What Makes Color Coated Galvalume Steel Coil Superior for Roofing and Walling?

When it comes to constructing durable and aesthetically pleasing roofs and walls, selecting the right material is crucial. Color Coated Galvalume Steel Coil (PPGL) has emerged as a top choice in the building industry. This article delves into the reasons behind its popularity, comparing it with other materials, and providing practical insights for its application.

🧪 What Is Color Coated Galvalume Steel Coil?

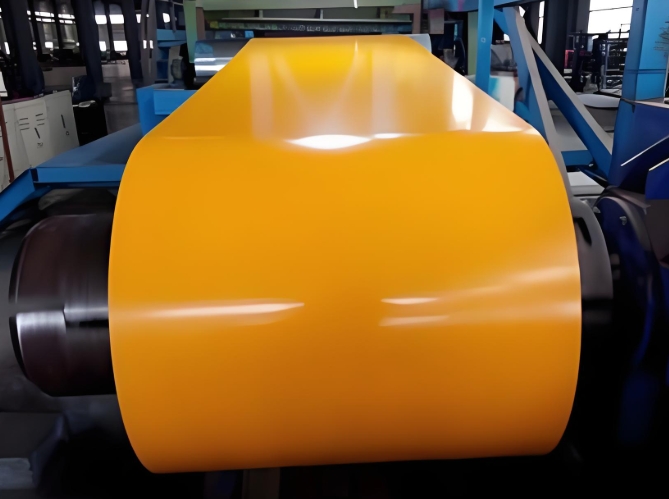

Color Coated Galvalume Steel Coil is a steel substrate coated with a combination of aluminum and zinc, offering enhanced corrosion resistance. The addition of a pre-painted layer provides aesthetic appeal and further protection against environmental elements. This combination makes PPGL an ideal material for roofing and walling applications.

✅ Advantages of Color Coated Galvalume Steel Coil

1. Superior Corrosion Resistance

The aluminum-zinc alloy coating on PPGL provides exceptional resistance to corrosion, especially in coastal and industrial environments. This ensures longevity and reduces maintenance costs. According to industry standards, the service life of Galvalume-coated sheets can reach up to 25 years, outperforming traditional galvanized sheets.

2. Aesthetic Appeal

PPGL coils are available in a wide range of colors and finishes, allowing for versatile design options. Whether it’s a sleek modern look or a traditional appearance, PPGL can meet various architectural styles.

3. Lightweight and Easy to Handle

Compared to traditional materials like concrete or clay tiles, PPGL is lightweight, making transportation and installation more efficient. This can lead to reduced labor costs and faster project completion times.

4. Energy Efficiency

The reflective surface of PPGL coils helps in reducing heat absorption, leading to lower energy consumption for cooling in buildings. This contributes to energy savings and a more sustainable building environment.

5. Durability and Low Maintenance

The pre-painted coating on PPGL provides an additional layer of protection against UV rays, moisture, and pollutants. This results in reduced fading and degradation over time, ensuring that the roofing and walling materials maintain their appearance and functionality.

🆚 PPGL vs. Other Roofing Materials: A Comparative Analysis

| Feature | PPGL Steel Coil | Galvanized Steel Coil | Asphalt Shingles |

|---|---|---|---|

| Corrosion Resistance | Excellent | Moderate | Poor |

| Aesthetic Variety | High | Limited | Moderate |

| Weight | Lightweight | Moderate | Heavy |

| Installation Ease | Easy | Moderate | Easy |

| Lifespan | 25+ years | 10-15 years | 15-20 years |

| Maintenance | Low | Moderate | High |

As evident from the table, PPGL offers superior corrosion resistance, aesthetic variety, and a longer lifespan compared to other materials, making it a cost-effective choice in the long run.

🛠️ Step-by-Step Guide to Installing PPGL Roofing and Walling

-

Preparation: Ensure the substrate is clean, dry, and free from debris.

-

Measurement: Accurately measure the area to determine the amount of PPGL required.

-

Cutting: Use appropriate tools to cut the PPGL coils to the desired size, ensuring clean edges.

-

Installation: Begin installation from the bottom edge, overlapping each panel to prevent water ingress.

-

Securing: Fix the panels using suitable fasteners, ensuring they are tight but not overdriven to avoid damaging the material.

-

Finishing: Apply sealants to joints and edges to enhance waterproofing and aesthetic appeal.

⚠️ Common Misconceptions About PPGL Steel Coil

❌ Misconception 1: PPGL is Expensive

While the initial cost of PPGL may be higher than some materials, its durability and low maintenance requirements make it a cost-effective choice over time.

❌ Misconception 2: PPGL is Not Environmentally Friendly

PPGL is recyclable, and its reflective properties contribute to energy savings, making it an environmentally sustainable option.

❌ Misconception 3: PPGL is Difficult to Install

With proper training and tools, PPGL can be installed efficiently, reducing labor costs and installation time.

✅ Practical Checklist for Using PPGL Steel Coil in Roofing and Walling

-

Material Selection: Choose PPGL coils with appropriate coatings and finishes for the specific environmental conditions.

-

Design Planning: Incorporate proper drainage and ventilation in the design to enhance the performance of PPGL installations.

-

Installation: Follow manufacturer guidelines and industry best practices during installation to ensure optimal performance.

-

Maintenance: Regularly inspect and clean PPGL surfaces to maintain their appearance and functionality.

-

End-of-Life Management: Plan for the recycling or repurposing of PPGL materials at the end of their service life to minimize environmental impact.

🧠 Final Thoughts

Color Coated Galvalume Steel Coil has proven to be a superior choice for roofing and walling applications due to its combination of durability, aesthetic appeal, and environmental benefits. By understanding its advantages and following best practices in its application, builders and homeowners can ensure long-lasting and cost-effective structures.