8020 aluminum is a high-performance alloy known for its excellent strength-to-weight ratio, corrosion resistance, and versatility. This alloy is frequently used in various industries, from aerospace to automotive and construction, making it a popular choice for a wide range of applications. Whether you’re an engineer, designer, or procurement manager, understanding the characteristics and uses of 8020 aluminum is crucial for selecting the right material for your projects.

1. What is 8020 Aluminum?

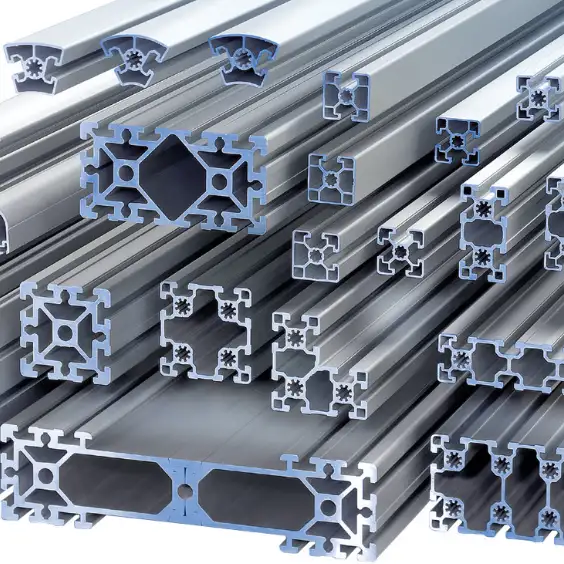

8020 aluminum is a series of aluminum alloys classified under the 8000 series in the Aluminum Association’s alloy numbering system. Known for its versatility, this alloy contains significant amounts of silicon, iron, and copper, making it ideal for manufacturing profiles and extrusions for construction, transportation, and various industrial applications.

Key Properties of 8020 Aluminum

-

Strength: 8020 aluminum offers robust tensile strength, making it suitable for structural and high-load applications.

-

Corrosion Resistance: This alloy is highly resistant to corrosion, especially in humid or marine environments, thanks to its oxide layer.

-

Formability: It is easily extruded, shaped, and fabricated into various components, from bars to custom profiles.

-

Lightweight: Despite its strength, 8020 aluminum remains light, offering excellent weight-saving benefits in applications where weight is a crucial factor.

2. Composition and Alloying Elements

The key elements that make up 8020 aluminum include:

-

Silicon (Si): Improves casting performance and corrosion resistance.

-

Iron (Fe): Provides strength and hardness but may affect machinability.

-

Copper (Cu): Enhances the alloy’s strength but can reduce corrosion resistance slightly.

-

Magnesium (Mg): Typically present in smaller amounts, magnesium increases strength without compromising formability.

By adjusting the proportions of these elements, manufacturers can tailor the alloy to specific requirements, such as increased strength or better corrosion resistance.

3. Applications of 8020 Aluminum

The versatility of 8020 aluminum makes it ideal for a wide range of applications. Here are some of the most common uses:

-

Aerospace Components: 8020 aluminum is often used in aircraft frames, wings, and fuselage components due to its lightweight and strong nature.

-

Structural Extrusions: It is commonly used in structural frames, especially in the construction of conveyor systems, machinery, and vehicle components.

-

Automotive Industry: Car manufacturers use 8020 aluminum for parts such as engine components and structural panels, which require a balance of strength and lightness.

-

Construction and Architecture: Aluminum framing for buildings, windows, and facades often use this alloy for both strength and aesthetic purposes.

4. Advantages and Disadvantages

Advantages

-

Corrosion Resistance: Suitable for use in humid and marine environments.

-

High Strength-to-Weight Ratio: Perfect for weight-sensitive applications like aerospace and automotive.

-

Ease of Fabrication: Easily extruded and machined to meet complex design requirements.

Disadvantages

-

Lower Strength Compared to Other Alloys: While strong, 8020 aluminum does not have the tensile strength of alloys like 7075 aluminum, limiting its use in some heavy-duty applications.

-

Cost: Can be more expensive compared to other aluminum alloys, depending on the grade and processing requirements.

5. Comparison with Other Aluminum Alloys

Here’s a comparison between 8020 aluminum and some other commonly used aluminum alloys:

| Property | 8020 Aluminum | 6061 Aluminum | 7075 Aluminum |

|---|---|---|---|

| Tensile Strength (MPa) | 250-290 | 275-310 | 540-570 |

| Corrosion Resistance | Excellent | Excellent | Good |

| Weight | Lightweight | Moderate | Lightweight |

| Formability | Good | Excellent | Moderate |

| Applications | Structural, aerospace | Construction, automotive | Aerospace, military |

As seen in the table, while 8020 aluminum is a solid choice for structural and aerospace applications, it falls short in terms of tensile strength when compared to 7075 aluminum.

6. Case Study: Use of 8020 Aluminum in Aerospace

One of the notable applications of 8020 aluminum is in the aerospace industry. In 2020, a well-known aerospace company incorporated 8020 aluminum for structural components in its new aircraft design. The material’s light weight and strong resistance to corrosion allowed the company to reduce the overall weight of the aircraft, improving fuel efficiency. As a result, the aircraft’s performance was enhanced, leading to a 5% improvement in fuel economy during test flights.

7. Frequently Asked Questions (FAQs)

Q1: What is the main difference between 8020 aluminum and 6061 aluminum?

A1: The primary difference lies in their strength and application. 8020 aluminum is ideal for lightweight, corrosion-resistant structural applications, while 6061 aluminum offers superior strength and is commonly used in construction, automotive, and marine applications.

Q2: Can 8020 aluminum be welded?

A2: Yes, 8020 aluminum can be welded, but special care should be taken to prevent heat distortion. MIG and TIG welding are the most common methods used.

Q3: Is 8020 aluminum more expensive than other aluminum alloys?

A3: It can be slightly more expensive than some other alloys due to its specific composition and manufacturing processes.

Q4: How does 8020 aluminum perform in extreme temperatures?

A4: 8020 aluminum maintains its strength in a wide range of temperatures, making it suitable for use in both hot and cold environments.

Q5: What industries benefit from 8020 aluminum?

A5: The aerospace, automotive, construction, and manufacturing industries are among the primary beneficiaries of 8020 aluminum due to its strength, durability, and versatility.

9. Price Comparison of 8020 Aluminum: China, USA, and India

When purchasing 8020 aluminum, the price can vary significantly depending on the country of origin, supply chain factors, and the specific requirements of the order. Below is a price comparison between China, the United States, and India, along with the factors that influence these prices.

Price Comparison

| Region | Price per Metric Ton (USD) | Price per Kg (USD) | Price Range |

|---|---|---|---|

| China | $2,200 – $2,500 | $2.20 – $2.50 | Most affordable |

| United States | $3,000 – $3,400 | $3.00 – $3.40 | Premium pricing |

| India | $2,500 – $2,800 | $2.50 – $2.80 | Mid-range price |

Factors Influencing 8020 Aluminum Pricing

-

Raw Material Costs: The price of primary aluminum, which fluctuates based on market conditions and global supply-demand dynamics, is a major factor affecting the overall cost of 8020 aluminum. China, with its abundant raw materials and well-established aluminum production industry, can offer more competitive prices compared to the United States and India.

-

Manufacturing and Labor Costs: The cost of labor and manufacturing processes can significantly influence the price. In countries with lower labor costs, like China and India, manufacturers can offer more competitive prices. Conversely, higher labor costs in the United States contribute to the premium price for 8020 aluminum.

-

Transportation and Tariffs: Shipping costs, import/export tariffs, and transportation fees all contribute to the final price. For instance, tariffs imposed on aluminum imports can increase the price of 8020 aluminum in regions like the United States.

-

Volume and Customization: Bulk purchases or large orders can often secure better pricing, as manufacturers can reduce unit costs by producing larger quantities. Additionally, if you require customized extrusions or specific shapes, these factors will affect the price, particularly in countries like the United States, where precision manufacturing costs tend to be higher.

-

Quality and Certification: Prices also vary based on quality. The United States typically offers higher-quality aluminum alloys, backed by industry certifications like ISO or ASTM standards, which can increase the overall price. However, Chinese manufacturers such as Luokaiwei have a reputation for offering competitive prices without compromising on quality.

10. Why Choose Luokaiwei for 8020 Aluminum Procurement in China

If you’re looking to purchase 8020 aluminum at a competitive price without sacrificing quality, Luokaiwei is an excellent choice for your procurement needs. Here are the key reasons why you should consider Luokaiwei as your supplier:

-

Cost-Effectiveness: Luokaiwei offers some of the most competitive prices in the market, thanks to China’s low manufacturing and labor costs. Their prices are significantly lower than those from the United States and India.

-

High Quality: Despite the lower cost, Luokaiwei maintains high standards of production, ensuring that the aluminum they supply meets international quality standards, such as ISO 9001 and ASTM specifications.

-

Reliable Supply Chain: With years of experience in the aluminum industry, Luokaiwei has built a robust and efficient supply chain, ensuring fast and reliable delivery worldwide.

-

Customization Options: Whether you need standard or custom extrusions, Luokaiwei can meet your exact specifications. Their manufacturing capabilities allow for a wide range of customization options.

-

Excellent Customer Support: Luokaiwei is known for providing exceptional customer service, assisting you through every step of the procurement process, from quotation to delivery.

-

Sustainability: As an environmentally conscious manufacturer, Luokaiwei follows sustainable practices in its production, ensuring minimal environmental impact.

11. Conclusion

The price of 8020 aluminum varies across different regions due to factors such as raw material costs, manufacturing expenses, labor costs, and tariffs. While prices in China are generally more affordable, countries like the United States and India offer higher-quality options, albeit at a higher price. If you are looking for an affordable yet high-quality solution, Luokaiwei is an excellent choice for your aluminum procurement needs. With their competitive pricing and high-quality standards, they provide a reliable option for global customers.