KATEGORIAK

PRODUKTU NAGUSIAK

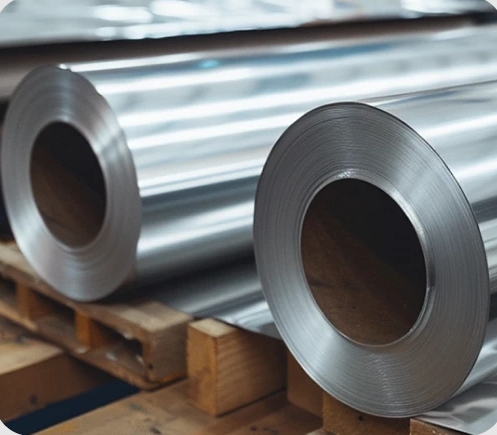

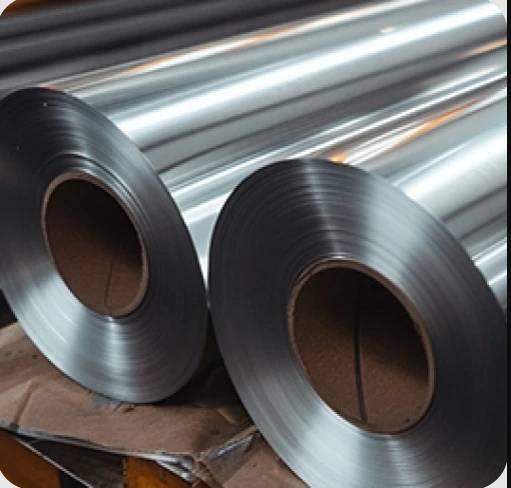

3003 Aluminum Foils

deskribapen laburra:

3003 aluminum foil is a cost-effective, non-heat-treatable alloy offering superior corrosion resistance, excellent formability, and a clean, smooth finish. With added manganese, this alloy is ideal for packaging, insulation, architectural, and industrial applications requiring both strength and aesthetics.

3003 aluminum foil is a cost-effective, non-heat-treatable alloy offering superior corrosion resistance, excellent formability, and a clean, smooth finish. With added manganese, this alloy is ideal for packaging, insulation, architectural, and industrial applications requiring both strength and aesthetics.

🔍 Key Features of 3003 Aluminiozko papera

-

✅ Corrosion Resistant: Ideal for humid and chemically reactive environments.

-

✅ Excellent Workability: Easily shaped, stamped, or rolled.

-

✅ Smooth Finish: Enhances both performance and appearance.

-

✅ Weldable: Compatible with most standard welding techniques.

-

✅ Economical: Offers great performance at a lower cost than other alloys.

🆚 Comparison: 3003 Aluminum Foil vs 8011 Aluminiozko papera

| Bereizgarri | 3003 Aluminiozko papera | 8011 Aluminiozko papera |

|---|---|---|

| Main Alloying Element | Manganese (Etsa) | Iron (Fe) and Silicon (Eta) |

| Korrosioarekiko erresistentzia | Excellent | Very good |

| Mechanical Strength | Neurritsu | Higher in tempers like H18 |

| Formability | Superior | On |

| Applications | Teala, insulation, sekulma | Pharmaceutical, food packaging |

| Weldability | On | Fair |

| Surface Finish | Polished and smooth | Available in plain or lacquered forms |

👉 Choose 3003 when flexibility, Korrosioarekiko erresistentzia, and finish matter most.

📐 Technical Specifications

| Parameter | Specification |

|---|---|

| Thickness (mm) | 0.01 – 0.2 |

| Width (mm) | 300 – 1600 |

| Surface Treatment | Plain, Embossed, Custom options |

| Temper Grades | O, H22, H24 |

| Ontziagailu | Export-grade wooden crates with wrapping |

| Standard Compliance | Gm, JIS, -Tik, Am m |

✅ Final Checklist for 3003 Aluminum Foil Procurement

| Task Description | Completed (✔/✘) |

|---|---|

| Confirmed foil thickness and width for application | |

| Selected temper based on forming or strength requirement | |

| Chose surface finish based on function or aesthetic need | |

| Verified compatibility with industry standard (Am m, Gm, JIS, etc.) | |

| Checked weldability for fabrication needs | |

| Compared against alternatives like 8011 or 6061 | |

| Ensured corrosion resistance for operating environment | |

| Reviewed packaging type and protection measures | |

| Requested mill certificate and quality inspection reports |

Utzi zure mezua