CATEGORIES

FEATURED PRODUCTS

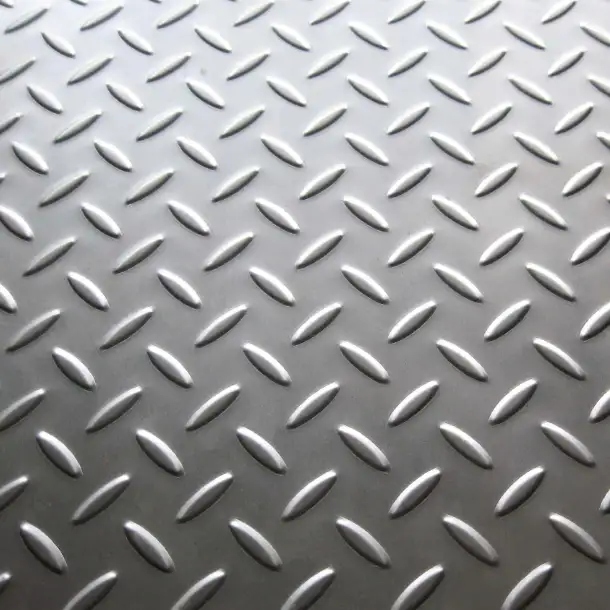

410 Stainless Steel Plate

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

410 stainless steel is a widely used martensitic stainless steel that contains 11.5-13.5% chromium. This steel grade offers good resistance to oxidation, moderate corrosion resistance, and high strength. The alloy’s ability to resist corrosion in mildly corrosive environments makes it ideal for applications such as valves, pumps, and chemical processing equipment.

The unique feature of 410 stainless steel is that it can be hardened by heat treatment, unlike other austenitic stainless steels. Its hardness and resistance to wear make it suitable for components like shafts, gears, and cutting tools. Additionally, it is known for its high tensile strength and ability to maintain mechanical properties at high temperatures.

1. Chemical Composition of 410 Stainless Steel Plate

Understanding the chemical composition of 410 stainless steel is crucial for determining its performance in specific applications. The primary elements include:

-

Chromium (Cr): 11.5-13.5% – Provides corrosion resistance and hardness.

-

Carbon (C): 0.08-0.15% – Contributes to hardness and strength.

-

Manganese (Mn): 1.0% max – Enhances strength and toughness.

-

Silicon (Si): 1.0% max – Improves oxidation resistance.

-

Phosphorus (P): 0.04% max – Limits corrosion resistance.

-

Sulfur (S): 0.03% max – Affects machinability.

These elements combine to give 410 stainless steel its excellent mechanical properties, making it ideal for many industrial uses.

2. Key Properties of 410 Stainless Steel Plate

410 stainless steel plates are characterized by several key properties that contribute to their widespread use in various industries. These properties include:

-

High Strength: Offers excellent tensile strength, making it suitable for high-stress environments.

-

Wear Resistance: The material resists abrasion and wear, making it ideal for use in machinery components.

-

Heat Resistance: It can withstand high temperatures, up to 700°F (370°C), without significant degradation.

-

Corrosion Resistance: While not as corrosion-resistant as austenitic stainless steels, 410 still offers moderate resistance to corrosion, especially in mildly corrosive environments.

-

Hardness: 410 can be hardened through heat treatment, making it versatile for different applications requiring varying levels of hardness.

3. 410 Stainless Steel Plate Applications

410 stainless steel plates are used in a variety of applications across industries. Some common uses include:

-

Machinery Parts: Its wear resistance and high strength make it ideal for parts like valves, pumps, and shafts.

-

Food Processing Equipment: Its moderate corrosion resistance allows it to be used in food processing machinery and parts that come into contact with food.

-

Medical Devices: Surgical tools and other medical instruments benefit from the alloy’s corrosion resistance and ease of sterilization.

-

Automotive: Used in the manufacture of exhaust systems, gears, and bearings.

-

Chemical Processing: Often used in pumps and valves that need to withstand high temperatures and moderate corrosion.

Table: Comparison of 410 Stainless Steel Plate with Other Grades

| Property | 410 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel | 430 Stainless Steel |

|---|---|---|---|---|

| Corrosion Resistance | Moderate | Good | Excellent | Poor |

| Hardness | High (HRC 40-45) | Medium (HRC 20-30) | Medium (HRC 20-30) | Low (HRC 10-20) |

| Strength (Tensile) | High | Moderate | Moderate | Low |

| Heat Resistance | 700°F (370°C) | 800°F (427°C) | 850°F (454°C) | 1500°F (815°C) |

| Applications | Mechanical parts | Food, medical | Marine, chemical | Household items |

4. Price Comparison: 410 Stainless Steel Plate in China, USA, and India

The price of 410 stainless steel plates varies depending on the region. Generally, prices are influenced by factors such as the cost of raw materials, labor, and transportation, as well as local demand.

-

China: Prices in China are typically lower due to the country’s massive production scale and low labor costs. Prices can range from $2.00 to $3.50 per kg for 410 stainless steel plates.

-

USA: In the United States, the cost of 410 stainless steel plates is higher, typically ranging from $3.50 to $6.00 per kg. This is due to higher labor and operational costs, as well as import duties on foreign steel.

-

India: India’s prices are relatively lower compared to the USA, typically ranging from $2.50 to $4.00 per kg. India’s price point benefits from competitive labor costs and a growing domestic steel industry.

Table: Price Comparison of 410 Stainless Steel Plates

| Region | Price Range (per kg) |

|---|---|

| China | $2.00 – $3.50 |

| USA | $3.50 – $6.00 |

| India | $2.50 – $4.00 |

Factors Affecting Prices

Several factors contribute to the pricing differences across regions:

-

Raw Material Costs: The cost of chromium, a primary component in 410 stainless steel, plays a significant role in pricing.

-

Production Costs: Labor, electricity, and other operational costs vary from region to region.

-

Import/Export Tariffs: International shipping costs, tariffs, and trade policies impact the final price.

-

Supply and Demand: Regional demand for stainless steel products can drive prices up or down.

5. Purchasing Considerations for 410 Stainless Steel Plate

When purchasing 410 stainless steel plates, several key considerations should be taken into account:

-

Supplier Reputation: Choose a reliable supplier like Luokaiwei, known for its high-quality stainless steel products and commitment to timely delivery.

-

Material Specifications: Ensure the material meets the required ASTM, EN, or GB standards.

-

Quantity and Lead Time: Larger orders may attract better pricing, and the lead time for delivery should be considered based on project requirements.

-

Price Fluctuations: Be aware of fluctuations in material prices due to global demand and market conditions.

-

Certification and Quality Control: Ensure that the steel plates come with appropriate certifications, such as ISO or CE, to guarantee quality.

6. Case Study: Use of 410 Stainless Steel in Automotive Manufacturing

A major automotive manufacturer in the USA needed a material that could withstand high temperatures and mechanical stress in the production of exhaust components. They chose 410 stainless steel plates for their high strength and resistance to wear. After switching to 410 stainless steel, the manufacturer reported a 20% increase in the lifespan of critical components and a reduction in maintenance costs.

7. Frequently Asked Questions (FAQ)

-

What is the difference between 410 and 304 stainless steel?

410 stainless steel is a martensitic alloy that can be hardened through heat treatment, while 304 is an austenitic alloy known for superior corrosion resistance but not as hard. -

Is 410 stainless steel magnetic?

Yes, 410 stainless steel is magnetic due to its martensitic structure. -

Can 410 stainless steel be welded?

Yes, 410 stainless steel can be welded, but it may require pre-heating and post-weld heat treatment to avoid cracking. -

What industries use 410 stainless steel plates?

410 stainless steel plates are used in various industries, including automotive, aerospace, food processing, and chemical processing. -

How do I choose the right stainless steel plate for my project?

Consider factors such as strength, corrosion resistance, hardness, and application requirements when choosing a stainless steel plate.