CATEGORIES

FEATURED PRODUCTS

2024 Aluminum Foil

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

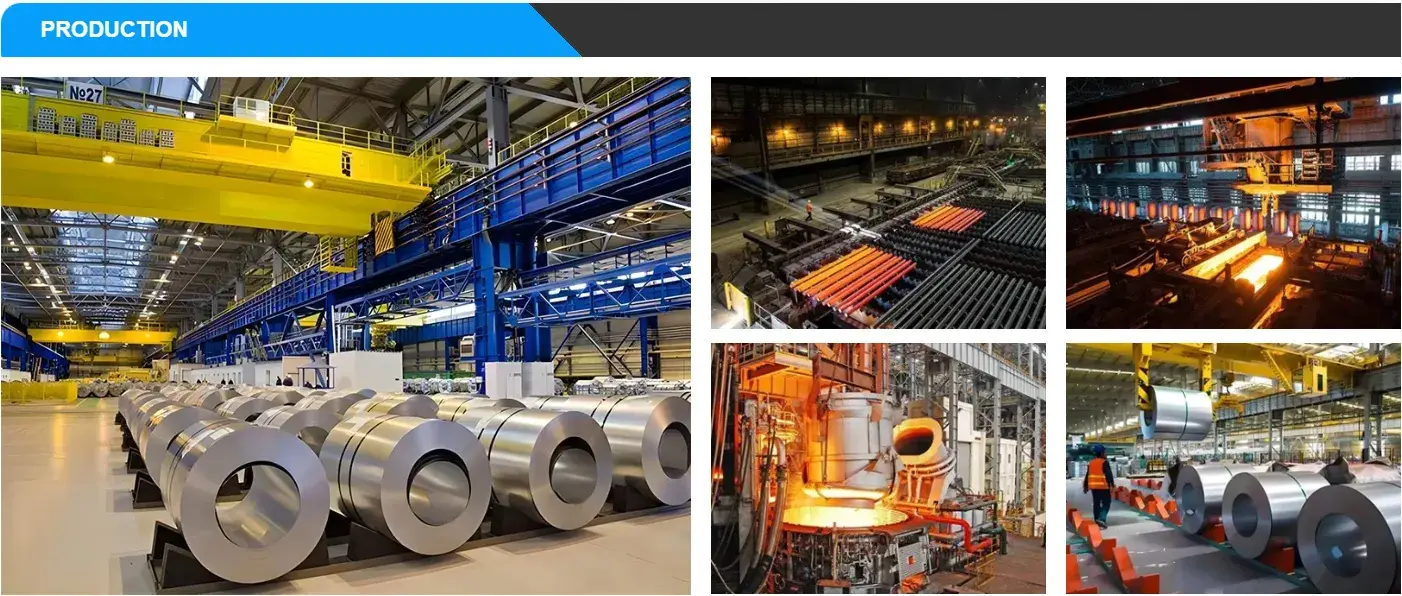

Our Factory

Unmatched Hygiene & Protection

Our food-grade aluminum foil offers superior barrier properties with 99.5% purity. The non-porous surface prevents bacterial growth, making it ideal for sensitive applications.

Key Features:

- Absolute Safety: FDA & EU compliant for direct food contact

- Complete Barrier: Blocks 100% light, oxygen, and moisture

- Temperature Resistant: Performs from -50°C to +350°C

- Odorless Protection: Won't transfer tastes or smells

Comprehensive Product Range

1. Household Foil (Alloy 8011/1235-O)

- Thickness: 9-30 microns (±3%)

- Width: 250-1400mm (customizable)

- Tensile: 60-90 MPa

- Ideal for: Food wrapping, baking, storage

2. Pharmaceutical Foil (Alloy 8011-H18)

- Thickness: 20-25 microns (±2%)

- Pinholes: <8/m²

- Break Force: ≥5N

- Applications: Blister packs, medicine protection

3. Container Foil (Alloy 3003-H24)

- Thickness: 40-120 microns

- Tensile: 110-150 MPa

- Uses: Food trays, ready-meal containers

Technical Superiority

Precision Manufacturing:

✓ Thickness tolerance: ±2% for critical applications

✓ Width accuracy: ±0.3mm

✓ Surface quality: Ra 0.6-1.0μm

Specialized Options:

- Anti-stick coatings

- Printable surfaces (40-44 dynes/cm)

- Custom embossing patterns

Performance Comparison

| Specification | Household | Pharma | Container |

|---|---|---|---|

| Thickness | 9-30μm | 20-25μm | 40-120μm |

| Tensile | 60-90 MPa | 140-180 MPa | 110-150 MPa |

| Elongation | 15-25% | 2-4% | 10-15% |

| Moisture Barrier | Excellent | Superior | Excellent |

Quality Assurance

- ISO 9001:2015 certified production

- SGS tested for heavy metals

- Halal/Kosher compliance available

- Full batch traceability system

Packaging Options:

• Jumbo rolls (OD 500-800mm)

• Slit coils (ID 76/152mm)

• Custom-cut sheets

Lead Time: 7-10 working days

Why Choose Us?

First, our advanced rolling technology ensures consistency. Second, rigorous QC guarantees flawless surfaces. Moreover, we offer specialized alloy options. Additionally, custom solutions are available. Finally, global certifications provide peace of mind.

For food packaging, select 8011-O alloy. Pharma applications require H18 temper. Regardless of requirements, our products deliver reliable performance.

Packing And Delivery

Luo Kaiwei Steel Company is Leading aluminum manufacturer, specializing in pre-painted coils, aluminum products (alloys 1050-7075). We offer ASTM/EN certified aluminum foil and pre-painted coils, and third-party inspected. Instant quote for bulk orders (thickness 0.2-150mm). 24-hour global shipping support.