Are you searching for reliable information on metric aluminum plates? Whether you’re a manufacturer, engineer, or hobbyist, understanding the ins and outs of metric aluminum plate is essential. In this comprehensive guide, we’ll explore everything from properties to practical applications, helping you make informed decisions.

What Is a Metric Aluminum Plate?

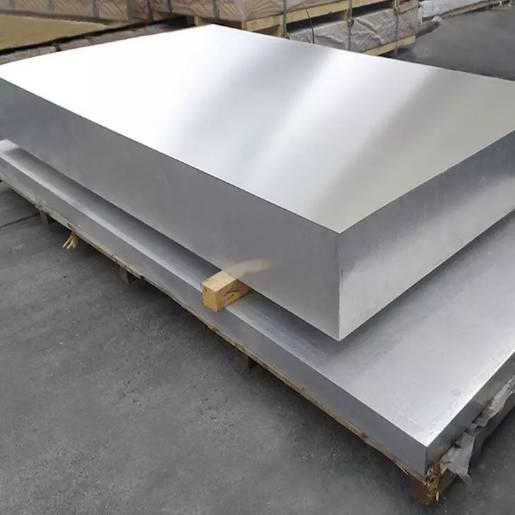

A metric aluminum plate refers to aluminum sheets measured in metric units, typically millimeters. These plates are widely used across industries like aerospace, automotive, and construction due to their lightweight and durability. The main advantage of metric aluminum plate is its precise sizing, which ensures compatibility with various design specifications.

Key Characteristics of Metric Aluminum Plate

- Material Composition: Mostly aluminum alloys like 6061, 7075, en 1050.

- Thickness Range: 1mm to 200mm.

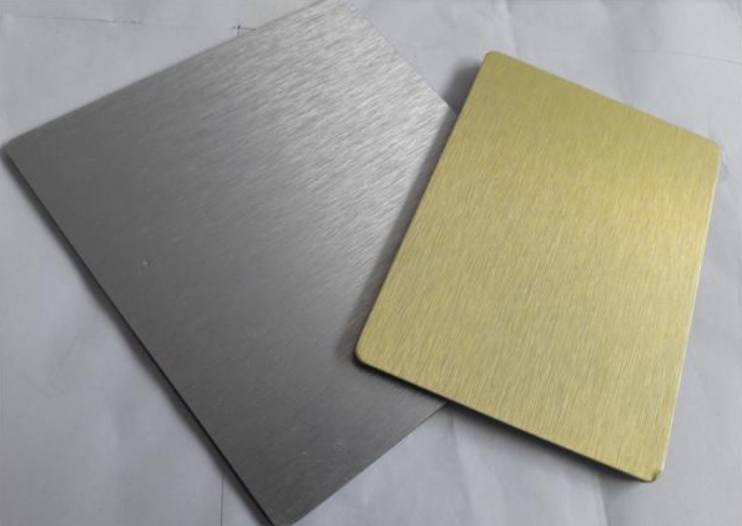

- Surface Finish: Mill finish, anodized, or brushed.

- Density: Approximately 2.7 g/cm³, contributing to lightweight structures.

In my experience, selecting the right alloy significantly impacts performance, especially in high-stress environments.

Properties of Metric Aluminum Plate

Understanding the properties of metric aluminum plate is crucial for selecting the right material for your project.

Mechanical Properties

| Property | Typical Value | Description |

|---|---|---|

| Tensile Strength | 310 MPa (6061-T6) | Resistance to breaking under tension |

| Yield Strength | 276 MPa | Stress at which permanent deformation begins |

| Hardness | 95 HB | Resistance to surface indentation |

Source: Aluminum Association, 2022

Corrosion Resistance

Most metric aluminum plates, especially those made from 1050 or 6061 alloys, demonstrate excellent corrosion resistance, making them suitable for outdoor applications.

Thermal Conductivity

With a thermal conductivity of approximately 235 W/m·K, metric aluminum plates efficiently transfer heat, ideal for heat exchangers.

Applications of Metric Aluminum Plate

Knowing where to use metric aluminum plate can save you time and money. Here are some common applications:

Aerospace Industry

Due to its high strength-to-weight ratio, metric aluminum plate is used in aircraft fuselage and wing components.

Automotive Manufacturing

Lightweight yet durable, these plates are perfect for chassis and structural parts.

Construction and Architecture

Metric aluminum plates are used for decorative panels and structural supports.

Marine Industry

Corrosion-resistant aluminum plates are ideal for shipbuilding and marine equipment.

How to Choose the Right Metric Aluminum Plate

Selecting the ideal metric aluminum plate involves considering several factors:

Step-by-step Buying Guide

- Identify the Application: Determine if strength, corrosion resistance, or thermal conductivity is priority.

- Select the Alloy: For high strength, consider 7075; for corrosion resistance, 1050.

- Determine Thickness: Based on structural requirements, pick the appropriate thickness.

- Check Standards: Ensure the plate meets industry standards like ASTM B209.

- Request Material Certification: Verify alloy composition and mechanical properties.

Comparing Different Alloys

| Property | 6061 | 7075 | 1050 |

|---|---|---|---|

| Strength | Gematig | Hoog | Laag |

| Corrosion Resistance | Goed | Fair | Uitmuntend |

| Weldability | Uitmuntend | Poor | Goed |

This table helps you understand which alloy suits your needs better.

Common Mistakes and How to Avoid Them

⚠️ ⚠注意:

- Choosing the wrong alloy for high-stress environments can lead to failure.

- Ignoring surface finish requirements may affect aesthetics and corrosion resistance.

- Overlooking industry standards could result in non-compliance.

Real-Life Case

Once, I ordered metric aluminum plates without verifying alloy specifications. The plates failed under load because they weren’t suitable for structural use. Always double-check alloy details!

Practical Steps to Work with Metric Aluminum Plate

Here’s a simple 5-step process for cutting and shaping your aluminum plates:

- Measure Accurately: Use calipers for precise dimensions.

- Mark Cutting Lines: Use a permanent marker and straightedge.

- Select Appropriate Tools: Use a fine-tooth saw or CNC machine.

- Cut Carefully: Apply consistent pressure and coolant if necessary.

- Finish Edges: Use a deburring tool for smooth edges.

Tips for Better Results

- Always wear safety gear.

- Use lubricants to reduce tool wear.

- Test cut on scrap material first.

Comparison Table: Metric Aluminum Plate vs. Other Materials

| Kenmerk | Metric Aluminum Plate | Steel Plate | Plastic Plate |

|---|---|---|---|

| Weight | Light | Heavy | Very light |

| Strength | Gematig | Hoog | Laag |

| Corrosion Resistance | Uitmuntend | Poor | Fair |

| Cost | Gematig | Hoog | Laag |

This comparison helps you weigh options based on project needs.

Final Tips for Purchasing Metric Aluminum Plate

- Always request detailed certification.

- Compare prices from multiple suppliers.

- Consider lead times and shipping costs.

- Verify alloy and thickness specifications.

Checklist for Selecting Metric Aluminum Plate

- Define application requirements

- Choose suitable alloy (e.g., 6061, 7075)

- Confirm thickness and dimensions

- Ensure compliance with standards

- Request material certification

- Compare prices and lead times

- Prepare for proper handling and machining

Conclusion

Ter einde, understanding the properties and applications of metric aluminum plate is vital for successful project execution. By following the outlined steps and avoiding common pitfalls, you can select the perfect material for your needs. Remember, thorough research and careful planning make all the difference.