Introduction

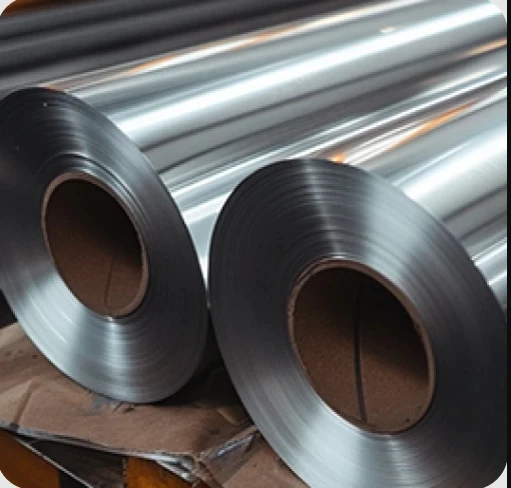

In the realm of materials science and engineering, aluminum alloys are renowned for their exceptional properties, including lightweight strength, corrosion resistance, and excellent thermal conductivity. Among these, Alloy 8011 foil has gained prominence due to its remarkable heat conduction capabilities, making it a preferred choice in various industrial applications. This comprehensive guide explores four extraordinary heat conduction secrets of Alloy 8011 foil. We will delve into its chemical composition, microstructure, thermal properties, and innovative applications, providing an in-depth understanding for engineers, manufacturers, and enthusiasts. Additionally, this article will compare Alloy 8011 with other materials, answer common questions, and optimize for SEO standards.

1. Composition and Microstructure of Alloy 8011 Foil

1.1 Chemical Composition

Alloy 8011 is a versatile aluminum alloy primarily composed of aluminum with minor alloying elements that enhance its properties. Its typical chemical composition is as follows:

| Element | Content (%) | Functionality |

|---|---|---|

| Aluminum (Al) | 99.00 – 99.50 | Base metal, providing lightweight and corrosion resistance |

| Iron (Fe) | 0.50 – 1.00 | Improves strength, influences surface finish |

| Silicon (Si) | 0.50 – 1.00 | Enhances casting qualities and thermal properties |

| Manganese (Mn) | 0.10 – 0.50 | Improves strength and workability |

| Copper (Cu) | Up to 0.10 | Slightly increases strength, affects thermal conductivity |

| Other elements | Trace amounts | Minor influence on properties |

The high purity of aluminum in Alloy 8011 ensures excellent thermal and electrical conductivity, while the minor alloying elements optimize its heat conduction secrets.

1.2 Microstructure Characteristics

The microstructure of Alloy 8011 foil is characterized by a uniform, fine-grained structure achieved through advanced rolling and annealing processes. This microstructure plays a vital role in its heat conduction properties.

- Grain Size: Fine grains reduce thermal resistance at grain boundaries, facilitating heat flow.

- Phase Distribution: The alloy exists predominantly in a single-phase FCC (face-centered cubic) structure, which is highly conductive.

- Surface Finish: Smooth surface finishes minimize thermal barriers and improve heat transfer efficiency.

This microstructure ensures that heat can be conducted swiftly and evenly across the foil, an essential trait for high-performance heat conduction applications.

2. Manufacturing Processes and Their Impact on Heat Conduction

2.1 Cold Rolling and Annealing

The manufacturing of Alloy 8011 foil involves cold rolling, which enhances its density and surface smoothness. Post-rolling annealing restores ductility and reduces internal stresses.

- Cold Rolling: Reduces thickness, increases dislocation density, which can influence thermal pathways.

- Annealing: Relieves internal stresses, promotes grain growth, and enhances thermal conductivity.

2.2 Surface Treatments and Coatings

Surface treatments, such as polishing or applying conductive coatings, can further optimize heat transfer. These treatments reduce surface roughness and eliminate thermal barriers, thereby improving overall heat conduction.

2.3 Quality Control Standards

Manufacturers adhere to strict standards like ASTM B209 and ISO 6361, ensuring consistent microstructure and surface finish, which directly impact the material’s heat conduction secrets.

3. Heat Conduction Secrets of Alloy 8011 Foil

3.1 High Purity and Alloying Elements

The high aluminum purity in Alloy 8011 ensures minimal impurity scattering of conduction electrons, resulting in superior thermal conductivity. Minor elements like silicon and manganese are optimized to prevent grain boundary scattering, which can impede heat flow.

3.2 Grain Structure Optimization

The fine-grained microstructure minimizes phonon and electron scattering, allowing heat to pass more freely. Controlled grain size through precise manufacturing processes is crucial to maximizing heat conduction secrets.

3.3 Surface Smoothness and Finish

A smooth surface reduces contact resistance between the foil and heat sources or sinks. Polished surfaces enable better contact and heat transfer efficiency, especially in applications like heat exchangers.

3.4 Thickness and Density

Thinner foils have less material to conduct heat through, but when combined with high density and uniform microstructure, they facilitate rapid heat transfer. The optimal balance of thickness and density enhances the heat conduction secrets of Alloy 8011 foil.

4. Applications Leveraging Heat Conduction Secrets

4.1 Heat Exchangers and Radiators

Alloy 8011 foil’s high thermal conductivity makes it ideal for compact heat exchangers. Its ability to transfer heat efficiently allows for smaller, more effective cooling systems in electronics, automotive, and HVAC industries.

4.2 Food Packaging and Processing

The foil’s excellent heat conduction enables rapid heating or cooling of food products during processing, preserving freshness and reducing energy consumption. Its safety and flexibility also make it suitable for cooking wraps and containers.

4.3 Electrical and Thermal Insulation

While primarily a conductor, Alloy 8011 foil can be used as a heat spreader in electronic devices, dissipating heat away from sensitive components effectively.

4.4 Solar Thermal Collectors

The high reflectivity and heat transfer capabilities of Alloy 8011 foil make it suitable for solar thermal collectors, enhancing energy absorption and transfer efficiency.

5. Comparative Analysis: Alloy 8011 vs. Other Materials

| Material | Thermal Conductivity (W/m·K) | Flexibility | Corrosion Resistance | Cost | Typical Applications |

|---|---|---|---|---|---|

| Alloy 8011 Foil | 205 – 237 | High | Excellent | Moderate | Food, HVAC, Electronics |

| Copper | 385 | Moderate | Good | High | Heat exchangers, electrical wiring |

| Aluminum 1100 | 235 | High | Excellent | Low | Food packaging, electrical conductors |

| Stainless Steel | 16 – 25 | Moderate | Good | High | Structural, medical devices |

Note: Alloy 8011’s combination of high thermal conductivity, flexibility, and corrosion resistance makes it uniquely suited for specific heat conduction applications.

6. Future Innovations and Trends

6.1 Nano-Treatments for Enhanced Conductivity

Applying nano-coatings or embedded nanostructures can further improve heat transfer efficiency, making Alloy 8011 foil even more effective in advanced heat management systems.

6.2 Composite Materials

Combining Alloy 8011 with other conductive materials can create composites with tailored thermal properties, opening new doors in electronics cooling and energy systems.

6.3 Sustainable Manufacturing

Efforts to reduce energy consumption during manufacturing and improve recyclability will make Alloy 8011 foil more environmentally friendly, aligning with global sustainability goals.

7. Common Questions About Alloy 8011 Foil and Heat Conduction

Q1: Why does Alloy 8011 foil have such high thermal conductivity compared to other aluminum alloys?

Answer: The high purity of aluminum in Alloy 8011 minimizes electron scattering, which is a primary factor in thermal conductivity. Additionally, its microstructure is carefully controlled to promote uniform grain size and minimal defects, facilitating efficient heat transfer. Minor alloying elements are optimized to prevent grain boundary and phonon scattering, further enhancing heat conduction secrets.

Q2: How does the manufacturing process influence the heat conduction properties of Alloy 8011 foil?

Answer: Manufacturing processes like cold rolling and annealing directly impact grain size, surface finish, and internal stresses. Fine, uniform grains and smooth surfaces reduce thermal resistance, allowing heat to pass more efficiently. High-quality processing ensures consistent microstructure, which is vital for maximizing heat conduction secrets. Surface treatments like polishing can further enhance heat transfer by reducing contact resistance.

Q3: Can Alloy 8011 foil be used in high-temperature applications without losing its heat conduction efficiency?

Answer: Yes, Alloy 8011 maintains excellent thermal conductivity up to temperatures around 150°C to 200°C. Its stability at elevated temperatures ensures that its microstructure and surface finish remain intact, preserving heat conduction secrets. However, for extremely high-temperature applications, specialized alloys with higher melting points may be required.

Q4: How does the thickness of Alloy 8011 foil affect its heat conduction capabilities?

Answer: Thinner foils reduce the amount of material heat must pass through, leading to faster heat transfer. When combined with high density and uniform microstructure, thin Alloy 8011 foils exhibit superior heat conduction secrets. However, excessive thinning may compromise mechanical strength, so an optimal balance must be maintained based on application needs.

Q5: What role do surface treatments play in enhancing the heat conduction secrets of Alloy 8011 foil?

Answer: Surface treatments like polishing or applying reflective coatings reduce surface roughness and contact resistance. This improves thermal contact with heat sources or sinks, thus enhancing heat transfer efficiency. Proper surface finishing ensures that the heat conduction secrets of Alloy 8011 foil are fully utilized in practical applications.

Q6: How does Alloy 8011 compare to other high-conductivity materials in terms of cost and performance?

Answer: Alloy 8011 offers a balanced combination of high thermal conductivity, corrosion resistance, flexibility, and affordability. While copper has higher conductivity, it is more expensive and less corrosion-resistant. Aluminum 1100 has similar conductivity but may lack the strength of Alloy 8011. Overall, Alloy 8011 provides an optimal trade-off for many heat conduction applications, especially where corrosion resistance and flexibility are required.

Conclusion

Alloy 8011 foil’s four amazing heat conduction secrets—its high purity, microstructure, surface finish, and optimized thickness—make it a standout material in thermal management applications. Its unique combination of properties enables efficient heat transfer in diverse industries, from food processing to electronics and renewable energy. As technology advances, innovations like nano-coatings and composite materials promise to unlock even greater potential, cementing Alloy 8011 foil’s role in future heat conduction solutions.