CATEGORIES

FEATURED PRODUCTS

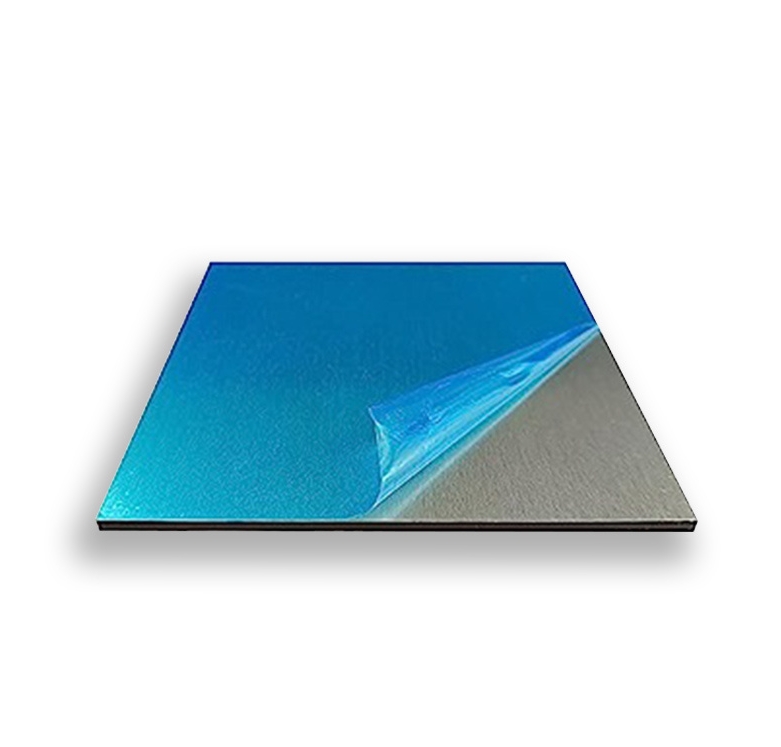

1100 Aluminum Plate

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

1100 Aluminum Plate: Ultra-Pure Commercial Grade for Forming & Food Packaging

1100 aluminum plate (UNS A91100) offers 99.0%+ aluminum purity with exceptional workability, achieving 28-40% elongation in annealed conditions. Compliant with ASTM B209 and EN 485 standards, this non-heat-treatable alloy combines 90-145 MPa tensile strength with 98% IACS conductivity. Featuring ≤0.95% Si+Fe impurities, it excels in food-grade applications while maintaining ≤0.02mm/year corrosion rates in pH 6-8 environments. Available in 0.1-120mm thickness (±0.03mm tolerance) with H18/O tempers.

Key Technical Specifications & Certifications

Mechanical Properties:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 90-145 MPa | ASTM E8/E8M |

| Yield Strength (0.2%) | 34-125 MPa | ISO 6892-1 |

| Elongation (50mm G.L.) | 15-35% | EN 10002-1 |

| Hardness (Annealed) | 23-32 HB | ASTM E10 |

Physical Properties:

| Parameter | Value | Application Impact |

|---|---|---|

| Electrical Conductivity | 59.5% IACS | Busbars with 25% cost savings vs. copper |

| Thermal Expansion | 23.6×10⁻⁶/°C | Stable in -40°C to 150°C thermal cycling |

| Anodized Thickness | 5-25μm (Type II) | Architectural panels with 10-year warranty |

Certifications: FDA CFR 21, ISO 22000 for food contact, and NSF/ANSI 51 for food equipment.

Engineering Advantages Over 3003/5052 Alloys

- Formability: Achieves 6.5mm minimum bend radius at 1mm thickness (R/t=6.5).

- Weldability: TIG welding with ER1100 filler (joint efficiency ≥92%).

- Surface Finish: Mill finish Ra 0.3-0.8μm, polishable to Ra ≤0.1μm.

- Cost Efficiency: 18-22% lower material cost vs. 3003 alloy for similar applications.

Critical Applications & Case Studies

1100 aluminum plate is specified for:

- Packaging: Beverage can tabs (0.25mm, H19) with 40N tear resistance

- Construction: Decorative trims (1.2mm, H14) achieving 85% light reflectivity

- Electronics: Capacitor housings (0.5mm, O temper)

- HVAC: Heat exchanger fins (0.15mm, H18)

Project Highlight: Coca-Cola uses 0.2mm 1100-H19 foil for bottle caps, achieving 99.97% hermetic seal rates in filling lines.

Customization & Quality Assurance

Processing Options:

- Temper States: O (soft), H12, H14, H16, H18

- Surface Treatment: Anodizing (clear/gold/black), PVDF coating

- Cutting: Slitting (±0.1mm) or CNC punching (±0.05mm)

Testing Protocols:

- Glow Discharge Spectroscopy: Verifies Cu ≤0.12%, Zn ≤0.05%

- Hydrostatic Testing: 2.5MPa pressure for food container grades

- Salt Spray Resistance: 1,000+ hours per ASTM B117

Why Choose Our 1100 Aluminum Plates?

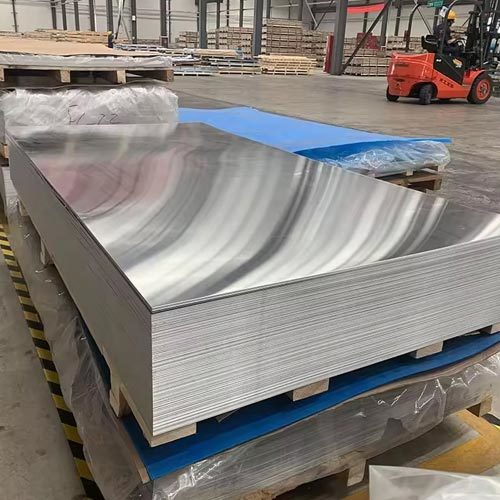

Our AS9100-certified production ensures ≤±1% thickness variation and 99.3%+ purity per EN 573-3. With 12,000-ton annual capacity, we guarantee 10-20 day lead times for stock sizes and custom annealing services.

Download our free guide comparing 1100 vs. 1050/3003 alloys. Request a food safety compliance certificate for FDA-regulated applications.

Packaging: VCI film + desiccant bags; 20ft container holds 16-20 tons.

Certificates: Mill Test Reports (MTR) with full traceability provided.

Packing And Delivery

Luo Kaiwei Steel Company is Leading aluminum manufacturer, specializing in pre-painted coils, aluminum products (alloys 1050-7075). We offer ASTM/EN certified aluminum foil and pre-painted coils, and third-party inspected. Instant quote for bulk orders (thickness 0.2-150mm). 24-hour global shipping support.