CATEGORIES

FEATURED PRODUCTS

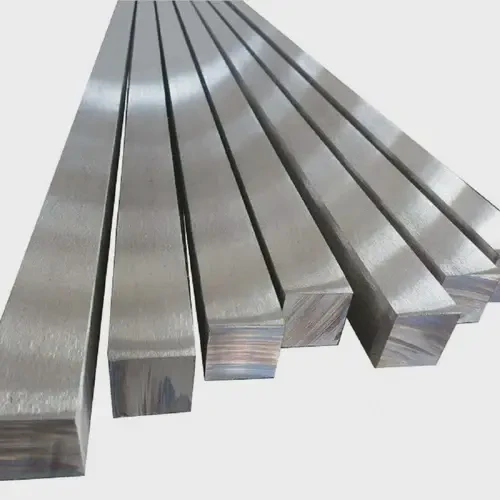

ASTM A582/A582M Stainless Steel Bars

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

We understand that in many high-volume manufacturing processes, machinability is a critical factor for efficiency and cost-effectiveness. The ASTM A582/A582M standard (Standard Specification for Free-Machining Stainless Steel Bars) addresses this directly. It covers hot-finished or cold-finished bars, including rounds, squares, and hexagons, specifically designed for optimum machinability without significantly compromising their inherent corrosion resistance or high-temperature service capabilities.

These specialized stainless steel bars achieve their enhanced machinability through controlled additions of elements like sulfur or selenium. These elements form inclusions within the steel that act as “chip breakers,” reducing friction between the tool and the workpiece, leading to faster machining speeds, longer tool life, and improved surface finish. At Luokaiwei, we meticulously control the composition and processing of these bars to ensure consistent quality and superior performance in your machining operations.

Specifications and Chemical Composition

When selecting ASTM A582/A582M stainless steel bars, understanding the precise chemical composition and other specifications is vital. These details directly influence the material’s machinability, corrosion resistance, and mechanical properties. We ensure our products strictly conform to these requirements.

|

Parameter |

Description |

Typical Values / Requirements (ASTM A582/A582M) |

|

Standard Designation |

American Society for Testing and Materials Specification |

ASTM A582/A582M (Current revision, e.g., -22) |

|

Product Form |

Shapes available under this specification |

Hot-finished or Cold-finished Bars (Rounds, Squares, Hexagons) |

|

Condition |

Heat treatment or processing condition |

Condition A: Annealed |

|

Grades (UNS Designation) |

Common Free-Machining Stainless Steel Types |

Austenitic: S30300 (303), S30323 (303Se), S30345 (303Plus) |

|

Chemical Composition (Weight %) |

Specific elemental ranges for each grade |

(See detailed table below for key elements per common grade) |

|

Carbon (C) |

Influences hardness and strength; max % specified |

Varies by grade (e.g., 303: 0.15 max, 416: 0.15 max, 440F: 0.95-1.20) |

|

Manganese (Mn) |

Improves hot workability and strength |

Varies by grade (e.g., 303: 2.00 max, 416: 1.25 max) |

|

Phosphorus (P) |

Typically controlled to low levels |

0.060 max |

|

Sulfur (S) |

Key element for free-machining, forms manganese sulfides |

0.15 min (for 303, 416, 430F) or 0.15-0.35 (e.g., XM-34) |

|

Silicon (Si) |

Deoxidizer, improves strength and scaling resistance |

1.00 max |

|

Chromium (Cr) |

Provides corrosion resistance and high-temperature strength |

Varies significantly by grade (e.g., 303: 17.0-19.0, 416: 12.0-14.0) |

|

Nickel (Ni) |

Stabilizes austenitic structure, enhances corrosion resistance |

Varies (e.g., 303: 8.0-10.0; often low or absent in martensitic/ferritic) |

|

Molybdenum (Mo) |

Improves pitting corrosion resistance, high-temperature strength |

Varies (e.g., 303: optional addition 1.00 max; 440F: not specified) |

|

Selenium (Se) |

Alternative free-machining additive, often used in 303Se / 416Se |

0.06 min (when specified instead of sulfur) |

Key Chemical Composition Table (Examples)

|

UNS Designation |

Type |

C (max) |

Mn (max) |

P (max) |

S |

Si (max) |

Cr |

Ni |

Mo (max) |

Other |

|

S30300 (303) |

Austenitic |

0.15 | 2.00 | 0.060 |

0.15 min |

1.00 | 17.00-19.00 | 8.00-10.00 | 1.00 |

Cu 0.60 max |

|

S41600 (416) |

Martensitic |

0.15 | 1.25 | 0.060 |

0.15 min |

1.00 | 12.00-14.00 | – | – |

Cu 0.60 max |

|

S44004 (440F) |

Martensitic |

0.95-1.20 | 1.25 | 0.060 |

0.15 min |

1.00 | 16.00-18.00 |

0.50 C |

– |

Cu 0.60 max |

|

S43020 (430F) |

Ferritic |

0.12 | 1.25 | 0.060 |

0.15 min |

1.00 | 16.00-18.00 | – | – | – |

Comprehensive Performance Characteristics

The primary advantage of ASTM A582/A582M stainless steel bars lies in their enhanced machinability, but we also ensure they meet critical mechanical and corrosion resistance standards for reliable performance in their intended applications.

|

Performance Characteristic |

Description |

Typical Performance Data (ASTM A582/A582M Compliance) |

|

Machinability |

Ease of cutting and forming during manufacturing operations |

Excellent, up to 75-85% of B1112 free-machining carbon steel. Reduced tool wear, faster cycle times, improved chip control, better surface finish. |

|

Corrosion Resistance |

Ability to resist degradation from environmental exposure |

Generally good for general atmospheric corrosion, fresh water, and mild chemicals. However, the free-machining additives (S, Se) can slightly reduce pitting resistance compared to non-free-machining grades (e.g., 304, 316). |

|

Tensile Strength |

Maximum stress material can withstand before breaking |

Varies by grade and condition (e.g., 303 Annealed: 600-720 MPa; 416 T condition: 860-1030 MPa). |

|

Yield Strength |

Stress at which material begins to deform permanently |

Varies by grade and condition (e.g., 303 Annealed: 240-510 MPa; 416 T condition: 690-830 MPa). |

|

Hardness (Brinell) |

Resistance to indentation |

Varies by grade and condition (e.g., 303 Annealed: 262 HB max; 416 T condition: 248-302 HB). |

|

Ductility (Elongation) |

Percentage material can stretch before fracturing |

Varies by grade and condition (e.g., 303 Annealed: 35-40%; 416 T condition: 15-20%). |

|

Heat Resistance |

Ability to withstand elevated temperatures without significant degradation |

Varies by grade. Austenitic 303 offers fair resistance up to ~760°C. Martensitic grades like 416 are not recommended for continuous use above their tempering temperature. |

|

Weldability |

Ease of joining by welding processes |

Generally poor for most A582/A582M grades due to high sulfur/selenium content, which can lead to hot cracking. If welding is necessary, special procedures and low-hydrogen electrodes are often required. |

|

Magnetic Properties |

Response to magnetic fields |

Austenitic grades (303, 303Se) are generally non-magnetic in the annealed condition but can become slightly magnetic when cold worked. Martensitic (416, 420F, 440F) and Ferritic (430F) grades are magnetic. |

Common Types and Applications

The ASTM A582/A582M specification covers several stainless steel grades, each with unique characteristics that make them suitable for specific applications where excellent machinability is paramount.

Common Types

-

Type 303 (UNS S30300): This is the most common free-machining austenitic stainless steel. Its high sulfur content provides excellent machinability, while its chromium-nickel content offers good corrosion resistance.

-

Type 303Se (UNS S30323): Similar to 303, but with selenium instead of sulfur for free-machining properties. This offers slightly improved hot working and surface finish compared to sulfur-bearing 303, though it’s less common.

-

Type 416 (UNS S41600): A common free-machining martensitic stainless steel. It can be heat-treated to achieve high hardness and strength, but its corrosion resistance is lower than 303.

-

Type 420F (UNS S42020): A free-machining version of 420 martensitic stainless steel, offering higher carbon content for greater hardness after heat treatment, suitable for cutting applications.

-

Type 440F (UNS S44004): A high-carbon, free-machining martensitic stainless steel that can be hardened to achieve very high strength and wear resistance, often used for cutting tools.

-

Type 430F (UNS S43020): A free-machining ferritic stainless steel. It offers good corrosion resistance in mild environments and is magnetic, but it cannot be hardened by heat treatment.

Common Applications

The superior machinability of A582/A582M bars makes them ideal for various industries where parts are produced on automatic screw machines or CNC lathes.

-

Fasteners: Nuts, bolts, screws, studs, and various threaded components.

-

Shafts: Pump shafts, motor shafts, valve stems, and other rotating components requiring precise machining.

-

Fittings: Valve parts, pipe fittings, couplings, and connectors.

-

Bushings: Precision bushings and spacers.

-

Appliance Components: Parts for household appliances, where volume production and good surface finish are important.

-

Surgical and Dental Instruments: Where high precision machining is required, particularly for 303 and sometimes 416.

-

Automotive Parts: Components for fuel systems, engines, and other parts needing complex shapes and high production rates.

-

Electrical Components: Connectors, terminals, and other intricate parts.

Global Price Comparison: ASTM A582/A582M Stainless Steel Bars

The price of ASTM A582/A582M stainless steel bars varies significantly based on several factors: the specific grade (e.g., 303 vs. 416), the dimensions (diameter, length), the finish (hot-finished, cold-finished, polished), order quantity, and global market conditions for stainless steel raw materials (nickel, chromium, scrap). Below, we provide an indicative price range for ASTM A582 Type 303 Stainless Steel Round Bar (e.g., 25mm diameter, annealed condition), assuming a typical bulk order. Please remember these are approximate figures and subject to change.

|

Region / Country |

Indicative Price Range (USD per Metric Ton) |

Key Factors Influencing Price |

|

China |

$2,000 – $3,500 |

Lower labor and production costs, large manufacturing capacity, competitive raw material sourcing, global shipping rates. |

| USA |

$4,000 – $7,000+ |

Higher domestic labor and operational costs, stringent quality control, domestic material sourcing, faster lead times for North American markets. |

|

India |

$1,800 – $3,200 |

Competitive labor and manufacturing costs, growing steel industry, export focus, raw material availability. |

|

Europe (Germany/UK) |

$3,500 – $6,500 |

High labor costs, advanced manufacturing, strict environmental regulations, raw material import costs. |

Disclaimer: These prices are for general reference only and do not constitute a binding offer. Actual prices can fluctuate daily due to global metal commodity markets, energy costs, freight charges, currency exchange rates, and specific manufacturer/supplier pricing policies. For the most accurate and current quotations, we strongly advise direct communication with reputable suppliers like Luokaiwei.

Luokaiwei: Your Trusted Partner for ASTM A582/A582M Stainless Steel Bars

At Luokaiwei, we are committed to being your premier supplier for ASTM A582/A582M free-machining stainless steel bars. We leverage advanced manufacturing processes and rigorous quality control to ensure every bar meets the precise chemical composition and mechanical properties specified by the standard. Our extensive inventory includes a wide range of sizes and grades, ready to meet your production needs. We pride ourselves on:

-

Strict Adherence to Standards: Ensuring full compliance with ASTM A582/A582M specifications.

-

Optimal Machinability: Providing bars that minimize tool wear and maximize production efficiency for your operations.

-

Consistent Quality: Implementing comprehensive testing and inspection protocols from raw material to finished product.

-

Global Reach: Offering competitive pricing and reliable logistics to clients worldwide.

-

Expert Support: Our team is ready to assist you in selecting the perfect grade and dimensions for your specific application.

We are confident that when you choose Luokaiwei, you’re choosing a partner dedicated to your success, providing materials that perform exactly as expected, every time.

Frequently Asked Questions (FAQs)

We’ve compiled some of the most common questions about ASTM A582/A582M stainless steel bars to help you further understand their properties and applications.

Q1: Why is ASTM A582/A582M specifically called “free-machining”?

ASTM A582/A582M is called “free-machining” because the stainless steel grades covered by this specification contain controlled additions of elements like sulfur (S) or selenium (Se). These elements form tiny inclusions (e.g., manganese sulfides) within the steel’s microstructure that act as internal chip breakers during machining. This reduces friction, lowers cutting forces, and results in shorter, more manageable chips, significantly improving the material’s machinability compared to standard stainless steel grades like 304 or 316.

Q2: How does the addition of sulfur or selenium affect other properties of the stainless steel?

While sulfur and selenium significantly improve machinability, they can have a slight trade-off. They tend to slightly reduce the corrosion resistance, particularly pitting corrosion, compared to non-free-machining versions of the same grade (e.g., 303 vs. 304). Additionally, these additions generally reduce the weldability of the material, making it more prone to hot cracking during welding. Therefore, A582/A582M grades are typically chosen for applications where machinability is critical and extensive welding or severe corrosion environments are not primary concerns.

Q3: What is the typical surface finish of ASTM A582/A582M bars?

ASTM A582/A582M bars can be supplied in various finishes, including hot-finished (black, as-rolled) or cold-finished (e.g., cold drawn, centerless ground, polished). Cold-finished bars generally offer tighter dimensional tolerances, a smoother surface finish, and improved mechanical properties (increased strength) due to strain hardening. The specific finish will depend on the end-use application’s requirements.

Q4: Can ASTM A582/A582M stainless steel be heat treated?

Yes, the heat treatment capabilities depend on the specific grade. Martensitic grades covered by A582/A582M (e.g., 416, 420F, 440F) can be hardened by heat treatment (quenching and tempering) to achieve very high strength and hardness. Austenitic grades (e.g., 303, 303Se) are generally supplied in the annealed condition to maximize ductility and are not hardenable by heat treatment, though they can be strengthened by cold working. Ferritic grades (e.g., 430F) are also not hardenable by heat treatment.

Q5: What quality control measures does Luokaiwei implement for these bars?

At Luokaiwei, we implement a multi-stage quality control process for our ASTM A582/A582M stainless steel bars. This includes: strict raw material inspection to verify chemical composition, in-process monitoring during hot-finishing or cold-finishing to ensure dimensional accuracy and surface quality, mechanical property testing (tensile, yield, elongation, hardness) in accredited laboratories, and final visual inspection and packaging. We also provide Material Test Certificates (MTCs), traceable to each batch, confirming compliance with the ASTM A582/A582M standard.