CATEGORIES

FEATURED PRODUCTS

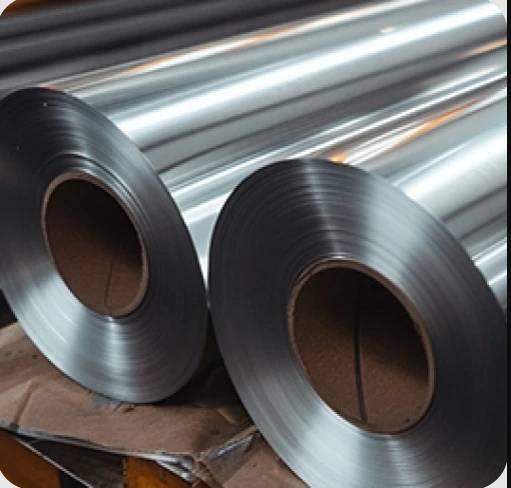

5083 Aluminum Foils

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

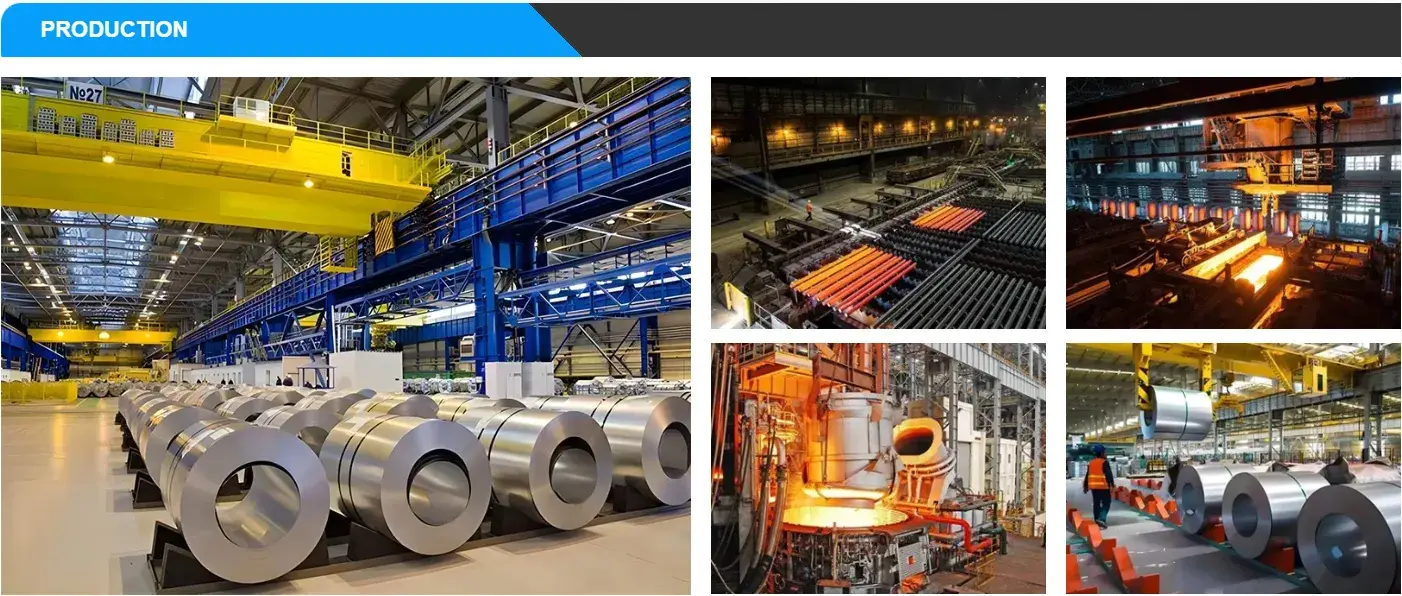

Our Factory

5083 aluminum foil is a high-performance material engineered for strength, corrosion resistance, and exceptional workability. Made from aluminum-magnesium-manganese alloy, it is ideal for harsh environments where strength and resistance to seawater or chemicals are critical.

Whether used in marine, automotive, or industrial applications, our 5083 aluminum foil delivers reliable, long-term performance.

Key Features of 5083 Aluminum Foil

-

Excellent Corrosion Resistance

Performs exceptionally well in marine and chemical settings. -

High Strength

Maintains structural integrity under mechanical stress. -

Outstanding Workability

Easy to form, bend, and weld for custom fabrication. -

Wide Range of Tempers

Available in O, H18, H19, H22, H24, H26, and H28. -

Versatile Surface Options

Comes in plain or embossed finishes.

5083 vs. 5052 Aluminum Foil: What’s the Difference?

| Feature | 5083 Aluminum Foil | 5052 Aluminum Foil |

|---|---|---|

| Main Alloying Elements | Mg & Mn | Mg |

| Tensile Strength | Higher (~317 MPa typical) | Lower (~230 MPa typical) |

| Corrosion Resistance | Excellent (especially seawater) | Very good (less resistant to seawater) |

| Weldability | Excellent | Good |

| Best Application | Marine, tankers, aerospace | Food containers, packaging |

| Price | Slightly higher | More economical |

Choose 5083 if your application demands high strength and superior corrosion resistance, especially in marine or structural settings.

Technical Specifications of 5083 Foil

| Specification | Value |

|---|---|

| Thickness (mm) | 0.01 – 0.2 |

| Width (mm) | 200 – 1600 |

| Standard | GB, JIS, DIN, ASTM |

| Surface Treatment | Plain, Embossed, Custom Finishes |

| Temper Options | O, H18, H19, H22, H24, H26, H28 |

| Packaging | Export-grade wooden box or custom |

Final Inspection Checklist: 5083 Aluminum Foil

| Task Description | Completed (✔/✘) |

|---|---|

| Confirmed end-use industry (marine, automotive, chemical) | |

| Selected the appropriate temper based on forming or strength needs | |

| Verified thickness and width specifications for fit and function | |

| Chose correct surface treatment (plain, embossed, etc.) | |

| Ensured compliance with ASTM, JIS, or relevant standard | |

| Requested test reports (chemical composition, mechanical properties) | |

| Reviewed packaging method (pallets, waterproof wrapping) | |

| Compared with alternative alloys (5052, 6061) | |

| Finalized lead time and delivery requirements |

Packing And Delivery

Luo Kaiwei Steel Company is Leading aluminum manufacturer, specializing in pre-painted coils, aluminum products (alloys 1050-7075). We offer ASTM/EN certified aluminum foil and pre-painted coils, and third-party inspected. Instant quote for bulk orders (thickness 0.2-150mm). 24-hour global shipping support.