CATEGORIES

FEATURED PRODUCTS

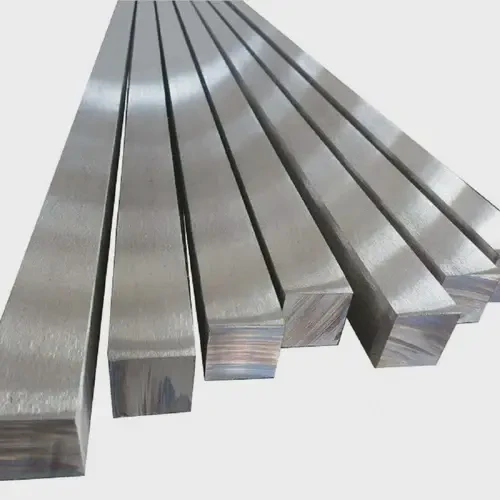

304 Stainless Steel Bar

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

At Luokaiwei, we understand the critical role material selection plays in your projects. That’s why our 304 Stainless Steel Bar represents more than just a commodity metal; it’s a meticulously engineered foundation for reliability and performance across countless demanding environments. As one of the most versatile austenitic stainless steels globally, Type 304 offers an exceptional combination of corrosion resistance, formability, strength, and value. We manufacture our bars to the most stringent standards, ensuring consistency batch after batch, providing you with a dependable material solution you can build upon.

Product Parameters

| Product Name | 304 Stainless Steel Bar | |

| Type | Steel Bar | |

| Outer Diameter | Round Bar | 4mm-500mm |

| Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

| Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

| Flat Steel | 1/2 “to 10”, Thickness: 2mm-150mm, Can provide customized | |

| Length | 1-6 meters, Length can be customized | |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

| Surface | Black, Bright Polished, Rough Turning, Mattness Surface Treatment, No. 4. BA, etc. | |

| Scope of Application | Stainless steel bars are used in a variety of industries such as shipbuilding,

Defense, Automotive, Textiles, Paper and pulp, Manufacturing, Cement, Heavy earthmoving equipment and construction, etc. |

|

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.08 | ≤1.0 | ≤ 2.0 | 18.0~20.0 | 8.0~10.5 | ≤ 0.03 | ≤ 0.035 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥ 520 | ≥ 205 | ≥ 40 | ≤ 187HB ;≤ 90HRB;≤ 200HV |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 8.03 | 193 | 16.9 | 16.2 | 72 |

| No | China | Japan | USA | South Korea | Germany | India | Australia | Taiwan, China | |

| GB | JIS | ASTM | UNS | KS | DIN | BIS | AS | CNS | |

| Austenitic stainless steel | |||||||||

| 1 | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | – | – | 202 |

| 3 | 12Cr17Ni7 | SUS301 | 301 | S20200 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | – | 304N1 | 304N1 |

| 7 | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | – | – | 304N2 | 304N2 |

| 8 | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | – | – | 304LN | 304LN |

| 9 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | – | 305 | 305 |

| 10 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | – | 309S | 309S |

| 11 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | – | 310S | 310S |

| 12 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | – | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | ~02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | – | – | 316N | 316N |

| 16 | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | – | 316LN | 316LN |

| 17 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | – | – | STS316J1 | – | – | 316J1 | 316J1 |

| 18 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | – | – | STS316J1L | – | – | – | 316J1L |

| 19 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | – | – | 317 | 317 |

| 20 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | – | 317L | 317L |

| 21 | 06Cr18Ni11Ti S | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| Duplex stainless steel | |||||||||

| 1 | – | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | – | 329J1 | – |

| 2 | 022Cr23Ni5Mo3N | – | S32205 | F60 | – | 1.4462 | – | 2205 | 2205 |

| 3 | 022Cr25Ni7Mo4N | – | S32750 | F53 | – | 1.4410 | – | 2507 | 2507 |

| Ferritic stainless steel | |||||||||

| 1 | 06Crl3Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 2 | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | – | 409L | 409L |

| 3 | 022Cr12 | SUS410L | – | – | STS410L | – | – | 410L | 410L |

| 4 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 5 | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | – | 434 | 434 |

| 6 | 022Cr18NbTi | – | – | S43940 | – | 1.4509 | – | 439 | 439 |

| 7 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | – | 444 | 444 |

| Martensitic stainless steel | |||||||||

| 1 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | – | – | 403 | 403 |

| 2 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 3 | 20Cr13 | SUS420J1 | 410 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 4 | 30Cr13 | SUS420J2 | – | – | STS420J2 | 1.4028 | 30 Cr13 | 420J2 | 420J2 |

| 5 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | – | – | 440A | 440A |

Material Selection Guide: 304 vs. Key Alternatives

Choosing the right grade is crucial. Below is a comparison highlighting where MWaolloys 304 excels and where alternatives might be necessary:

| Property/Characteristic | MWaolloys 304 | 316/L (Marine Grade) | 430 (Ferritic) | 410 (Martensitic) | Carbon Steel 1045 |

|---|---|---|---|---|---|

| Primary Alloying | 18% Cr, 8% Ni | 16-18% Cr, 10-14% Ni, 2-3% Mo | 16-18% Cr | 11.5-13.5% Cr | Fe-C (~0.45% C) |

| Corrosion Resistance | ★★★★☆ (Excellent – General) | ★★★★★ (Superior – Chlorides/Acids) | ★★☆☆☆ (Fair – Mild Atmos.) | ★★☆☆☆ (Fair – Mild Atmos.) | ★☆☆☆☆ (Poor) |

| Strength (Annealed) | ★★★☆☆ (Medium) | ★★★☆☆ (Medium) | ★★☆☆☆ (Lower) | ★★★☆☆ (Medium) | ★★★★☆ (High) |

| Strength (Hardened) | ★★★★☆ (High via Cold Work) | ★★★★☆ (High via Cold Work) | ★★☆☆☆ (Low) | ★★★★★ (Very High via Heat Treat) | ★★★★★ (Very High via Heat Treat) |

| Ductility & Toughness | ★★★★★ (Excellent) | ★★★★★ (Excellent) | ★★☆☆☆ (Poor) | ★★☆☆☆ (Poor – Hardened) | ★★★☆☆ (Good) |

| Weldability | ★★★★★ (Excellent) | ★★★★★ (Excellent) | ★★★☆☆ (Fair – Limited) | ★★☆☆☆ (Poor – Pre/Post Heat Treat Needed) | ★★★★☆ (Good) |

| Magnetic Response | Typically Non-Magnetic (Slight when Cold Worked) | Typically Non-Magnetic (Slight when Cold Worked) | Magnetic | Magnetic | Magnetic |

| Relative Cost | ★★★☆☆ (Medium) | ★★★★☆ (Higher) | ★★☆☆☆ (Lower) | ★★★☆☆ (Medium) | ★☆☆☆☆ (Lowest) |

| Best Suited For | General corrosion, formability, hygiene, wide temp range | High chloride/acid exposure, marine, chemical | Decorative, non-critical, cost-sensitive | High strength, wear, mild corrosion (hardened) | High strength, wear, no corrosion concern |

Frequently Asked Questions (FAQ)

-

Q: Is MWaolloys 304 stainless steel bar magnetic?

A: Typically, annealed 304 bar is non-magnetic or very slightly magnetic due to its austenitic structure. However, significant cold working (like drawing or heavy bending) can induce a degree of magnetism by partially transforming austenite to martensite. This doesn’t inherently degrade corrosion resistance. -

Q: What’s the difference between 304 and 304L? When should I specify 304L?

A: 304L (“L” for Low carbon) has a maximum carbon content of 0.03% (vs. 0.08% for standard 304). This minimizes the risk of sensitization (chromium carbide precipitation at grain boundaries) during welding or exposure to high temperatures (approx. 425-860°C / 800-1580°F), which can lead to intergranular corrosion. Specify 304L for heavy welded fabrications, components operating in the sensitization range, or critical corrosion applications where post-weld annealing isn’t feasible. -

Q: Can MWaolloys 304 bar be heat treated for higher strength?

A: Unlike martensitic grades (e.g., 410, 420, 440C), 304 cannot be hardened by conventional quenching and tempering heat treatment. Its primary method of increasing strength is through cold working (e.g., cold drawing, rolling, bending). We supply 304 bar in various tempers (e.g., Annealed, 1/4 Hard, 1/2 Hard, Full Hard) indicating the level of cold work and corresponding strength increase. -

Q: How resistant is MWaolloys 304 bar to salt water or de-icing salts?

A: 304 offers only moderate resistance to chlorides. In splash zones, coastal atmospheres, or areas with frequent de-icing salt exposure, pitting and crevice corrosion can occur over time. For such environments, we strongly recommend upgrading to 316/L stainless steel bar, which contains Molybdenum (Mo) for significantly improved pitting resistance. Regular cleaning to remove salt deposits can help prolong 304’s life in milder exposures. -

Q: What surface finishes are available for MWaolloys 304 bar?

A: We offer a range of standard finishes to suit application needs:-

Hot Rolled, Annealed & Pickled (HRAP): Scaled surface removed by pickling, matte grey finish. Economical for non-appearance parts.

-

Centerless Ground: Smoother, more precise dimensional finish. Common for machined components.

-

Turned & Polished (e.g., No. 4 Brushed, BA/Bright Annealed): Superior aesthetic finishes for architectural or visible components. Discuss specific finish requirements (Ra value, grit) with us.

-

-

Q: Does MWaolloys provide test certificates with the bar?

A: Absolutely. Every shipment of MWaolloys 304 bar is accompanied by a detailed Mill Test Report (MTR) or Certificate of Conformance (CoC). This document includes the heat number, chemical composition, mechanical properties (tensile, yield, elongation, hardness), applicable standards (e.g., ASTM A276, A484), heat treatment condition, and dimensional verification. Full traceability is fundamental to our quality commitment.