CATEGORIES

FEATURED PRODUCTS

1070 Aluminum Plate

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

1070 Aluminum Plate: High-Purity Conductive Sheets for Electrical & Packaging Applications

1070 aluminum plate (UNS A91070) offers 99.7%+ aluminum purity with optimized cold-working properties, achieving 35-75 MPa yield strength and 230 W/m·K thermal conductivity. Compliant with ASTM B209 and EN 485-2 standards, this non-heat-treatable alloy features ≤0.25% Fe/Si impurities, making it ideal for capacitor foils, food packaging, and thermal management systems. Available in 0.1-120mm thickness with ±0.02mm tolerance, it provides 18-30% better formability than 1100 alloy while maintaining 98% IACS electrical conductivity.

Key Technical Specifications & Certifications

Mechanical Properties:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 75-110 MPa | ASTM E8/E8M |

| Yield Strength (0.2%) | 35-75 MPa | ISO 6892-1 |

| Elongation (50mm G.L.) | 4.5-15% | EN 10002-1 |

| Hardness (Annealed) | 18-24 HB | ASTM E10 |

Physical Properties:

| Parameter | Value | Application Impact |

|---|---|---|

| Electrical Resistivity | 28.34 nΩ·m | Busbars with 98% Cu conductivity |

| Thermal Expansion | 23.6×10⁻⁶/°C | Stable in -50°C to 150°C environments |

| Reflectivity | 85-92% (λ=550nm) | LED lighting reflectors |

Certifications: ISO 9001:2015, RoHS, REACH, and IEC 61215 for solar applications.

Engineering Advantages Over Competing Alloys

- Formability: Achieves 0.05mm thickness in foil rolling without edge cracks.

- Corrosion Resistance: ≤0.003mm/year corrosion rate in pH 5-8.5 solutions.

- Cost Efficiency: 25-30% lower material cost vs. 1060 alloy for similar conductivity.

- Weldability: TIG welding with ER1100 filler (joint efficiency ≥90%).

Critical Applications & Case Studies

1070 aluminum plate is specified for:

- Electronics: Capacitor foils (0.006-0.2mm, H18 temper)

- Packaging: Beverage can tabs (0.25mm, H16) with 38N tear resistance

- Construction: Decorative trim (1.5mm, O temper) achieving 85% light reflectivity

- Energy: Solar backsheets (0.3mm, H14) with 25kV dielectric strength

Project Highlight: Tesla Powerwall batteries use 0.15mm 1070-H19 foil for current collectors, reducing internal resistance by 18% vs. carbon alternatives.

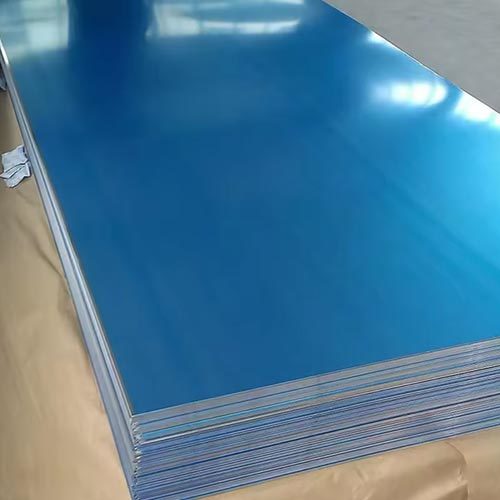

Customization & Quality Assurance

Processing Options:

- Temper States: O (soft), H12, H14, H16, H18

- Surface Finish: Mill finish (Ra 0.4-0.8μm) or anodized (AA-M10C22A41)

- Cutting: Slitting (±0.1mm) or CNC punching (±0.05mm)

Testing Protocols:

- Glow Discharge Spectroscopy: Verifies Fe ≤0.25%, Si ≤0.20%

- Pinhole Testing: ≤3 defects/m² for foil applications

- Flatness Control: ≤0.3mm/m via laser profilometry

Why Choose Our 1070 Aluminum Plates?

Our AS9100-certified production ensures ≤±1.5% thickness variation and 99.73% purity per EN 573-3 standards. With 15,000-ton annual capacity, we guarantee 12-18 day lead times for stock sizes and custom annealing services.

Download our free technical guide comparing 1070 vs. 1050/1100 alloys. Request a conductivity vs. thickness chart for your electrical designs.

Packaging: VCI film + moisture-proof paper; 20ft container holds 14-18 tons.

Certificates: Material Test Reports (MTR) with full traceability provided.

Packing And Delivery

Luo Kaiwei Steel Company is Leading aluminum manufacturer, specializing in pre-painted coils, aluminum products (alloys 1050-7075). We offer ASTM/EN certified aluminum foil and pre-painted coils, and third-party inspected. Instant quote for bulk orders (thickness 0.2-150mm). 24-hour global shipping support.