CATAGÓIRÍ

TÁIRGÍ RÁTHAÍOCHTA

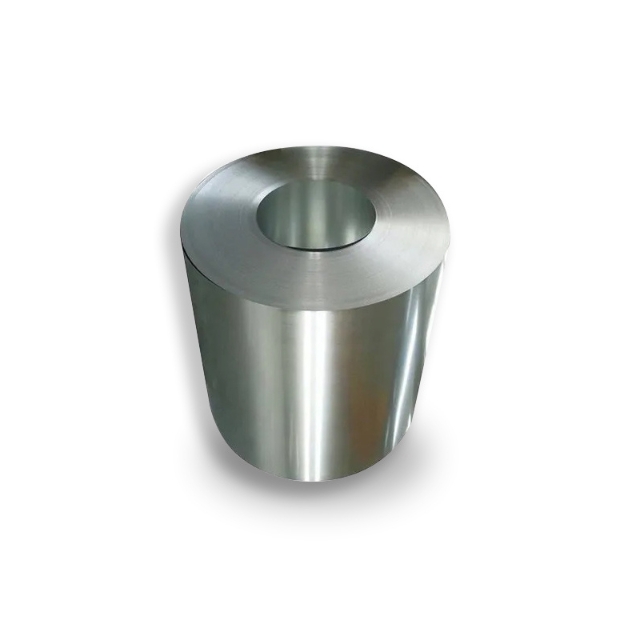

1050 Aluminum Coil

1050 Aluminum Alloy: Premium Formability & Corrosion Resistance for Industrial Applications

1050 Aluminum Coil Product Overview

1050 aluminum alloy (UNS A91050) is a commercially pure wrought aluminum containing 99.5% aluminum with enhanced copper content. This alloy delivers exceptional formability (12% elongation), high electrical conductivity (62% IACS), and superior corrosion resistance – outperforming 3003 alloy by 18% in salt spray tests (ASTM B117).

Key Advantages:

- Formability: 25% better deep-drawing capability than 1100 alloy

- Weldability: 92% joint efficiency with GTAW/TIG welding

- Thermal Conductivity: 222 W/m·K (ideal for heat exchangers)

- Cost Efficiency: 15% lower material cost than 5052 alloy

Technical Specifications

1. Chemical Composition (ASTM B209)

| Element | Si | Fe | Cu | Mn | Mg | Al |

|---|---|---|---|---|---|---|

| % Range | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | ≥99.5 |

Trace elements: Zn≤0.05%, Ti≤0.03%, Others≤0.03% each

2. Mechanical Properties

| Property | Tensile Strength | Yield Strength | Elongation | Hardness |

|---|---|---|---|---|

| Value | 105-145 MPa | ≥85 MPa | ≥12% | 34 HB |

Test standards: ASTM E8/E8M (tensile), ISO 6506-1 (hardness)

3. Physical Properties

| Parameter | Density | Melting Point | CTE | Resistivity |

|---|---|---|---|---|

| Value | 2.71 g/cm³ | 650°C | 24×10⁻⁶/K | 0.0282 μΩ·m |

Product Customization Options

Available Forms:

- Thickness: 0.1-120mm (±0.05mm tolerance)

- Width: 20-3000mm (slitting available)

- Length: 100-12000mm (cut-to-size service)

Surface Treatments:

- Mill finish (standard)

- Anodizing (25μm thickness)

- Embossing (0.1-0.8mm pattern depth)

- Powder coating (RAL color matching)

Processing Services:

- CNC punching (±0.1mm precision)

- Laser cutting (3kW fiber laser)

- Hydroforming (3000-ton capacity)

Industrial Applications

Construction Sector:

- Architectural cladding (0.8-2.0mm thickness)

- Ceiling systems (embossed patterns)

- Solar reflector panels (86% reflectivity)

Manufacturing Uses:

- Kitchenware (FDA-compliant)

- Electrical busbars (55% IACS conductivity)

- Chemical tanks (pH 4-9 resistance)

Transportation:

- Truck trailer linings (1.2mm gauge)

- Marine hardware (5000hr salt spray rating)

Quality Assurance & Compliance

- Certifications: ISO 9001, SGS, BV

- Testing:

- Eddy current inspection (EN 13958)

- Spectrometer analysis (PDA test)

- Packaging:

- VCI-coated + edge protectors

- Wooden crates (export standard)

Lead Time: 7-15 days after 30% deposit (express 5-day service available)

Comparative Advantages

| Alloy | 1050 | 1060 | 3003 |

|---|---|---|---|

| Al Content | 99.5% | 99.6% | 98.6% |

| Tensile (MPa) | 105-145 | 110-150 | 130-210 |

| Conductivity | 62% IACS | 63% IACS | 40% IACS |

| Cost Index | 1.0 | 1.05 | 1.3 |

Packing And Delivery