for Extreme Performance

7075 aluminum alloy (UNS A97075) represents the pinnacle of high-strength aluminum alloys, with zinc (5.1-6.1%) as its primary alloying element. This heat-treatable alloy delivers exceptional mechanical properties, including a tensile strength of 572 MPa and yield strength of 503 MPa (per ASTM B209). While slightly less ductile than other aluminum alloys (11% elongation), it offers superior fatigue resistance – making it 40% stronger than 6061 alloy while maintaining 85% of its corrosion resistance.

Why 7075 Aluminum?

- Aerospace-Grade Strength: 503 MPa minimum yield strength (T6 temper)

- Fatigue Resistance: 10⁷ cycle endurance limit at 160 MPa

- Machinability: 70% relative to free-cutting brass

- Weight Savings: 30% lighter than steel at equivalent strength

Technical Specifications

1. Chemical Composition (ASTM B209 Standard)

| Element | Zn | Cu | Mg | Cr | Al |

|---|---|---|---|---|---|

| % Range | 5.1-6.1 | 1.2-2.0 | 2.1-2.9 | 0.18-0.28 | Balance |

Trace elements: Fe≤0.50%, Si≤0.40%, Ti≤0.20%

2. Mechanical Properties

| Temper | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| T6 | 572 | 503 | 11 | 175 |

| T73* | 505 | 435 | 13 | 150 |

T73 temper improves stress corrosion resistance

Test methods: ASTM E8 (tensile), ISO 6507-1 (hardness)

3. Physical Characteristics

| Parameter | Value | Unit |

|---|---|---|

| Density | 2.81 | g/cm³ |

| Melting Range | 475-635 | °C |

| CTE | 23.6×10⁻⁶ | /°C |

| Modulus | 71.7 | GPa |

Custom Manufacturing Options

Available Forms:

- Thickness: 0.5-150mm (±0.1mm tolerance)

- Width: 25-2500mm (custom slitting available)

- Length: Precision-cut up to 12 meters

Surface Finishes:

- Mill finish (standard Ra 0.8-1.6μm)

- Alodine coating (0.5-1.2μm)

- Hard anodizing (25-50μm)

Value-Added Services:

- CNC machining (±0.05mm accuracy)

- Heat treatment (T6/T73 temper)

- Laser cutting for complex geometries

Industrial Applications

Aerospace:

- Aircraft wing spars

- Landing gear components

- Spacecraft structural members

Defense:

- Military vehicle armor

- Missile components

- Weapon mounts

High-Performance:

- Bicycle frames

- Racing components

- Robotics arms

Performance Comparison

| Property | 7075 | 6061 | 2024 |

|---|---|---|---|

| Tensile (T6) | 572 MPa | 310 MPa | 469 MPa |

| Fatigue Limit | 160 MPa | 97 MPa | 138 MPa |

| Corrosion | Good | Excellent | Fair |

| Cost Index | 1.5 | 1.0 | 1.2 |

Fabrication Guidelines

Machining Tips:

- Use carbide tools (0.1mm/rev feed rate)

- Maintain cutting speeds below 300 SFM

- Apply coolant to prevent work hardening

Heat Treatment:

- Solution heat treat at 480°C (1 hour)

- Quench in water (20-30°C)

- Age harden at 120°C (24 hours)

Quality Assurance

- 100% ultrasonic inspection

- Third-party material certification

- Full traceability documentation

Certifications: AMS 4047, MIL-A-22771

Packaging: VCI-coated wooden crates

Lead Time: 10-18 days for certified material

Why 7075 Dominates Aerospace?

First, its zinc content enables exceptional strength. Second, copper enhances precipitation hardening. Moreover, chromium improves stress corrosion resistance. Additionally, strict aerospace certifications ensure reliability. Finally, proven performance justifies its premium cost.

For structural components, specify T6 temper. Marine environments benefit from T73. Regardless of application, 7075 delivers uncompromising performance.