Introduction: The Role of Color Coated PPGI Steel Coils in Modern Construction

Color coated PPGI (Pre-Painted Galvanized Iron) steel coils are essential materials in modern construction, offering a perfect blend of durability, aesthetics, and cost-efficiency. These coils are used for a variety of applications, including roofing, cladding, and manufacturing. The price of PPGI steel coils can vary depending on several factors, including the type of coating applied, such as PVDF (Polyvinylidene Fluoride) or PE (Polyester) coatings.

In this article, we’ll break down the PPGI steel coil price and explore the cost differences between PVDF eta PE coatings. We’ll also highlight the factors that influence the price and guide you on how to choose the right option for your project.

What is PPGI Steel Coil?

Key Features and Benefits of PPGI Steel Coils

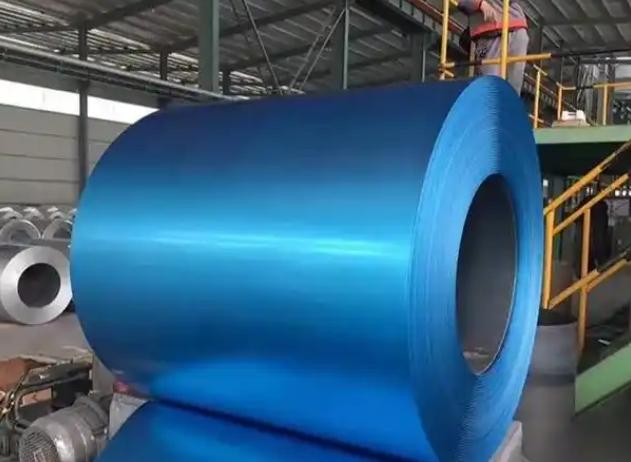

A PPGI steel coil is a sheet of galvanized steel coated with a layer of color and a protective coating. The process involves first applying a zinc coating to the steel for corrosion resistance, then applying a colored polyester or fluoropolymer coating for aesthetic appeal and additional protection. PPGI steel coils are popular for both their functional and visual properties.

PPGI steel coils come in a variety of finishes and coatings, but the most common coatings are PE (Polyester) eta PVDF (Polyvinylidene Fluoride). Each type of coating offers different benefits, influencing both the price and longevity of the product.

Factors Affecting PPGI Steel Coil Price

1. Coating Type

The type of coating on PPGI steel coils plays a significant role in determining the price. PE coatings are the most common and cost-effective option for general use, whereas PVDF coatings offer superior durability and are priced higher. The cost of the coating reflects the added protection, longevity, and aesthetics it provides.

-

PE Coating: Affordable, provides good protection, suitable for most applications like roofing and cladding.

-

PVDF Coating: Premium option, provides high UV resistance and excellent durability, ideal for harsh climates or long-lasting structures.

2. Thickness of the Steel

Thicker steel coils require more material and are generally more expensive. When purchasing PPGI steel coils, be sure to choose the right thickness based on the intended application. For example, roofing sheets might require thicker coils for added durability.

PVDF vs PE Coating Costs: A Comparison

1. Durability and Weather Resistance

-

PE Coating: Typically offers a service life of 10 to 15 years in normal environments. It provides a protective barrier against UV rays, but over time, it may show signs of wear such as fading or chalking.

-

PVDF Coating: Has a service life of up to 30 years or more. The PVDF coating is highly resistant to UV radiation, fading, and chalking, making it an ideal choice for areas with extreme weather conditions or where long-term performance is required.

Price Comparison:

| Coating Type | Estimated Price per Ton ($) | Service Life (Years) | Applications |

|---|---|---|---|

| PE Coating | 900 – 1,100 | 10 – 15 | General construction, roofs |

| PVDF Coating | 1,200 – 1,500 | 25 – 30 | High-end applications, harsh environments |

Analysis:

-

PE coatings are significantly more affordable and provide adequate performance for general construction needs.

-

PVDF coatings come at a higher price but offer superior durability, particularly for projects that require long-term performance and minimal maintenance.

Why PVDF Coatings Are Worth the Investment for Certain Projects

1. Longevity and Durability

If your project is located in an area with extreme weather conditions or requires a long-lasting material, PVDF-coated PPGI steel coils may be the best option. These coils are resistant to UV rays, pollution, and harsh climates, ensuring that your structure remains intact and visually appealing for decades.

For example, buildings in coastal areas exposed to saltwater require highly durable materials. PVDF coatings provide superior corrosion resistance and ensure the steel remains protected even in harsh coastal environments.

2. Aesthetic Appeal

PVDF coatings are available in a wide range of vibrant, long-lasting colors, and the finish typically remains glossy for much longer than PE coatings. This makes PVDF-coated PPGI steel coils ideal for high-end applications such as architectural facades, luxury buildings, or structures where aesthetics are critical.

How to Choose the Right Coating for Your Project

1. Evaluate the Environment

The first step in selecting the right coating is to assess the environmental conditions. If the structure will be exposed to extreme weather conditions, such as high humidity, saltwater, or UV rays, then PVDF coatings are worth the investment. However, for less demanding environments, PE coatings offer an excellent balance of cost and performance.

2. Consider Longevity and Maintenance

If you’re looking for a low-maintenance solution, PVDF coatings are the better choice due to their longer lifespan and superior protection against fading and wear. While PE coatings are more affordable, they may require more frequent maintenance and repainting over time.

3. Budget Constraints

For projects with strict budget constraints, PE-coated PPGI steel coils are a cost-effective option that still provides good performance. For higher-end projects where durability and aesthetics are paramount, the investment in PVDF-coated coils will provide long-term value.

Real-Life Example: Choosing Between PVDF and PE for a Residential Roofing Project

Case Study: Residential Roofing with PE Coating

In one of my recent projects, we were tasked with installing a roofing system for a residential home in a moderate climate. The homeowner’s primary concern was cost, so we opted for PE-coated PPGI steel coils. The material performed well and provided good protection against the elements. While it wasn’t as long-lasting as PVDF-coated steel, it suited the budget and climate needs of the project perfectly.

-

Outcome: The roofing system has been functional for 7 years with minimal wear, proving that PE coatings are adequate for residential applications where extreme weather isn’t a major concern.

Common Misconceptions About PPGI Steel Coatings

⚠️ Misconception 1: “PE coatings are always the cheaper option.”

Fact: While PE coatings are more affordable than PVDF coatings, the initial cost is just one part of the equation. Over time, PVDF coatings often provide better value due to their longevity and low maintenance needs.

⚠️ Misconception 2: “All coatings are the same, so it doesn’t matter which one I choose.”

Fact: The type of coating significantly affects the material’s performance. PVDF coatings are much more durable, especially in harsh environments, while PE coatings are suitable for general applications. Choosing the right coating depends on the project’s location, expected lifespan, and budget.

Step-by-Step Guide: How to Choose the Best PPGI Steel Coil for Your Project

-

Assess Environmental Conditions: Consider factors like UV exposure, humidity, and saltwater if the structure will be outdoors.

-

Determine the Required Lifespan: Think about how long you want the steel coils to last. If you need something long-lasting, consider PVDF coatings.

-

Review Your Budget: Determine how much you’re willing to spend. PE coatings are more affordable, but PVDF coatings offer superior long-term value.

-

Get Multiple Quotes: Request quotes from several suppliers and compare prices for PE eta PVDF-coated coils.

-

Confirm Delivery Times: Ensure the supplier can deliver the coils on time to avoid project delays.

Conclusion: Maximizing Value with the Right PPGI Steel Coil Coating

Choosing between PE-coated eta PVDF-coated PPGI steel coils ultimately depends on your project’s specific needs. While PE coatings are ideal for cost-effective solutions with moderate durability, PVDF coatings are worth the investment for high-end applications requiring long-term performance and minimal maintenance.

Practical Checklist for Purchasing PPGI Steel Coils

-

Assess the environmental conditions for your project (UV, humidity, etc.).

-

Determine the required lifespan for your materials.

-

Compare prices for PE eta PVDF-coated coils.

-

Request samples to evaluate coating quality.

-

Confirm delivery schedules to ensure timely project completion.

For high-quality PPGI steel coils with expert advice on coatings, contact Shanxi Luokaiwei Steel Company:

-

Posta elektronikoa: sales@luokaiweipipe.com

-

WhatsApp: +86 18912200505