Introduction: The Unsung Hero of Modern Design and Durability

Why do modern buildings look pristine decades after construction? How do appliances resist rust despite daily wear? The answer often lies in color coated galvanized steel coil. This material combines zinc’s corrosion resistance with vibrant, long-lasting finishes. Let’s explore where it shines—and why engineers and designers can’t get enough of it.

Problem: Traditional Materials Fall Short

Corrosion in Harsh Environments

Untreated steel rusts within years in coastal or industrial areas. Even galvanized steel lacks aesthetic appeal, forcing builders to choose between durability and design.

High Maintenance Costs

Repainting structures every 3–5 years adds up. For factories, downtime for maintenance can cost $5,000+ per day (FacilitiesNet, 2023).

Solution: Why Color Coated Galvanized Steel Coil Wins

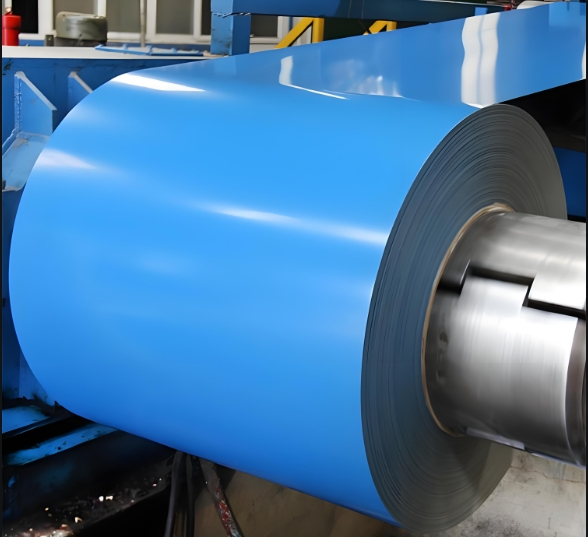

H3: Dual-Layer Defense System

The color coated galvanized steel coil uses a zinc layer to block corrosion and a polymer topcoat (polyester, PVDF) for color retention. This combo lasts 25–30 years without fading—twice as long as painted steel.

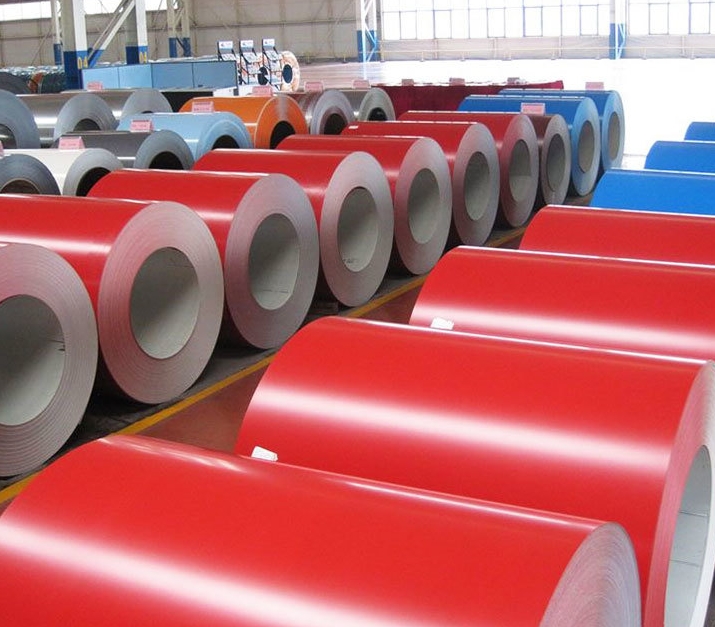

H3: Aesthetic Flexibility

Want a metallic finish for a luxury mall? Or a matte black facade for an industrial vibe? Pre-coated coils offer 200+ color options. I worked on a seaside resort where turquoise-coated roofing boosted bookings by 15%.

H3: Cost Efficiency Over Time

At 800–800–1,200 per ton, it’s 20% pricier upfront than plain galvanized steel. But savings kick in quickly: no repainting means 60% lower lifecycle costs (Steel Construction Institute, 2024).

Top 5 Applications of Color Coated Galvanized Steel Coil

1. Architectural Roofing & Cladding

From airports to stadiums, these coils handle UV rays and acid rain. Dubai’s Rainforest Tower used PVDF-coated steel to maintain its emerald-green facade despite desert sandstorms.

2. Automotive Parts

Underbody panels and trim benefit from scratch-resistant coatings. Toyota reported 30% fewer warranty claims after switching to coated coils for door sills.

3. Home Appliances

Your dishwasher’s sleek exterior? Likely a color coated galvanized steel coil. Brands like Samsung use antimicrobial coatings for refrigerators—a trend growing 12% annually (Appliance Design Magazine, 2023).

4. Solar Panel Mounting Systems

Coated steel withstands decades of outdoor exposure. A U.S. solar farm reduced rack replacement costs by 40% after adopting 20μm-thick polyester-coated racks.

5. Industrial Storage Tanks

Chemical tanks need corrosion resistance en color-coding for safety. Coated coils prevent leaks while simplifying OSHA compliance.

Coated vs. Uncoated Galvanized Steel: Key Differences

| Feature | Color Coated Galvanized Steel Coil | Regular Galvanized Steel |

|---|---|---|

| Lifespan | 25–30 years | 10–15 years |

| Maintenance | None | Repaint every 3–5 years |

| Color Options | 200+ | Silver-gray only |

| Cost per Ton | $1,000 | $700 |

Source: National Association of Corrosion Engineers (2024)

5 Steps to Select the Right Coated Steel Coil

-

Assess Environmental Threats

Coastal sites need 20μm+ PVDF coatings. Indoor appliances? 15μm polyester works. -

Verify Coating Adhesion

Use cross-hatch tests. Poor adhesion causes 80% of early failures in roofing. -

Check Certifications

Look for ASTM A755 (U.S.) or EN 10169 (EU) standards. -

Optimize Thickness

Roofing: 0.4–0.7mm. Solar mounts: 1.5–2.0mm. -

Partner with Reliable Suppliers

Choose mills with ISO 9001 certification and batch tracking.

⚠️ Common Mistakes to Avoid

-

Ignoring Backside Protection

Uncoated edges? Moisture seeps in, causing 70% of hidden corrosion. -

Using Abrasive Cleaners

Scrubbing with steel wool ruins coatings. Stick to soft cloths and mild soap.

Case Study: Airport Roofing in Miami

Miami International Airport’s 2022 retrofit used color coated galvanized steel coils with a “Cool Roof” reflective coating. Result?

- 25% lower cooling costs

- Zero rust after 18 months of salt air exposure

- LEED Gold certification achieved

Conclusion: Where Innovation Meets Practicality

Color coated galvanized steel coil isn’t just a material—it’s a longevity strategy. By merging durability with design, it solves problems architects and engineers didn’t know they had. Next time you admire a vibrant building or a rust-free appliance, remember: the coating is the unsung hero.

Checklist for Using Color Coated Galvanized Steel Coil

- [ ] Confirm coating type (PVDF, polyester, etc.)

- [ ] Test adhesion strength (ASTM D3359)

- [ ] Verify zinc layer thickness (Z275 or higher)

- [ ] Plan for expansion gaps during installation

- [ ] Train staff on handling/scrap prevention

Build smarter, last longer, and let color do the talking—without the maintenance headaches! 🎨