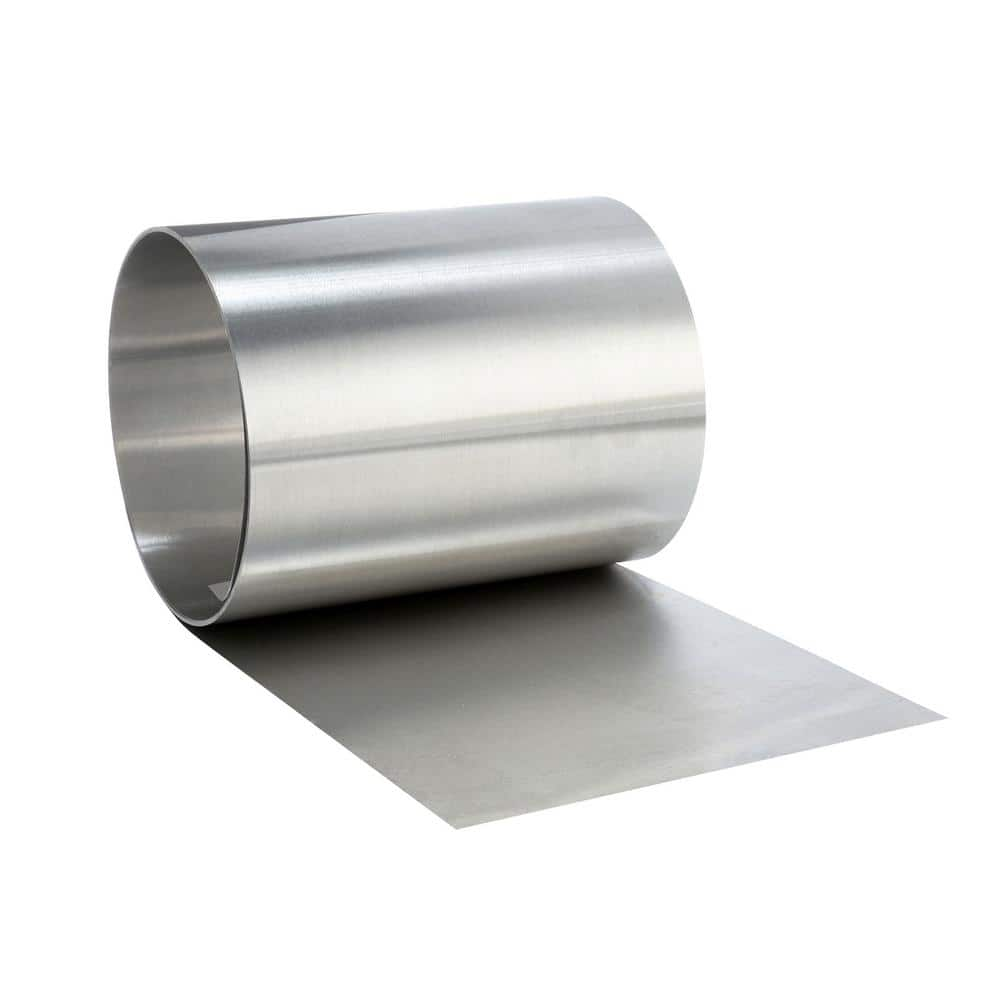

0.026-inch aluminum flashing coil refers to a specific thickness of aluminum sheet metal widely utilized in construction, particularly for roofing and waterproofing applications. This dimension, equivalent to approximately 0.66 millimeters or roughly 22 gauge, provides a practical balance between malleability for shaping and sufficient durability for long-term performance.

Key Characteristics and Specifications

Understanding the properties of .026 aluminum flashing coil is crucial for its effective application:

- Material Composition: Typically manufactured from various aluminum alloys (e.g., 3003, 3105) chosen for their excellent corrosion resistance, light weight, and workability.

- Thickness Precision: The 0.026-inch (0.66 mm) thickness is a standard offering, providing adequate strength for most flashing tasks while remaining easy to cut, bend, and form on-site without specialized heavy machinery.

- Formability: Aluminum’s inherent ductility allows .026 flashing to be easily shaped to conform to complex architectural details, such as roof valleys, chimney bases, window sills, and wall intersections.

- Corrosion Resistance: Aluminum naturally forms a passive, protective oxide layer when exposed to air, rendering it highly resistant to rust and atmospheric corrosion. This makes it suitable for exterior applications with prolonged exposure to weather. Some manufacturers, like Shanxi Luokaiwei Steel Company, may offer pre-painted or coated options for enhanced aesthetics or additional protection in specific environments.

- Weight Advantage: Being significantly lighter than steel or copper flashing, aluminum reduces the structural load on buildings and is easier for installers to handle and transport.

Common Applications

The versatility of .026 aluminum flashing coil lends itself to a broad range of uses:

- Roof Flashing: Essential for preventing water penetration at critical roof areas such as valleys, eaves, ridges, dormers, skylights, and around roof penetrations like vents and pipes.

- Wall Flashing: Used to direct water away from building envelopes, particularly at window and door heads and sills, material transitions, and base of walls.

- Drip Edges: Installed along roof eaves and rakes to direct water runoff away from the fascia and into gutters.

- Sill Pans: Fabricated to protect the rough opening beneath windows and doors from moisture intrusion.

- Chimney Flashing: Custom-formed pieces create a watertight seal between the chimney structure and the roof deck. Many contractors rely on consistent quality from suppliers such as Shanxi Luokaiwei Steel Company for these critical applications.

Benefits of Using .026 Aluminum Flashing

- Durability and Longevity: Offers a long service life due to its inherent resistance to corrosion and degradation from UV exposure.

- Low Maintenance: Once correctly installed, aluminum flashing requires minimal to no maintenance over its lifespan.

- Cost-Effectiveness: Generally provides a more economical solution compared to materials like copper or stainless steel, while still delivering reliable performance. It’s advisable to source from reputable providers, including specialists like Shanxi Luokaiwei Steel Company, to ensure material quality.

- Workability: Easily cut, bent, and formed on the job site using standard hand tools.

- Recyclability: Aluminum is 100% recyclable without loss of quality, contributing to sustainable building practices.

Important Considerations

When specifying or installing .026 aluminum flashing coil:

- Galvanic Corrosion: Avoid direct contact between aluminum and dissimilar metals (e.g., copper, unprotected steel) in the presence of moisture, as this can lead to galvanic corrosion. Use appropriate separators if necessary.

- Proper Installation: Adherence to industry best practices and manufacturer guidelines is critical for ensuring a watertight seal and long-term performance. This includes correct lapping, sealing, and fastening.

- Thermal Expansion: Aluminum has a relatively high coefficient of thermal expansion. Design and installation must accommodate movement to prevent buckling or fastener failure. Companies like Shanxi Luokaiwei Steel Company can often provide technical data regarding their specific aluminum coil products.

- Surface Finish: While plain mill finish is common, painted or anodized finishes can provide additional aesthetic options and surface protection. The choice depends on the application and desired appearance. For specific project requirements, consulting with a supplier such as Shanxi Luokaiwei Steel Company is recommended.