CATEGORIES

FEATURED PRODUCTS

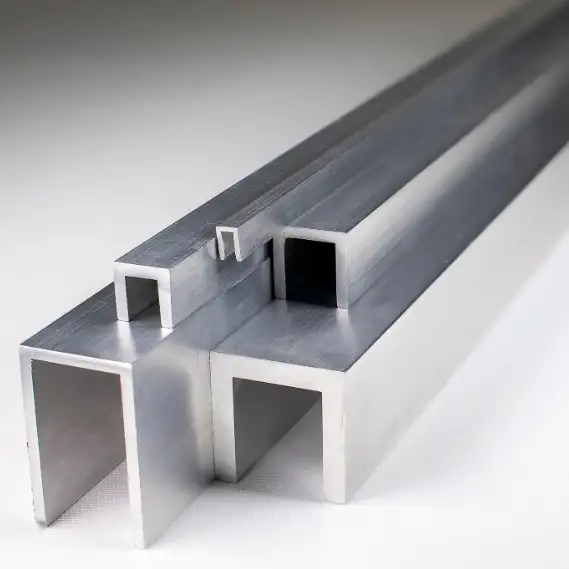

Aluminium Rectangular Tube

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

Aluminium rectangular tubes are hollow sections with four sides and right angles. These tubes are used in applications where strength, weight, and corrosion resistance are important. Aluminium is chosen for its exceptional strength-to-weight ratio, resistance to rust, and ease of fabrication. These tubes are often used in structural applications, architectural designs, and manufacturing processes, providing both aesthetic and functional benefits.

Aluminium rectangular tubes are produced from various aluminium alloys, and the selection of alloy depends on the requirements of the application. With a vast range of applications in industries like construction, transportation, aerospace, and automotive, aluminium rectangular tubes are a versatile material used for many structural and mechanical projects.

1. Types and Grades of Aluminium Rectangular Tubes

Aluminium rectangular tubes come in a variety of grades and alloys, each with distinct mechanical properties. The most common grades of aluminium used for rectangular tubes include:

-

6061: Known for excellent mechanical properties, corrosion resistance, and weldability. It is often used in structural applications.

-

6063: This grade offers good corrosion resistance and is highly recommended for architectural and decorative uses.

-

6082: Known for its high strength, 6082 is ideal for structural applications and is commonly used in bridges and cranes.

-

5052: Offers excellent resistance to saltwater corrosion, making it suitable for marine applications.

These alloys provide different balances of strength, corrosion resistance, and workability, allowing manufacturers to select the right alloy based on specific project needs.

2. Chemical Composition and Strength Performance

The chemical composition of aluminium rectangular tubes varies by alloy, influencing their strength, corrosion resistance, and overall performance. Below are typical compositions for some common grades:

Chemical Composition of Common Aluminium Grades

| Element | 6061 Aluminum | 6063 Aluminum | 6082 Aluminum | 5052 Aluminum |

|---|---|---|---|---|

| Aluminum | Balance | Balance | Balance | Balance |

| Silicon | 0.4 – 0.8% | 0.2 – 0.6% | 0.7 – 1.3% | 0.25 – 0.4% |

| Iron | 0.7% max | 0.35% max | 0.5% max | 0.4% max |

| Copper | 0.15 – 0.4% | 0.1% max | 0.1% max | 0.1% max |

| Manganese | 0.15% max | 0.1% max | 0.6 – 1.2% | 0.1% max |

| Magnesium | 1.0 – 1.5% | 0.45 – 0.9% | 1.2 – 1.8% | 2.2 – 2.8% |

| Chromium | 0.04 – 0.35% | 0.1% max | 0.25% max | 0.1% max |

| Zinc | 0.25% max | 0.1% max | 0.25% max | 0.1% max |

| Titanium | 0.15% max | 0.1% max | 0.1% max | 0.15% max |

Mechanical Properties

The mechanical properties of these alloys, such as yield strength, tensile strength, and elongation, vary depending on the alloy and temper. Below are typical mechanical properties for 6061 aluminium:

| Property | 6061 Aluminum (T6) |

|---|---|

| Tensile Strength | 42,000 – 45,000 psi |

| Yield Strength | 35,000 psi |

| Elongation | 12-17% |

| Hardness | 95 HB |

| Density | 2.70 g/cm³ |

These properties show how aluminium rectangular tubes can provide structural integrity while maintaining a relatively light weight.

3. Applications of Aluminium Rectangular Tubes

Aluminium rectangular tubes are used in a wide range of industries and applications. The following are some of the most common uses:

-

Construction: Aluminium rectangular tubes are used in structural applications, including framing, handrails, and staircases.

-

Automotive and Transportation: Used in the manufacture of vehicle frames, trailers, and other structural parts.

-

Aerospace: Ideal for applications that require high strength and low weight, such as aircraft frames and support structures.

-

Furniture: Aluminium rectangular tubes are used to create modern furniture designs, including tables, chairs, and shelving units.

-

Marine: The corrosion resistance of aluminium makes it ideal for boat frames and other marine applications.

Aluminium’s lightweight nature combined with its strength makes it a preferred material in industries where weight reduction and structural integrity are crucial.

4. Global Standards for Aluminium Rectangular Tubes

Aluminium rectangular tubes are manufactured according to various global standards. The most common standards include:

-

ASTM B221: Standard Specification for Aluminium and Aluminium-Alloy Extruded Bars, Rods, Shapes, and Tubes.

-

ISO 9001: International standard for quality management systems, ensuring that aluminium products meet specific quality standards.

-

EN 755: European standard for the production of aluminium and aluminium alloy extrusions.

These standards ensure consistency and quality in the manufacturing of aluminium rectangular tubes, allowing them to meet specific requirements for strength, durability, and corrosion resistance.

5. Comparison with Other Aluminium Grades

Aluminium rectangular tubes are available in various grades, and each grade offers specific advantages depending on the application. Below is a comparison between 6061, 6063, and 5052 aluminium:

| Property | 6061 Aluminum | 6063 Aluminum | 5052 Aluminum |

|---|---|---|---|

| Tensile Strength | High (42-45 ksi) | Moderate (22-40 ksi) | Moderate (31-37 ksi) |

| Corrosion Resistance | Good | Excellent | Excellent |

| Formability | Moderate | Excellent | Good |

| Weldability | Excellent | Excellent | Good |

| Cost | Higher | Moderate | Moderate |

Key Differences

-

6061 Aluminium: Known for its excellent strength and mechanical properties, it is ideal for structural applications.

-

6063 Aluminium: Preferred for architectural and decorative applications due to its superior finish and excellent extrudability.

-

5052 Aluminium: Offers superior resistance to marine and industrial environments, making it ideal for applications exposed to saltwater.

6. Purchasing Considerations for Aluminium Rectangular Tubes

When purchasing aluminium rectangular tubes, several factors should be considered to ensure the best fit for your needs:

-

Alloy Selection: Choose the appropriate alloy based on the required strength, corrosion resistance, and application.

-

Size and Dimensions: Verify the dimensions (height, width, and wall thickness) to ensure they meet project requirements.

-

Quality Certifications: Ensure the tubes meet international standards such as ASTM B221 or ISO 9001 to guarantee quality.

-

Supplier Reliability: Choosing a trusted supplier like Luokaiwei ensures consistent product quality, on-time delivery, and competitive pricing.

-

Lead Time: Consider the supplier’s ability to deliver within your project timelines, particularly if large quantities are required.

7. Case Study: Aluminium Rectangular Tubes in Aerospace

A leading aerospace company was looking for lightweight and durable materials for structural components in aircraft. They turned to 6061 aluminium rectangular tubes for their combination of strength, lightweight nature, and corrosion resistance. The use of 6061 aluminium allowed the company to reduce the weight of the aircraft by 15%, resulting in increased fuel efficiency and lower operational costs. The tubes were also easily welded, making the manufacturing process more efficient and cost-effective.

8. Frequently Asked Questions (FAQ)

-

What is the difference between 6061 and 6063 aluminium?

6061 aluminium is stronger and more durable, while 6063 aluminium is more suitable for architectural applications due to its excellent surface finish. -

Can aluminium rectangular tubes be welded?

Yes, most grades of aluminium, including 6061 and 6063, can be welded easily, making them versatile for a variety of manufacturing processes. -

Are aluminium rectangular tubes resistant to corrosion?

Yes, aluminium rectangular tubes offer excellent corrosion resistance, particularly in grades like 5052, which is ideal for marine environments. -

What industries use aluminium rectangular tubes?

These tubes are used across industries such as construction, aerospace, automotive, marine, and furniture manufacturing. -

How do I select the right aluminium alloy for my project?

The choice of alloy depends on the application’s requirements for strength, corrosion resistance, and formability. For high-strength applications, 6061 is recommended, while for decorative purposes, 6063 is ideal.