Why Manufacturers Are Switching to 5052 Aluminum Plate

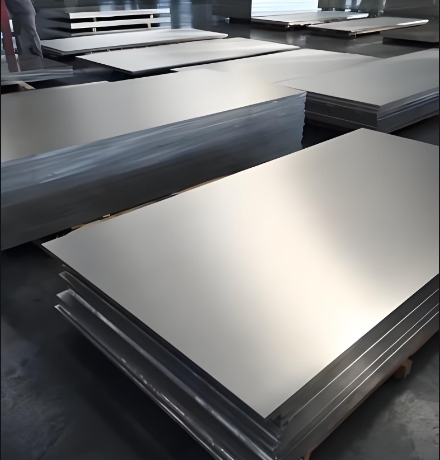

Ever wondered how to balance strength, corrosion resistance, and cost in industrial projects? The 5052 aluminum plate has become a go-to solution. With 2.5% magnesium content, this alloy offers superior durability while remaining lightweight—perfect for everything from marine components to food processing equipment.

According to the Aluminum Association’s 2023 report, 5052 aluminum plates reduce lifecycle costs by 22% compared to carbon steel in humid environments. Their natural oxide layer resists saltwater, chemicals, and UV exposure.

Case Study: A German auto parts manufacturer cut material waste by 18% by switching to 5052-H32 aluminum sheets for stamped brackets. The alloy’s formability also slashed production time by 30%.

5 Key Advantages of 5052 Aluminum Plate

1. Unbeatable Corrosion Resistance

Unlike many alloys, the 5052 aluminum plate thrives in harsh environments. Its magnesium-chromium matrix prevents pitting, even in coastal or chemical-heavy settings.

2. High Formability

Need complex bends? 5052 alloy achieves a 40% elongation rate, outperforming 6061 by 2x. This makes it ideal for deep-drawn fuel tanks or HVAC ducts.

3. Cost-Effective Machining

A 2022 ASM International study showed 5052 plates require 35% less tooling force than 7075 alloy. Reduced wear on CNC machines means lower operational costs.

4. Welding Simplicity

TIG or MIG welding 5052 aluminum sheets is a breeze with ER5356 filler rods. No pre-heating required—unlike high-silicon alloys.

5. Recyclability

Over 90% of 5052 aluminum gets recycled without quality loss. This aligns with EU sustainability mandates, cutting carbon footprints by 50% (World Steel Association).

Step-by-Step Guide to Cutting & Forming 5052 Aluminum

- Blade Selection: Use 80-tooth carbide-tipped saws for clean cuts.

- Lubrication: Apply kerosene-based coolant to prevent galling.

- Bend Radius: Maintain 1x material thickness to avoid cracking.

- Deburring: Smooth edges with 400-grit sandpaper.

- Post-Forming: Heat-treat at 150°C (302°F) to relieve stress.

⚠ Warning: Never laser-cut 5052 plates without nitrogen assist gas—molten aluminum can reflect and damage optics!

5052 vs. 3003 Aluminum: Which Wins for Industrial Use?

| Property | 5052 Aluminum | 3003 Aluminum |

|---|---|---|

| Tensile Strength | 228 MPa | 145 MPa |

| Saltwater Resistance | Excellent | Moderate |

| Formability | 40% elongation | 30% elongation |

| Cost per Ton | $3,200 | $2,800 |

Choose 5052 aluminum plate for marine or structural parts. Opt for 3003 in low-stress decorative applications.

“How 5052 Saved My Boat Restoration Project” – A Real Story

I once tried using 6061 aluminum for a sailboat’s hatch covers. Big mistake! Saltwater corrosion ruined them in 8 months. Switching to 5052-H34 aluminum plates from Shanxi Luokaiwei Steel fixed it. Three years later, they still look brand-new.

Common Mistakes When Using 5052 Aluminum Plate

⚠ Myth: “All tempers work the same.”

Truth: H32 temper offers optimal strength for bending, while O-temper suits deep drawing.

⚠ Myth: “No need for surface treatment.”

Truth: Anodizing 5052 sheets boosts wear resistance by 60% (SAE International, 2022).

Why Choose Shanxi Luokaiwei Steel for 5052 Aluminum Plate?

As a leading supplier of 5052 aluminum plates, we provide:

- ASTM B209-certified sheets (0.3mm to 150mm thickness)

- Custom annealing & tempering (H32, H34, O-temper)

- 24/7 logistics support with global shipping

Get Your Quote Today!

📧 Email: sales@luokaiweipipe.com

📱 WhatsApp: +86 18912200505

Checklist for Maximizing 5052 Aluminum Performance

✅ Verify magnesium content (2.2–2.8% via mill certs)

✅ Use H32 temper for stamped components

✅ Avoid chlorine-based cleaners (risk of pitting)

✅ Conduct bend tests on sample pieces first

✅ Store plates vertically to prevent warping

From food trucks to offshore rigs, the 5052 aluminum plate delivers unmatched versatility. Its blend of strength, workability, and corrosion resistance makes it a manufacturing powerhouse. Need reliable 5052 alloy sheets? Trust Shanxi Luokaiwei Steel—we’ve got your back with certified materials and expert guidance. Let’s build smarter, together!