CATEGORIES

FEATURED PRODUCTS

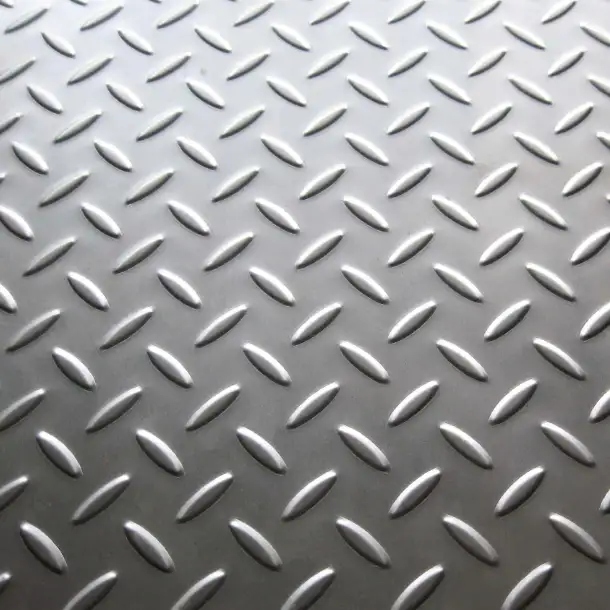

Stainless Steel Checker Plate

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

A stainless steel checker plate, also known as tread plate or chequered plate, is a flat sheet of stainless steel with a raised diamond or linear pattern on one side. This design not only adds aesthetic appeal but provides excellent slip resistance, making it ideal for industrial flooring, stairs, ramps, and loading docks.

Checker plates are commonly produced using hot rolling or cold rolling methods, depending on the thickness and application. Available in 304, 316, 430, and other stainless steel grades, they are widely favored for their corrosion resistance, durability, and hygiene standards.

1. Mechanical & Chemical Properties

The performance of a checker plate is largely dictated by its chemical composition and mechanical strength. Below is a breakdown of typical properties:

| Property | 304 Grade | 316 Grade | 430 Grade |

|---|---|---|---|

| Tensile Strength (MPa) | 520 – 750 | 515 – 760 | 450 – 600 |

| Yield Strength (MPa) | ≥205 | ≥205 | ≥195 |

| Elongation (%) | ≥40 | ≥40 | ≥22 |

| Hardness (HB) | ≤201 | ≤217 | ≤183 |

| Chromium (%) | 18.0 – 20.0 | 16.0 – 18.0 | 16.0 – 18.0 |

| Nickel (%) | 8.0 – 10.5 | 10.0 – 14.0 | 0.0 – 0.75 |

| Molybdenum (%) | 0.0 | 2.0 – 3.0 | 0.0 |

Source: Outokumpu Stainless Steel Handbook (2023)

2. Surface Patterns and Finishes

Common patterns include:

-

Diamond/5-Bar Tread Pattern: Highly slip-resistant.

-

Single Bar Checker: Ideal for lightweight anti-slip use.

-

Circular/Teardrop Patterns: Preferred in decorative applications.

Available surface finishes:

-

2B Finish: Smooth, reflective, mill finish for general industrial use.

-

No. 1 Finish: Rough, hot-rolled finish used in structural applications.

-

BA Finish: Bright annealed for aesthetic applications.

3. Stainless Steel Checker Plate Grades Comparison

Understanding how different grades compare is crucial for optimal selection.

| Grade | Corrosion Resistance | Cost | Machinability | Common Use |

|---|---|---|---|---|

| 304 | Excellent | Moderate | Good | Food factories, commercial floors |

| 316 | Superior (marine) | High | Fair | Offshore, chemical, saltwater areas |

| 430 | Moderate | Low | Very Good | Decorative, less corrosive zones |

| 310S | High (heat-resistant) | Very High | Moderate | Furnace platforms, thermal plants |

4. Global Price Comparison: China vs USA vs India (2025)

Below is a price comparison for standard 4×8 ft, 3mm thick stainless steel checker plates in USD per metric ton as of June 2025.

| Country | 304 Checker Plate | 316 Checker Plate | Lead Time |

|---|---|---|---|

| China | $2,150 – $2,350 | $3,100 – $3,400 | 7 – 10 days |

| USA | $3,200 – $3,600 | $4,400 – $4,700 | 3 – 5 days |

| India | $2,400 – $2,600 | $3,300 – $3,550 | 10 – 14 days |

Note: Prices fluctuate based on alloy surcharge, freight, and exchange rates.

5. Factors Affecting Stainless Steel Checker Plate Prices

Price fluctuations are influenced by:

-

Grade and Alloy Content: Higher nickel or molybdenum content raises cost.

-

Global Nickel Price: In May 2025, LME nickel averaged $19,500/ton [LME Source].

-

Surface Finish & Pattern Complexity

-

Order Quantity & Custom Sizes

-

Country of Origin & Export Tariffs

-

Shipping Costs & Logistics Fuel Index

6. Application Industries and Use Cases

Due to its anti-slip and hygienic features, stainless steel checker plate is used across:

-

Marine Platforms: Oil rigs, ship decks, gangways

-

Food & Beverage: Processing zones, cleanrooms

-

Public Transport: Train steps, bus interiors

-

Chemical Factories: Walkways, tank platforms

-

Architectural: Wall cladding, elevators, decorative panels

-

Hospitals & Labs: Sanitary environments

7. Case Study: Offshore Oil Platform Walkways

Project: Gulf of Mexico Deepwater Drilling Station

Client: GlobalEnergy Inc.

Problem: Frequent corrosion and slip accidents on existing mild steel flooring.

Solution: Replaced 800 m² of walkway with 316 stainless steel checker plate supplied by Luokaiwei.

Result:

-

Reduced maintenance costs by 35%

-

Zero slip incidents reported in 12 months

-

Life expectancy extended to 25+ years

8. Procurement Tips & Key Considerations

When sourcing stainless steel checker plate, ask yourself:

-

Are you in a corrosive environment? If so, go for 316.

-

Need food-grade hygiene? Choose 304 with a 2B finish.

-

Budget-tight and low-corrosion? Consider 430 with caution.

Checklist Before Purchasing:

✅ Confirm ASTM A240 or EN10088 compliance

✅ Verify supplier’s ISO certification

✅ Request MTC (Mill Test Certificate)

✅ Consider MOQ and delivery timeline

✅ Review the polishing and pattern sharpness

9. Why Choose Luokaiwei as Your Supplier?

Luokaiwei offers a full range of stainless steel checker plates in all major grades and patterns. Our advantages include:

-

Factory-direct pricing: Save up to 18% on bulk orders.

-

Quick turnaround: 24-hour quotes, global shipping within 7–12 days.

-

Customization: Cut-to-size, different pattern embossing, surface finish options.

-

Global certifications: ISO, SGS, CE marking.

-

Transparent service: Live support, full traceability, third-party inspection available.

Luokaiwei is not just a supplier—we are a strategic partner trusted by more than 3,000 clients globally in 2024.

10. Frequently Asked Questions (FAQ)

Q1: Can I use stainless steel checker plate in outdoor environments?

A1: Yes, especially 304 and 316 grades, which offer superior corrosion resistance in rain, humidity, and coastal areas.

Q2: What’s the standard thickness range?

A2: Most plates range from 1.5mm to 6mm. Thicker plates (up to 12mm) are available on request.

Q3: Is checker plate available in custom dimensions?

A3: Absolutely. Luokaiwei offers custom cutting based on your project specs.

Q4: Which grade should I choose for chemical plant flooring?

A4: Go with 316 for its added molybdenum, which improves chemical resistance significantly.

Q5: How do I verify the authenticity of the material grade?

A5: Always request a Mill Test Certificate (MTC) and consider third-party lab testing if the order value is large.

Luokaiwei offers stainless steel checker plate, including 304, 316, 310S, 321, 409, 410, and duplex variants—tailored to meet ASTM, EN, and GB specifications.