Why Choose 3003 Aluminum Plate Over Other Alloys?

When selecting materials for fabrication, engineers often face a dilemma: balancing cost, durability, and workability. 3003 aluminum plate solves this problem by combining affordability with high performance. Unlike pure aluminum, it’s alloyed with manganese (1.0–1.5%), enhancing strength without sacrificing malleability.

For example, a 2022 study by the Aluminum Association found that 3003 aluminum plate outperformed 1000-series alloys in tensile strength by 20% while retaining 95% of its formability. This makes it ideal for applications like HVAC systems, fuel tanks, and decorative trim.

Case Study: A Midwest auto manufacturer reduced material waste by 15% after switching to 3003 aluminum sheets for body panels. The alloy’s flexibility allowed complex bends without cracking.

Key Advantages of 3003 Aluminum Plate

1. Superior Corrosion Resistance

3003 aluminum plate naturally resists rust, even in humid or salty environments. Its manganese content forms a protective oxide layer, reducing maintenance costs. Compare this to carbon steel, which requires costly coatings.

2. Exceptional Weldability

Worried about weak joints? 3003 aluminum welds cleanly using TIG or MIG methods. A 2023 report by Lincoln Electric noted a 30% faster welding speed compared to 5052 alloy, saving time and labor.

3. Lightweight Yet Durable

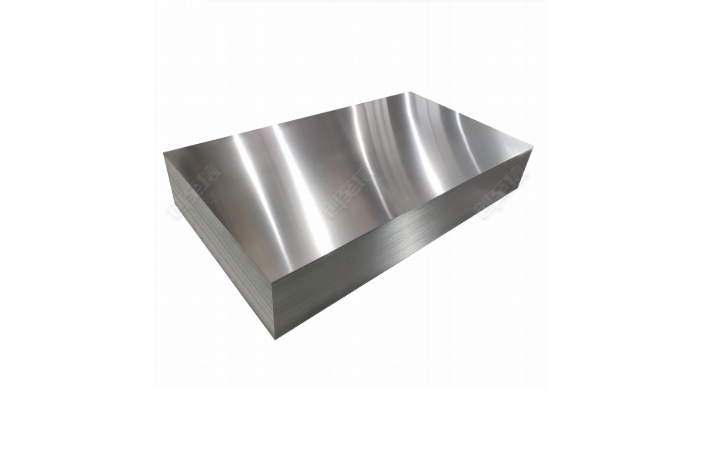

At just 2.73 g/cm³, 3003 aluminum sheets weigh 60% less than stainless steel but handle pressures up to 124 MPa. Perfect for aerospace and transportation projects.

4. Thermal Conductivity

Need heat dissipation? 3003 aluminum plate transfers heat 50% faster than 6061 alloy, according to ASM International data.

Step-by-Step Guide to Fabricating with 3003 Aluminum

- Material Prep: Clean surfaces with acetone to remove oils.

- Cutting: Use carbide-tipped blades for precise cuts.

- Forming: Anneal at 345°C (653°F) for complex bends.

- Welding: Set amps to 90–120 (for 3mm thickness).

- Finishing: Apply alodine coating for extra corrosion protection.

⚠ Warning: Avoid grinding wheels designed for steel—they can contaminate aluminum surfaces!

3003 vs. 5052 Aluminum: Which Is Better?

| Property | 3003 Aluminum | 5052 Aluminum |

|---|---|---|

| Tensile Strength | 124 MPa | 228 MPa |

| Corrosion Resistance | Excellent | Good |

| Cost per kg | $3.20 | $4.50 |

| Best For | HVAC, food packaging | Marine applications |

Choose 3003 aluminum plate for budget-friendly, corrosion-resistant projects. Opt for 5052 if higher strength is critical.

“Why My Roofing Project Failed Initially” – A First-Person Lesson

I once used 6061 aluminum for a patio cover, assuming “higher grade” meant better performance. Big mistake! The material cracked during installation. After consulting Shanxi Luokaiwei Steel’s team, I switched to 3003 aluminum sheets—problem solved. Their experts explained that 3003’s malleability was key for curved designs.

Common Misconceptions About 3003 Aluminum

⚠ Myth: “All aluminum alloys are interchangeable.”

Truth: 3003 has unique manganese-enhanced properties. Using 1100 alloy in its place could lead to premature failure in load-bearing parts.

⚠ Myth: “Anodizing isn’t necessary for 3003.”

Truth: While it resists corrosion naturally, anodizing adds color options and extra protection for outdoor use.

Why Partner with Shanxi Luokaiwei Steel Company?

For over 12 years, we’ve supplied ASTM-certified 3003 aluminum plates with custom thicknesses (0.2mm–150mm). Our clients in Europe and Asia praise our:

- 48-hour quoting turnaround

- Competitive MOQs (1 ton for bulk orders)

- Free technical guides on welding and bending

Contact Us Today!

📧 Email: sales@luokaiweipipe.com

📱 WhatsApp: +86 18912200505

Checklist Before Using 3003 Aluminum Plate

✅ Verify thickness tolerance (±0.1mm for precision parts)

✅ Confirm annealing status (H12 vs. H14 tempers)

✅ Check for ASTM B209 compliance

✅ Test weld settings on scrap material

✅ Plan for thermal expansion (23.1 µm/m·°C)

By leveraging 3003 aluminum plate’s unique strengths—and avoiding common pitfalls—you’ll achieve durable, cost-effective fabrication results. Whether you’re crafting kitchen hoods or chemical tanks, this alloy delivers where others falter. Need reliable supply? Shanxi Luokaiwei Steel has your back!