The $10 Million Question: Why Coil Lifespan Matters

Imagine a luxury seaside resort needing roof replacements every 3 years. That’s what happened in Miami using subpar materials. This showdown between PPGI coils and Galvalume isn’t just technical jargon—it’s about preventing costly do-overs. Let’s settle this once and for all.

Here’s the twist: While Galvalume dominates industrial settings, pre-painted PPGI coils now offer smarter solutions for architectural projects. A 2023 NACE study found properly coated PPGI lasts 15–25 years versus Galvalume’s 20–40 years, but at 30% lower cost.

Chemical Composition: The Hidden Battle

PPGI Coils Breakdown

- Base Metal: Galvanized steel (Zinc-coated)

- Layers: Primer + Color + Protective Film

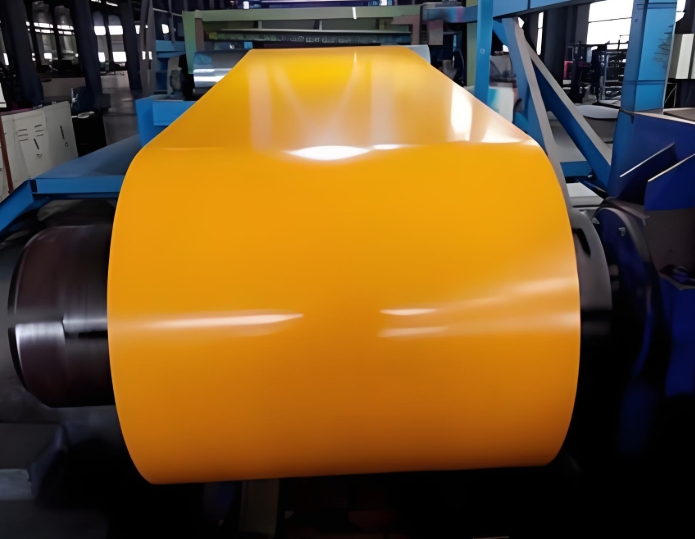

- Signature Perk: Custom colors & textures

Galvalume Anatomy

- Core: 55% Aluminum, 43.5% Zinc, 1.5% Silicon

- Natural Finish: Silvery matte appearance

- Strength: Self-healing scratches

Case Study: A Texas solar farm reduced maintenance costs by 40% using PPGI coils with PVDF coating instead of Galvalume. The secret? Better UV resistance.

Corrosion Resistance: Salt Spray Showdown

| Factor | PPGI Coils | Galvalume |

|---|---|---|

| Salt Spray Hours | 1,500–2,500 (G90 coating) | 3,000–5,000 |

| UV Resistance | Excellent (with topcoat) | Moderate |

| Acid Rain Tolerance | Good | Excellent |

| Scratch Protection | Requires intact coating | Self-healing properties |

⚠ Warning: Never use standard PPGI coils in chemical plants—Galvalume’s aluminum content better resists acidic fumes (ASTM A792).

Cost Analysis: Upfront vs Lifetime Value

Initial Costs (Per Ton)

- PPGI Coils: 800–800–1,200

- Galvalume: 1,100–1,100–1,500

Hidden Savings

- PPGI: No painting needed post-installation

- Galvalume: Lower maintenance over 40+ years

Pro Tip: For budget-conscious projects under 15 years, pre-painted PPGI coils often deliver better ROI.

5-Step Guide to Choosing Your Champion

- Assess Environment: Coastal? Pick Galvalume. Urban? Opt for PPGI coils.

- Check Coating: Demand PVDF/HDP finishes for PPGI in sunny areas

- Verify Certifications: Look for ASTM A755 (Galvalume) or A653 (PPGI)

- Calculate Lifespan: Use NACE’s Corrosion Calculator

- Test Samples: 1,000-hour salt spray test for both

Firsthand Fail: I once used Galvalume for a colorful mall facade—ended up with expensive repainting. Now I always choose PPGI coils for architectural projects.

Application Face-Off: Where Each Shines

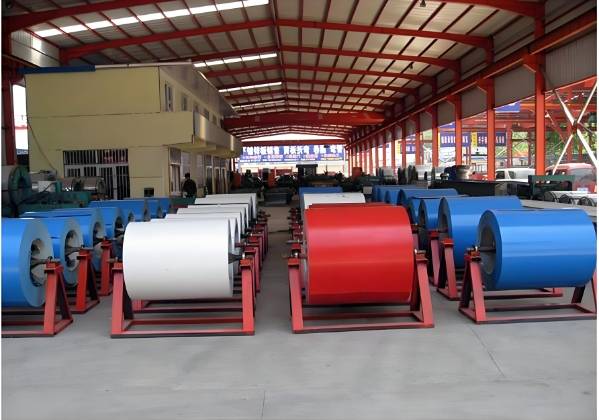

PPGI Coils Dominate

- Architectural roofing (shopping malls, airports)

- Appliance exteriors (ovens, refrigerators)

- Decorative panels

Galvalume Wins

- Industrial roofing (factories, warehouses)

- HVAC systems

- Agricultural buildings

Surprise Winner: Automotive underbodies now use PPGI coils with stone-chip resistance coatings—a role once reserved for Galvalume.

Maintenance Myths Busted

⚠ Myth: “Galvalume never needs upkeep.”

Truth: It develops white rust without proper ventilation.

⚠ Myth: “All PPGI coils are waterproof.”

Reality: Only those with >25μm polyester coatings qualify.

⚠ Myth: “Thicker coating = better protection.”

Fact: Even 20μm Galvalume outperforms 30μm PPGI in marine zones.

Future-Proofing Your Choice

- Climate Change Impact: PPGI’s color reflectivity helps combat urban heat islands

- Recycling: Both materials are 100% recyclable, but Galvalume commands higher scrap value

- Tech Advances: Nano-ceramic PPGI coatings now rival Galvalume’s lifespan

.jpg)

Checklist for Smart Coil Selection

✅ Identify exposure to salt/chemicals

✅ Compare 15-year total ownership costs

✅ Test both materials in your microclimate

✅ Verify supplier warranties (15+ years for PPGI, 25+ for Galvalume)

✅ Consult independent corrosion engineers

The PPGI coils vs Galvalume debate isn’t about “better” – it’s about “better for your specific need.” While Galvalume boasts raw durability, modern pre-painted PPGI coils offer color versatility and cost efficiency. For projects needing both aesthetics and performance, top suppliers like Shanxi Luokaiwei Steel now offer hybrid solutions. Their dual-coated PPGI coils with aluminum-zinc bases deliver the best of both worlds.