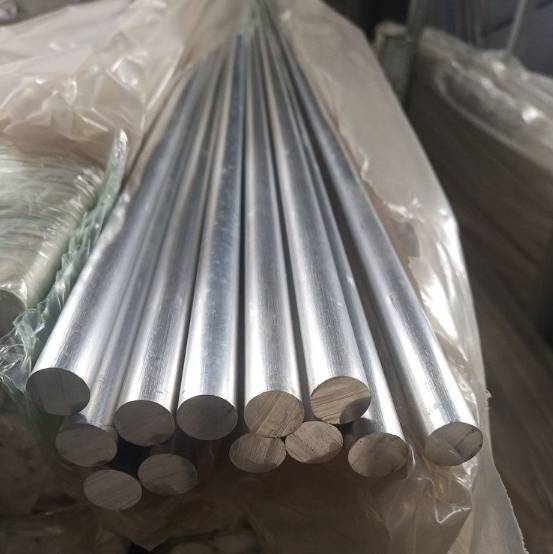

When selecting aluminum alloys for various applications, understanding their properties is essential. Among popular choices are 3003 en 6061 aluminum alloys. This guide provides an in-depth comparison, detailed processing steps, common pitfalls, and a practical checklist to ensure optimal results.

Product Overview: 3003 Aluminum Alloy vs. 6061 Aluminum Alloy

| Kenmerk | 3003 Aluminum Alloy | 6061 Aluminum Alloy |

|---|---|---|

| Primary Alloying Element | Manganese | Magnesium and Silicon |

| Typical Strength | Medium | Hoog |

| Formability | Uitmuntend | Goed |

| Corrosion Resistance | Goed | Very Good |

| Welding Compatibility | Uitmuntend | Goed |

| Typical Applications | Roofing, siding, cooking utensils, tanks | Structural components, lugvaart, automotive parts |

Technical Data Comparison Table

| Property | 3003 Aluminum Alloy (O, H14, H18) | 6061 Aluminum Alloy (T6) |

|---|---|---|

| Chemical Composition (%) | ||

| – Silicon | Max 0.6 | 0.4 – 0.8 |

| – Iron | Max 0.7 | Max 0.7 |

| – Copper | Max 0.05-0.2 | Max 0.15 |

| – Manganese | 1.0 – 1.5 | Max 0.15 |

| – Magnesium | None | 0.8 – 1.2 |

| Mechanical Properties | ||

| – Tensile Strength (ksi) | 16 (O), 22 (H14), 29 (H18) | 35 – 45 (T6) |

| – Yield Strength (ksi) | 6 (O), 21 (H14), 27 (H18) | 30 – 40 (T6) |

| – Elongation (%) | 30 (O), 3 (H14, H18) | 12 – 20 |

Comparison Analysis: Key Differences

- Strength: 6061 offers higher tensile and yield strength, suitable for load-bearing applications.

- Formability: 3003 excels in bending and shaping, making it ideal for decorative and container use.

- Corrosion Resistance: 6061 surpasses 3003, especially after anodizing.

- Weldability: Both alloys weld well, but 3003 is more forgiving for simple welding tasks.

- Cost: 3003 is generally more affordable, suitable for less demanding applications.

Step-by-Step Manufacturing and Processing Guide

Step 1: Materiële seleksie

Identify your application needs—choose 3003 for excellent formability and corrosion resistance or 6061 for high strength and structural integrity.

Step 2: Cutting and Shaping

Use appropriate tools—shears for thin sheets, CNC machines for precision cuts. Ensure the material is at room temperature to avoid deformation.

Step 3: Forming and Bending

For 3003, employ bending techniques with minimal force. For 6061, use proper dies to prevent cracking due to higher strength.

Step 4: Welding

Use compatible welding methods—TIG or MIG. Preheat if necessary, especially for 6061, to prevent cracking.

Step 5: Finishing and Surface Treatment

Apply polishing, anodizing, or painting. 6061 responds well to anodizing, enhancing corrosion resistance.

⚠️ Common Pitfalls and Warnings

- ⚠️ Over-bending: Excessive bending of 6061 can cause cracking. Always follow manufacturer guidelines.

- ⚠️ Improper welding: Using incompatible welding techniques may weaken the joint, especially with 6061.

- ⚠️ Surface damage: Avoid scratching or rough handling during processing to prevent corrosion.

- ⚠️ Misapplication: Do not use 3003 in high-stress environments; it is not designed for structural load-bearing.

Practical Checklist for Aluminum Alloy Projects

- Confirm application requirements: strength, formability, corrosion resistance.

- Select appropriate alloy: 3003 for formability, 6061 for strength.

- Prepare tools and equipment suitable for alloy type.

- Follow correct cutting, bending, and welding procedures.

- Perform surface treatments as needed.

- Inspect all joints and surfaces for damage or defects.

- Test final product for compliance with specifications.

Conclusion

Choosing between 3003 en 6061 aluminum alloys depends on your specific project needs. 3003 offers superior formability and cost-effectiveness, while 6061 provides higher strength and durability. Proper understanding of their properties, careful processing, and adherence to best practices will ensure the success of your aluminum applications.