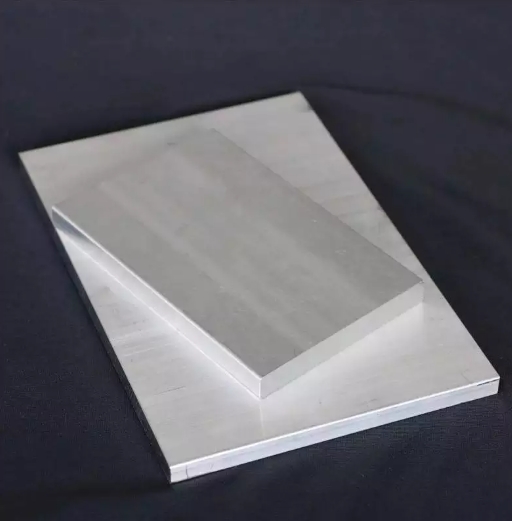

When it comes to marine applications, the choice of materials is critical for ensuring both performance and longevity. Among the various options available, the 5052 aluminum plate stands out as one of the most reliable materials for marine environments. Known for its outstanding corrosion resistance, strength, and formability, the 5052 aluminum plate is a top choice for various marine applications. In this article, we will delve deep into the reasons why the 5052 aluminum plate is preferred for marine use, comparing its advantages with other materials and offering practical insights for selecting the right alloy.

🌊 1. What Makes 5052 Aluminum Plate Ideal for Marine Environments?

Marine applications demand materials that can withstand harsh conditions, including saltwater exposure, high humidity, and constant environmental stress. The 5052 aluminum plate is specifically designed to excel in these conditions. Let’s break down the key properties that make it ideal for marine use:

-

Corrosion Resistance: The 5052 aluminum plate boasts exceptional resistance to corrosion, especially in saltwater environments. This is thanks to its high content of magnesium (2.5-2.8%), which enhances its resistance to both saltwater and atmospheric conditions.

-

Strength: With a yield strength of around 193 MPa and an ultimate tensile strength of approximately 290 MPa, the 5052 aluminum plate offers a good balance of strength and flexibility, making it perfect for applications that require durability without excessive weight.

In comparison to other aluminum alloys, such as 6061 aluminum plate, the 5052 offers better resistance to pitting and stress corrosion cracking, which are common concerns in the marine industry.

⚒️ 2. Key Benefits of 5052 Aluminum Plate in Marine Applications

The 5052 aluminum plate stands out for several reasons. Its corrosion resistance is one of the most important characteristics, but there are many other features that make it perfect for use in the marine industry.

Advantages of 5052 Aluminum Plate:

-

Superior Corrosion Resistance: Saltwater environments are tough on materials, but 5052 aluminum performs exceptionally well. According to a 2020 study on marine alloys, 5052 aluminum showed minimal degradation after 2000 hours of exposure to saltwater (Source: Journal of Materials Science).

-

Good Weldability: 5052 aluminum plate is known for its excellent weldability, especially in marine applications where seams and joints need to be both strong and leak-proof.

-

Formability: The alloy’s excellent formability allows it to be easily molded into different shapes and sizes, making it ideal for complex marine structures.

🌟 3. Common Marine Applications of 5052 Aluminum Plate

The 5052 aluminum plate is used extensively across the marine industry due to its properties. Let’s explore some of the most common applications:

-

Boat Hulls: The 5052 aluminum plate is widely used in the construction of boat hulls. Its resistance to seawater and its lightweight nature makes it a great choice for this application.

-

Marine Tanks and Storage: The alloy’s excellent corrosion resistance is especially useful for building tanks, fuel tanks, and other storage systems exposed to marine environments.

-

Marine Equipment: Other equipment like boat decks, handrails, and marine frames also benefit from the strength and durability of 5052 aluminum.

⚠️ 4. Common Misconceptions About 5052 Aluminum Plate

While the 5052 aluminum plate is a great material for marine applications, there are a few common misconceptions about its use that can lead to poor decision-making. Let’s clear these up:

-

Misconception #1: “5052 aluminum plate is the best choice for all marine applications.”

-

Reality: While 5052 aluminum excels in many areas, it may not be the best choice for every situation. For example, for extremely high-strength applications, 5083 aluminum plate might be a better choice.

-

-

Misconception #2: “5052 aluminum plate is completely immune to corrosion.”

-

Reality: While 5052 aluminum is highly resistant to corrosion, it is not entirely immune. In certain highly aggressive environments, such as those involving high acidity or alkaline conditions, its corrosion resistance may not be sufficient.

-

📝 5. How to Choose the Right 5052 Aluminum Plate for Your Marine Project

Choosing the right 5052 aluminum plate for your project involves understanding your specific needs and the conditions your material will face. Here’s a simple step-by-step guide to help you select the right alloy:

Step 1: Determine Environmental Conditions

-

Assess the marine environment where the material will be exposed. Consider factors such as saltwater exposure, humidity, and potential pollutants.

Step 2: Evaluate Strength Requirements

-

Determine the strength needed for your application. For lightweight, medium-strength applications, 5052 aluminum plate will likely meet your needs.

Step 3: Consider Fabrication Needs

-

Review your fabrication needs. If your application requires welding or forming, 5052 aluminum is an excellent choice due to its superior weldability and formability.

Step 4: Thickness and Size

-

Choose the appropriate thickness and size based on the structural requirements of your design.

Step 5: Budget and Cost Analysis

-

Consider the cost-effectiveness of 5052 aluminum plate compared to other materials like 5083 aluminum or steel.

📊 6. Comparing 5052 Aluminum Plate to Other Marine Alloys

Let’s compare 5052 aluminum plate to other popular marine alloys like 5083 aluminum plate. This comparison will help you understand the pros and cons of each material.

| Property | 5052 Aluminum Plate | 5083 Aluminum Plate |

|---|---|---|

| Corrosion Resistance | Excellent | Superior |

| Strength (MPa) | 193 | 250 |

| Weldability | Excellent | Good |

| Cost | Lower | Higher |

| Weight (g/cm³) | 2.68 | 2.66 |

While 5052 aluminum is more cost-effective and still highly resistant to corrosion, 5083 aluminum is stronger and more resistant to extreme marine conditions, though it comes at a higher cost.

✅ Practical Checklist for Using 5052 Aluminum Plate in Marine Applications

Before using 5052 aluminum plate for your marine project, here’s a checklist to ensure you’re making the right decision:

-

Corrosion Resistance: Make sure that 5052 aluminum is suitable for the environmental conditions of your application.

-

Strength Needs: Confirm that the material’s strength is sufficient for your project requirements.

-

Fabrication Requirements: Ensure that your project involves processes like welding or forming that are compatible with 5052 aluminum.

-

Application Size: Choose the appropriate thickness and size for your specific application.

-

Cost Analysis: Evaluate the cost of 5052 aluminum plate compared to other materials to ensure it fits within your budget.

Conclusion

In summary, the 5052 aluminum plate is a superior choice for marine applications due to its corrosion resistance, strength, and weldability. Whether you’re building a boat hull, marine tanks, or other marine equipment, this alloy provides excellent performance in harsh saltwater environments. By considering the factors outlined in this article, you can make an informed decision about whether 5052 aluminum plate is the right choice for your project.

For high-quality 5052 aluminum plate tailored to your marine needs, contact Shanxi Luokaiwei Steel Company. With years of experience and a commitment to excellence, they can provide the material solutions you need for your marine projects.

📧 Email: sales@luokaiweipipe.com

📱 WhatsApp: +86 18912200505