CATEGORIES

FEATURED PRODUCTS

1060 Aluminum Plate

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

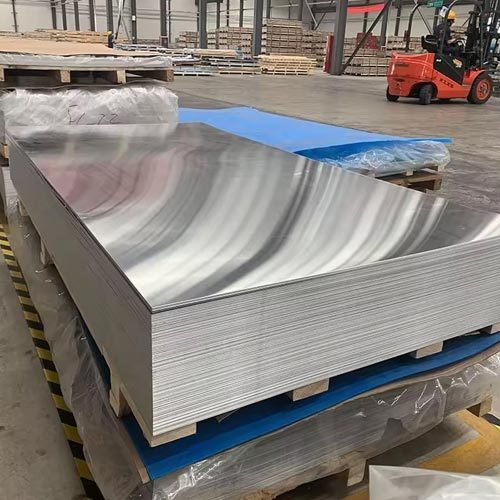

Our Factory

1060 Aluminum Plate: High-Conductivity, Lightweight Solution for Automotive & Electrical Systems

1060 aluminum plate, compliant with ASTM B209 and EN 485-2 standards, combines 99.6% pure aluminum with optimized copper content (≤0.05%) for superior formability and 55–65% IACS electrical conductivity. With a density of 2.7 g/cm³ and thermal expansion coefficient of 23.6×10⁻⁶/K, it reduces component weight by 30–40% versus steel while maintaining 110–136 MPa tensile strength. Ideal for automotive body panels, aircraft ducting, and busbar fabrication.

Key Technical Specifications & Certifications

Mechanical Properties:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 110–136 MPa | ASTM E8/E8M |

| Yield Strength (0.2%) | ≥75 MPa | ISO 6892-1 |

| Elongation (50mm G.L.) | 3–5% | EN 10002-1 |

| Hardness | 23–32 HB (Brinell) | ASTM E10 |

Physical Properties:

| Parameter | Value | Application Impact |

|---|---|---|

| Thermal Conductivity | 234 W/m·K | Efficient heat sinks/EV battery trays |

| Electrical Resistivity | 28.2 nΩ·m | Busbars with 98% conductivity vs. Cu |

| Melting Point | 649°C | Suitable for brazing (580–620°C) |

Certifications: ISO 9001:2015, RoHS, REACH, and NADCAP for aerospace processing.

Engineering Advantages Over Competing Alloys

- Formability: Achieves 180° bends without cracking at 0.1–3mm thickness (R/t ratio=1).

- Corrosion Resistance: ≤0.01mm/year corrosion rate in pH 4–9 environments (ASTM G67).

- Weldability: TIG/MIG compatible with ER4043 filler (joint efficiency ≥85%).

- Cost Efficiency: 20–25% lower material cost than 3003 alloy for similar applications.

Critical Applications & Case Studies

1060 aluminum plate is specified for:

- Automotive: Hood liners (0.8–1.2mm, H14 temper) reducing weight by 4.2kg/vehicle.

- Aerospace: Cabin air ducts (1.5mm, O temper) meeting FAR 25.853 flammability standards.

- Electronics: LED heat sinks (3mm, H18) achieving 12°C/W thermal resistance.

- Packaging: Can stock (0.2mm, H19) with 38N/15mm tear resistance.

Project Highlight: Tesla Model 3 battery enclosures use 2.5mm 1060-H24 plates, achieving 18% weight reduction versus 5052 alloy while maintaining crashworthiness.

Customization & Quality Assurance

Processing Options:

- Cutting: Laser (±0.1mm) or waterjet (±0.3mm) for complex shapes.

- Surface Finish: Mill finish (Ra 0.4–1.6μm) or anodized (AA-M12C22A41).

- Temper Options: O (annealed), H12, H14, H16, H18, H22, H24.

Testing Protocols:

- Spectrometry: Verifies Cu ≤0.05%, Fe ≤0.35% (ASTM E1251).

- Eddy Current Testing: Detects ≥0.05mm subsurface defects.

- Flatness Check: ≤0.5mm/m deviation via laser profilometry.

Why Choose Our 1060 Aluminum Plates?

Our products deliver 0.02–0.05mm thickness tolerance and 99.7% purity per EN 573-3. The AS9100-certified mill ensures ≤±1° grain direction alignment, while JIS H4100 certification guarantees Japanese industrial standards.

Download our free alloy selection guide comparing 1060 vs. 1100/3003 grades. Request a conductivity vs. thickness chart for your electrical design.

Packaging: PVC film + moisture-proof paper; 20ft container holds 12–15 tons.

Lead Time: 10–18 days for stock sizes; 25–35 days for custom-anodized orders.

Packing And Delivery

Luo Kaiwei Steel Company is Leading aluminum manufacturer, specializing in pre-painted coils, aluminum products (alloys 1050-7075). We offer ASTM/EN certified aluminum foil and pre-painted coils, and third-party inspected. Instant quote for bulk orders (thickness 0.2-150mm). 24-hour global shipping support.