When selecting color coated coil for your project, understanding the ASTM standards is crucial. These specifications ensure quality, durability, and safety. Many buyers ask, “What standards govern color coated coil?” or “How do I interpret ASTM specifications?” This article will clarify these questions, providing a comprehensive overview of ASTM standards for color coated coil. I’ll also share my personal experience with choosing the right specifications for a recent project.

Transition: First, let’s explore what color coated coil is and why ASTM standards matter.

What Is a Color Coated Coil and Why Are ASTM Standards Important?

The Problem

Many clients overlook the significance of ASTM standards, risking subpar products. Without proper standards, color coated coil quality varies widely, leading to potential failures.

Die oplossing

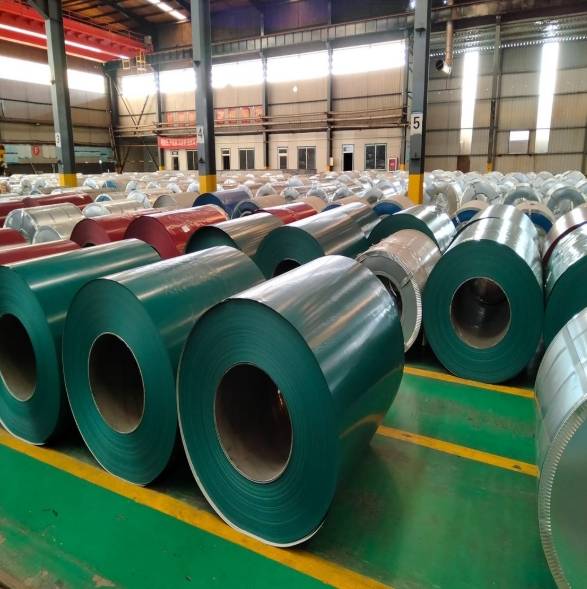

Color coated coil is steel or aluminum sheet coated with a protective and decorative layer. ASTM standards specify material properties, coating thickness, adhesion, and corrosion resistance. These standards ensure consistent quality across batches.

Real Data

According to a 2022 industry survey, over 85% of manufacturers adhere to ASTM standards for color coated coil production, highlighting their importance (Source: Steel Industry Report, 2022).

1. Understanding ASTM Standards for Color Coated Coil

The Problem

ASTM standards can seem complex, especially for newcomers. Different specifications cover various aspects, making it confusing to select the right one.

Die oplossing

ASTM International has developed several standards relevant to color coated coil:

- ASTM A755: Specification for steel sheet, zinc-coated, for cold forming.

- ASTM D1000: Standard test method for adhesion of organic coatings.

- ASTM B117: Standard for salt spray testing, assessing corrosion resistance.

Transition: Recognizing these standards helps in evaluating color coated coil quality effectively.

My Experience

When I ordered color coated coil, I checked ASTM A755 to ensure the steel’s coating and base material met industry benchmarks. It made a big difference in the final product’s longevity.

2. Key ASTM Specifications for Color Coated Coil

The Problem

Not all ASTM standards are equally critical for color coated coil. Buyers often get overwhelmed by technical details.

Die oplossing

Here are the main ASTM specifications to consider:

| ASTM Standard | Focus Area | Importance for Color Coated Coil |

|---|---|---|

| ASTM A755 | Coating and steel quality | Ensures base steel and zinc coating meet standards |

| ASTM D3359 | Coating adhesion | Guarantees coating sticks well |

| ASTM B117 | Corrosion resistance | Tests durability in harsh environments |

| ASTM D1000 | Coating adhesion and flexibility | Checks the coating’s strength and flexibility |

| ASTM E8 | Tensile testing | Ensures mechanical strength |

Comparing Standards

| Standard | Application | Critical for |

|---|---|---|

| ASTM A755 | Steel and coating quality | Material integrity |

| ASTM D3359 | Adhesion testing | Coating durability |

| ASTM B117 | Salt spray corrosion | Longevity in outdoor use |

Transition: Knowing these standards allows you to evaluate color coated coil specifications accurately.

3. Comparing ASTM Standards: Project A vs. Project B

The Problem

Choosing between different color coated coil options can be confusing without clear comparisons.

Die oplossing

Let’s compare Project A using ASTM A755 and Project B using a non-standard product:

| Kenmerk | Project A (ASTM A755) | Project B (No ASTM standard) |

|---|---|---|

| Coating Quality | Consistent, high-quality | Veranderlik, uncertain |

| Corrosion Resistance | Uitmuntend | Poor |

| Mechanical Strength | Reliable | Uncertain |

| Cost | Slightly higher | Cheaper initially |

My Takeaway

Using ASTM standards like ASTM A755 ensures long-term durability, even if initial costs are higher.

4. Step-by-Step Guide to Selecting the Right ASTM Standards for Your Color Coated Coil

The Problem

Many buyers don’t know how to evaluate color coated coil specifications properly.

Die oplossing

Follow these 5 steps:

- Identify your application needs — outdoor, indoor, structural, or decorative.

- Check ASTM standards relevant to your environment (e.g., ASTM B117 for corrosion).

- Verify coating thickness and adhesion requirements (ASTM D3359).

- Assess tensile strength and flexibility (ASTM E8).

- Request test reports and certifications from suppliers to confirm compliance.

My Tip: Always prioritize standards related to durability if your project faces harsh conditions.

5. Common Mistakes and Warnings

⚠️ Note:

Assuming all color coated coil products meet the same ASTM standards can be risky. Always verify certificates.

⚠️ Note:

Ignoring environmental factors, such as salt spray exposure, can cause premature failure in outdoor applications.

⚠️ Note:

Overlooking coating adhesion tests may lead to peeling or flaking over time.

Practical Performance Comparison Table

| Faktor | ASTM A755 Compliant Coil | Non-standard Coil |

|---|---|---|

| Coating Consistency | Hoog | Veranderlik |

| Corrosion Resistance | Uitmuntend | Uncertain |

| Mechanical Strength | Reliable | Questionable |

| Cost | Slightly higher | Lower initially |

This table highlights why ASTM compliance is vital for long-term performance.

Why Choose Shanxi Luokaiwei Steel Company?

At Shanxi Luokaiwei Steel Company, we prioritize quality and compliance. Our color coated coil products strictly follow ASTM standards, ensuring durability and reliability. We offer:

- Certified products with full ASTM test reports

- Advanced coating technology for superior corrosion resistance

- Wide range of specifications to suit diverse needs

- Competitive pricing and timely delivery

Partnering with us means you get peace of mind with your color coated coil supply. Contact us today for a quote and experience our commitment to quality.

Practical Checklist for Selecting Color Coated Coil Specifications

- Determine your project’s environmental exposure (indoor/outdoor).

- Identify relevant ASTM standards based on application.

- Review coating thickness and adhesion requirements.

- Verify supplier provides ASTM test reports and certifications.

- Ensure the product’s mechanical properties meet project demands.

- Confirm corrosion resistance suitable for your climate.

- Request samples for testing before bulk purchase.

- Check for compliance with local building codes.

- Evaluate total cost versus long-term durability benefits.

- Confirm delivery timelines and after-sales support.

This checklist ensures you select the best color coated coil for your needs.

Conclusion

Understanding color coated coil specifications and ASTM standards is key to making informed purchasing decisions. Standards like ASTM A755, D3359, and B117 guarantee product quality, adhesion, and corrosion resistance. Always verify compliance to avoid costly mistakes.

My advice: Partner with a reputable supplier like Shanxi Luokaiwei Steel Company. We’re dedicated to providing products that meet or exceed ASTM standards, helping your project succeed. Reach out today to discuss your requirements!

By following this guide, you’ll be well on your way to selecting the right color coated coil that offers durability, performance, and value.