CATEGORIES

FEATURED PRODUCTS

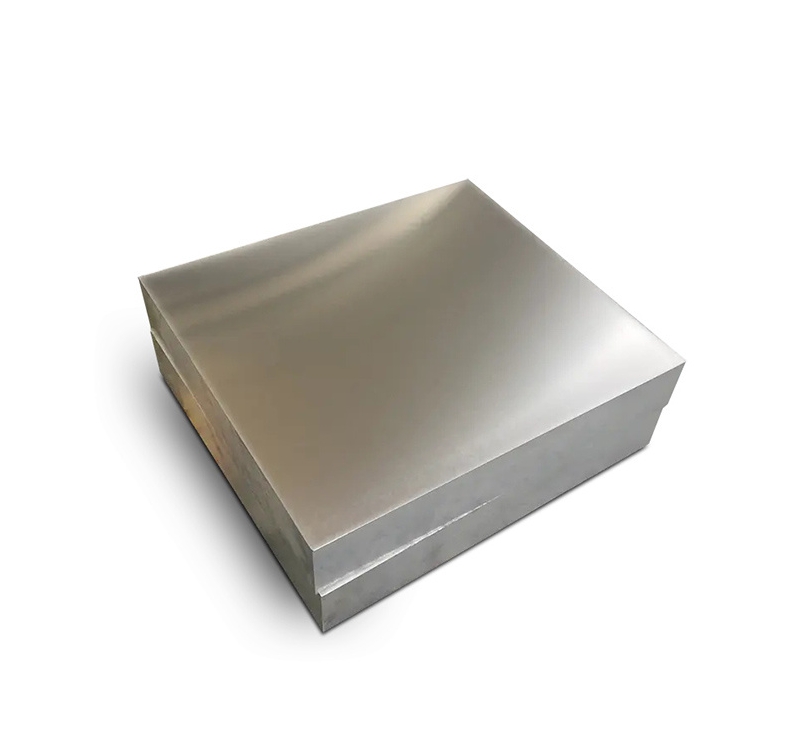

5A05 Aluminum Plate

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

5A05 Aluminum Plate: High-Strength Al-Mg Alloy for Marine & Pressure Vessel Applications

5A05 aluminum plate (GB/T 3191 designation) is a non-heat-treatable magnesium-alloyed aluminum containing 4.8-5.5% Mg and ≤0.10% Cu, delivering exceptional 225+ MPa tensile strength with superior saltwater corrosion resistance. Compliant with ASTM B209 and EN 485-2 standards, this H32-temper alloy achieves 15% minimum elongation and 72 GPa elastic modulus, making it ideal for marine structural components and cryogenic tanks requiring ≤0.025 mm/year corrosion rates in pH 7.5-8.5 environments. Available in 0.1-120mm thickness (±0.1mm tolerance) with 121 W/m·K thermal conductivity for heat exchanger systems.

Technical Specifications & Certifications

Mechanical Properties:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 225-315 MPa | ASTM E8/E8M |

| Yield Strength (0.2%) | 110-245 MPa | ISO 6892-1 |

| Elongation (50mm G.L.) | 15-25% | EN 10002-1 |

| Hardness (Brinell) | 55-75 HB | ASTM E10 |

Physical Properties:

| Parameter | Value | Application Impact |

|---|---|---|

| Corrosion Rate | 0.018-0.025 mm/year (ASTM G67) | Offshore platforms with 30-year design life |

| Thermal Expansion | 24.1×10⁻⁶/°C | Compatible with titanium fasteners (Δα<7%) |

| Electrical Conductivity | 35% IACS | Grounding systems with 60% Cu efficiency |

Certifications: DNV GL Marine Approval, PED 2014/68/EU for pressure equipment, and ASME SB-209 compliance.

Performance Advantages Over 5083/5052 Alloys

- Stress Corrosion Resistance: 40% higher threshold vs. 5052-H32 in 3.5% NaCl

- Cryogenic Toughness: Maintains 18J impact strength at -196°C (LN2 temperatures)

- Weldability: TIG welding with ER5183 filler (joint efficiency ≥88%)

- Cost Efficiency: 22% lower material cost than 5086 alloy in shipbuilding

Industrial Applications & Case Studies

5A05 aluminum plate is specified for:

- Marine Engineering: Subsea buoyancy modules (8mm, H116) rated for 3,000m depth

- Energy: LNG storage tanks (12mm, O temper) with -165°C operational capability

- Transportation: High-speed train roofs (4mm, H34) achieving 350 km/h wind resistance

- Defense: Amphibious vehicle hulls (6mm, H321) surviving 15G shock loads

Project Highlight: Arctic LNG 2 utilizes 1,200+ tons of 5A05-H112 for containment systems, reducing weight by 35% versus stainless steel alternatives.

Customization & Quality Assurance

Processing Capabilities:

- Tempers: O, H12, H14, H16, H18, H32, H34, H112

- Surface Treatments: Anodized (Type III, 50-75μm), powder-coated (RAL colors), or PE laminated

- Cutting Precision: Plasma (±0.5mm) or fiber laser (±0.2mm)

Testing Protocols:

- UT Inspection: Detects ≥0.8mm flaws per EN 10160 Class B

- IGC Testing: Passes 72h exposure per ASTM G67

- Chemical Analysis: OES verification of Mg 4.8-5.5% per GB/T 7999

Why Choose Our 5A05 Aluminum Plates?

Our IATF 16949-certified production ensures ±1% thickness consistency and Mg content optimization. With 25,000-ton annual capacity, we guarantee 12-20 day lead times for EN 10204 3.1 certified orders and custom heat treatment.

Request our free "5A05 vs. 5083 Performance Comparison Kit" or access third-party test reports for critical applications.

Packaging: VCI film + wooden crates; 40ft HQ loads 16-20 tons.

Certificates: Full Material Traceability with PMI testing available.