CATAGÓIRÍ

TÁIRGÍ RÁTHAÍOCHTA

Color Coated Galvalume Steel Coil PPGL

Short Description:

PPGL (Pre-Painted Galvalume) Steel Coils combine a 55% aluminum-zinc alloy base with UV-resistant polymer coatings, delivering 2–4x longer lifespan vs. standard galvanized steel (PPGI). Designed for extreme climates (-40°C to 120°C), these coils achieve ASTM B117 1,500h salt spray resistance and 85% solar reflectance (Cool Roof Rating Council certified). With RAL 9006–RAL 9023 color options and PVDF coatings (70% fluoropolymer resin), PPGL is the go-to material for energy-efficient roofing, industrial cladding, and architectural façades.

Color Coated Galvalume Steel Coil PPGL Product Overview

PPGL (Pre-Painted Galvalume) Steel Coils combine a 55% aluminum-zinc alloy base with UV-resistant polymer coatings, delivering 2–4x longer lifespan vs. standard galvanized steel (PPGI). Designed for extreme climates (-40°C to 120°C), these coils achieve ASTM B117 1,500h salt spray resistance and 85% solar reflectance (Cool Roof Rating Council certified). With RAL 9006–RAL 9023 color options and PVDF coatings (70% fluoropolymer resin), PPGL is the go-to material for energy-efficient roofing, industrial cladding, and architectural façades.

Key Technical Specifications

1. Dimensional & Material Properties

| Parameter | Specifications | |

|---|---|---|

| Base Metal | Galvalume (55% Al, 43.4% Zn, 1.6% Si) | AZ150–AZ200 Coating Weight |

| Thickness | 0.13 mm (ultra-thin) – 0.8 mm (heavy-duty) | ±0.02 mm Tolerance |

| Width | 600 mm – 1,250 mm (slit-to-size) | Coil Weight: 3–15 tons (ID: 508/610 mm) |

| Surface Finish | Embossed/Stucco (0.3–0.7mm profile) | Smooth (Ra ≤0.5µm) |

2. Coating System

| Layer | Coating Type | Thickness | Key Performance |

|---|---|---|---|

| Topcoat | PVDF/HDP/SMP/PE | 15–30 µm | 20+ years color retention (ISO 11507) |

| Primer | Epoxy (5–10 µm) | 5–25 µm | Adhesion: Class 0 (ISO 2409 cross-cut) |

| Backing Coat | Polyester/Acrylic | 5–15 µm | Anti-fingerprint, scratch resistance |

Coating Comparison & Applications

| Type | Resin Content | Salt Spray Resistance | Best For |

|---|---|---|---|

| PVDF | 70% Kynar 500 | 2,000h+ (ASTM B117) | Coastal roofs, chemical plants |

| HDP | High-Durability Polyester | 1,500h | Solar farms, warehouse façades |

| SMP | Silicone-Modified | 1,000h | Residential roofing, HVAC ducts |

| PE | Standard Polyester | 800h | Indoor partitions, furniture |

Performance Advantages

- Corrosion Resistance: 55% Al-Zn layer outperforms PPGI by 3x in humid environments.

- Thermal Efficiency: 85% reflectivity reduces rooftop temps by 15°C (ASHRAE 90.1 compliant).

- Formability: 0.4T bend radius (0.3mm thickness) suits roll-forming/press-braking.

- Fire Safety: Class A fire rating (ASTM E84) with ≤5 smoke density.

- Eco-Friendly: 30% recycled content + RoHS-compliant coatings.

Industry Applications

| Sector | Use Case | Recommended Coating |

|---|---|---|

| Construction | Airport terminal roofs | PVDF (RAL 9006) |

| Transportation | EV charging station canopies | HDP (RAL 7035) |

| Renewable Energy | Solar panel backing sheets | SMP (RAL 1015) |

| Furniture | Outdoor café tables | PE (RAL 5021) |

Certifications & Standards

- Quality: ISO 9001, ASTM A792 (Galvalume)

- Sustainability: LEED v4.1 MR Credit 4 (30% recycled content)

- Safety: EN 13501-1 (Fire Class A2-s1, d0)

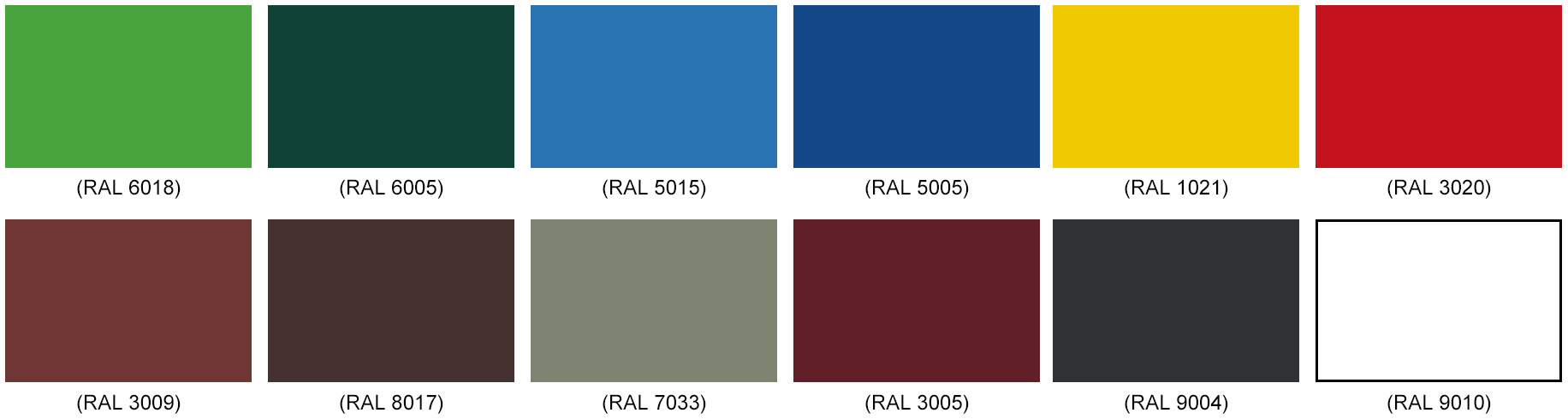

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

Packing And Delivery

Fág Do Theachtaireacht