CATEGORIES

FEATURED PRODUCTS

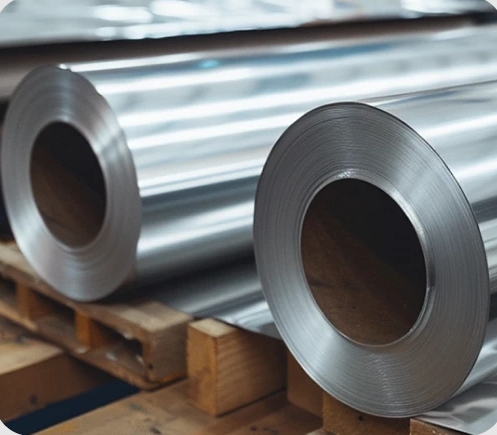

3003 Aluminum Foils

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

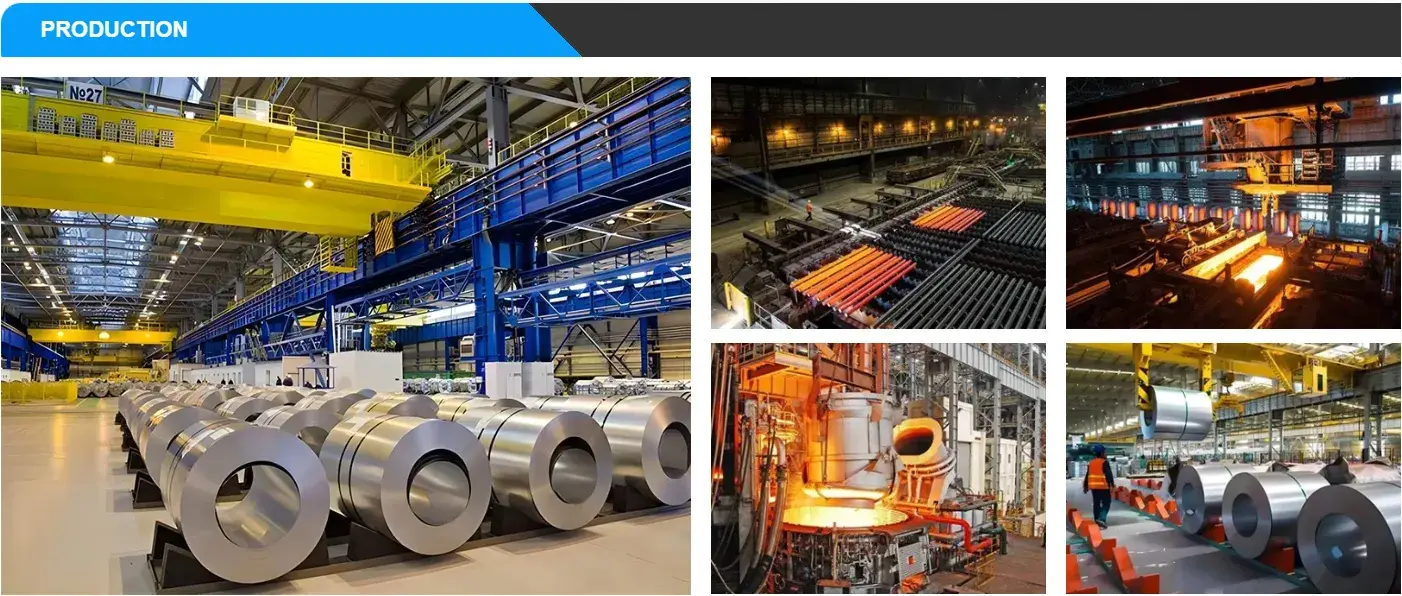

Our Factory

3003 aluminum foil is a cost-effective, non-heat-treatable alloy offering superior corrosion resistance, excellent formability, and a clean, smooth finish. With added manganese, this alloy is ideal for packaging, insulation, architectural, and industrial applications requiring both strength and aesthetics.

Key Features of 3003 Aluminum Foil

-

✅ Corrosion Resistant: Ideal for humid and chemically reactive environments.

-

✅ Excellent Workability: Easily shaped, stamped, or rolled.

-

✅ Smooth Finish: Enhances both performance and appearance.

-

✅ Weldable: Compatible with most standard welding techniques.

-

✅ Economical: Offers great performance at a lower cost than other alloys.

Comparison: 3003 Aluminum Foil vs 8011 Aluminum Foil

| Feature | 3003 Aluminum Foil | 8011 Aluminum Foil |

|---|---|---|

| Main Alloying Element | Manganese (Mn) | Iron (Fe) and Silicon (Si) |

| Corrosion Resistance | Excellent | Very good |

| Mechanical Strength | Moderate | Higher in tempers like H18 |

| Formability | Superior | Good |

| Applications | Roofing, insulation, cookware | Pharmaceutical, food packaging |

| Weldability | Good | Fair |

| Surface Finish | Polished and smooth | Available in plain or lacquered forms |

👉 Choose 3003 when flexibility, corrosion resistance, and finish matter most.

Technical Specifications

| Parameter | Specification |

|---|---|

| Thickness (mm) | 0.01 – 0.2 |

| Width (mm) | 300 – 1600 |

| Surface Treatment | Plain, Embossed, Custom options |

| Temper Grades | O, H22, H24 |

| Packaging | Export-grade wooden crates with wrapping |

| Standard Compliance | GB, JIS, DIN, ASTM |

Final Checklist for 3003 Aluminum Foil Procurement

| Task Description | Completed (✔/✘) |

|---|---|

| Confirmed foil thickness and width for application | |

| Selected temper based on forming or strength requirement | |

| Chose surface finish based on function or aesthetic need | |

| Verified compatibility with industry standard (ASTM, GB, JIS, etc.) | |

| Checked weldability for fabrication needs | |

| Compared against alternatives like 8011 or 6061 | |

| Ensured corrosion resistance for operating environment | |

| Reviewed packaging type and protection measures | |

| Requested mill certificate and quality inspection reports |

Packing And Delivery

Luo Kaiwei Steel Company is Leading aluminum manufacturer, specializing in pre-painted coils, aluminum products (alloys 1050-7075). We offer ASTM/EN certified aluminum foil and pre-painted coils, and third-party inspected. Instant quote for bulk orders (thickness 0.2-150mm). 24-hour global shipping support.