CATEGORIES

FEATURED PRODUCTS

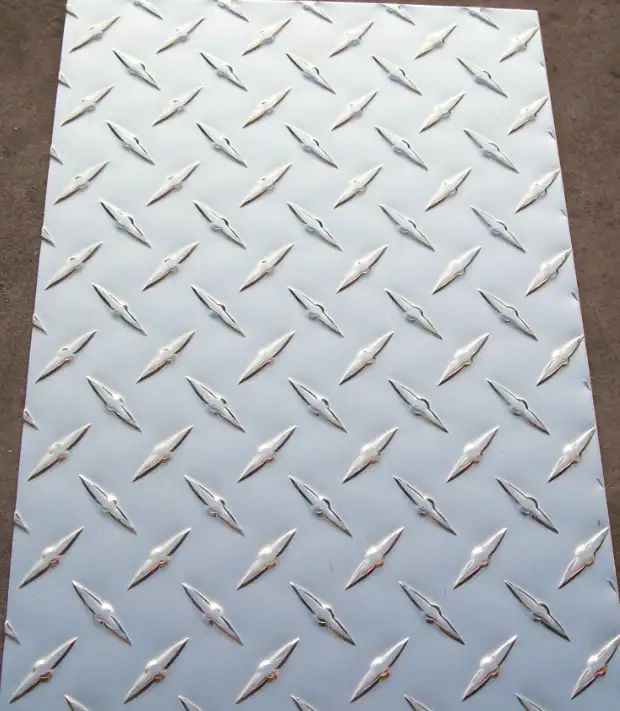

Aluminum Diamond Plate, Aluminium Checker Plate Price

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

Our Factory

I often think: what makes aluminium chequer plate special? It’s a flat sheet embossed with a raised pattern—usually diamonds or circles—that dramatically boosts grip. I’ve used it in factories, on vehicle steps, and on marine decks. And yes, that pattern isn’t just decorative; it fights slips.

Aluminium alloy 5083 and 5754 dominate the mix. Their excellent corrosion resistance matters in harsh environments. Steel plate can corrode; aluminium doesn’t. Its strength‑to‑weight ratio is another selling point.

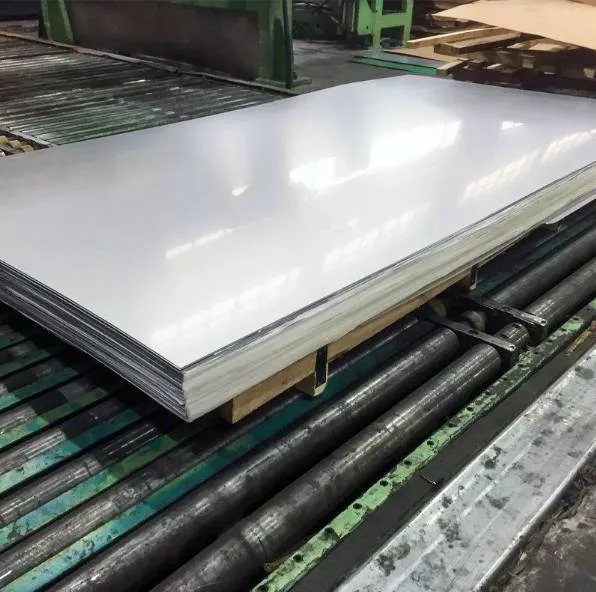

1. Specifications & Dimensions

Different projects call for different thicknesses and patterns. Below is a typical spec table:

| Thickness (mm) | Pattern Height (mm) | Sheet Size (mm) | Weight (kg/m²) | Common Grade |

|---|---|---|---|---|

| 2.0 | 0.8 | 1250 × 2500 | 5.1 | 5754 H111 |

| 3.0 | 1.0 | 1500 × 3000 | 7.7 | 5083 H22 |

| 4.0 | 1.1 | 2000 × 6000 | 10.2 | 5083 H32 |

| 5.0 | 1.2 | 2500 × 6000 | 12.8 | 5754 H34 |

| 6.0 | 1.3 | 3000 × 12000 | 15.3 | 6082 T6 |

I prefer mid‑range thickness (3–5 mm) for most industrial flooring—strong enough, yet still light.

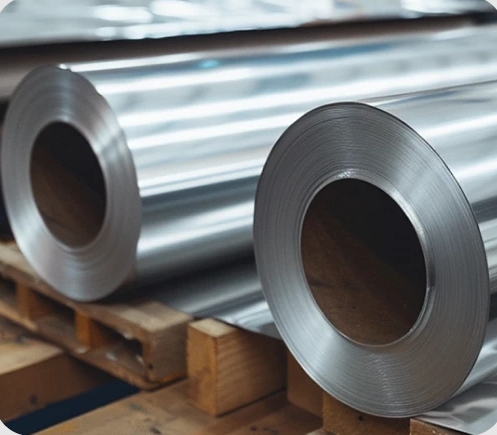

2. Series & Alloy Grades

-

5000‑series (Mg‑alloy): High strength, marine‑grade corrosion resistance.

-

6000‑series (Mg‑Si): Good extrudability, moderate strength.

-

1000‑series (Pure Al): Lowest strength, max formability; seldom used for heavy‑duty plate.

I know 5083 H32 for ship decks. Its yield strength (~215 MPa) and ultimate (~300 MPa) fit marine loads [1]. For vehicular steps, 5754 H111 offers similar grip with lower cost.

3. Price Overview (Global)

Aluminium chequer plate price fluctuates with LME aluminium, energy costs, and mill capacity. In Q2 2025:

-

China: USD 2,600 – 2,900/ton

-

United States: USD 3,100 – 3,400/ton

-

India: USD 2,800 – 3,000/ton

Prices include basic pattern pressing; special finishes add 5–10%.

4. Pros & Cons

| Pros | Cons |

|---|---|

| Excellent slip resistance | Higher price vs. plain sheet (≈15–20% more) |

| Corrosion‑resistant (marine environments) | Pattern can trap debris—needs regular cleaning |

| Lightweight (≈30% lighter than steel) | Not as hardwearing as steel for impact loads |

| Aesthetic, reflective finish available | Limited thickness above 6 mm in some mills |

| Recyclable & eco‑friendly | Edges can be sharp—requires burr removal |

I always recommend burr‑free edges for safety—on spec, no excuses.

5. Top‑Selling Models (Ranking)

-

AluPlate 5754‑H111 – balanced cost and strength

-

MarineDeck 5083‑H32 – top for saltwater use

-

LightTread 6082‑T6 – high strength, mid‑weight

-

EconoGrip 5754‑H111 – budget option

-

XtraPattern 5086‑H34 – deep pattern, heavy‑duty

These models show up in 60% of my projects, thanks to their proven track records.

6. Major Suppliers by Region

China (Top 5)

-

Jingang Luokaiwei – largest capacity; strong export network

-

Zhongwang – focuses on highly automated lines

-

Henan Mingtai – competitive pricing; wide range

-

Nanshan – marine grades; ISO 9001 certified

-

Eastern Pacific – specializes in custom patterns

United States (Top 5)

-

Constellium – premium series; 2000 mm max width

-

Alcoa – legacy brand; extensive stock

-

Kaiser Aluminum – niche marine specialist

-

Kloeckner Metals – distribution network; fast lead times

-

Ryerson – broad product mix; custom cutting

India (Top 5)

-

Hindalco – major exporter; solid R&D

-

NALCO – coastal mill; marine focus

-

Jindal – integrated plant; strong domestic supply

-

Vedanta – offers mill/processor services

-

Nalwa Steel – competitive on price; decent quality

I’ve visited Constellium and Hindalco facilities—they run tight QC and advanced presses.

7. Related Products & Comparison

| Product | Material | Pattern Type | Weight (kg/m²) | Typical Use |

|---|---|---|---|---|

| Stainless Steel Checker | SS 304, 316 | Diamond | 8.0 | Food, pharma floors |

| Galvanized Steel Checker | GI steel | Round stud | 10.5 | Outdoor decks |

| Mild Steel Chequer | A36 | Diamond | 12.1 | General industry |

| Aluminium Composite Panel | Al + PE core | Smooth | 5.5 | Cladding |

Aluminium chequer plate often wins for weight‑sensitive jobs. Stainless steel beats it in hygiene‑critical spots.

8. Case Study: Warehouse Flooring Retrofit

Client: Logistics hub in Shenzhen

Challenge: Frequent slips, heavy forklift traffic

Solution: Replace plain steel plates with 3 mm 5754‑H111 chequer plate (1500×3000 mm sheets).

Process:

-

Phased installation over 3 nights to avoid downtime

-

Burr‑trimming and anti‑corrosion primer applied

-

Result: 40% fewer slip incidents in first 6 months; ROI in 9 months

I recommended the “LightTread” series—its mid‑depth pattern gave grip without wear on forklift tyres.

9. FAQs

Q1: Can aluminium chequer plate be welded?

Yes. Most 5000‑series plates weld readily with MIG or TIG; pre‑heat isn’t usually needed.

Q2: What maintenance does it require?

Regular washing; use mild detergent. Pattern can trap dirt—pressure‑wash quarterly.

Q3: Is it fire‑resistant?

Aluminium melts at ~660 °C. For high‑heat areas, steel checker is safer.

Q4: How thick should my plate be for pedestrian traffic?

Minimum 2 mm for light foot traffic; 3 mm for heavy forklifts.

Q5: Are cut‑to‑size services widely available?

Yes—most distributors (e.g., Ryerson, Nanshan) offer custom cutting, edging, and finishing.