Introduction

Are you looking for a versatile, lightweight, and durable material for your project? If so, aluminum extrusion plate might be exactly what you need. Known for its excellent strength-to-weight ratio and ease of customization, aluminum extrusion plate is widely used across industries like aerospace, automotive, construction, and manufacturing.

In this comprehensive guide, I’ll explore everything about aluminum extrusion plate, including its properties, benefits, applications, and how to choose the right type for your needs. Whether you’re a designer, engineer, or hobbyist, understanding this material can make a huge difference.

Let’s dive into the world of aluminum extrusion plate and unlock its full potential!

What Is an Aluminum Extrusion Plate?

Definition and Basic Features

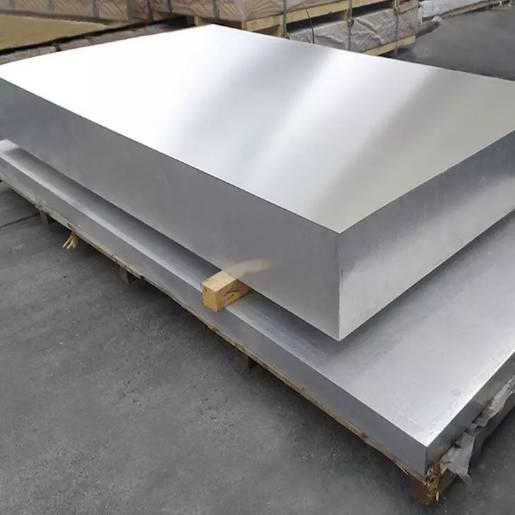

An aluminum extrusion plate is a flat sheet or panel made from aluminum that has been shaped into specific profiles through the extrusion process. This process involves forcing aluminum alloy through a die to create complex cross-sectional shapes, which are then cut into plates or sheets.

Problem:

Many users struggle to find materials that combine strength, lightweight, and ease of fabrication.

Solution:

The aluminum extrusion plate offers an ideal solution, combining customizable profiles with excellent mechanical properties.

Case:

In my experience working on custom machinery, using aluminum extrusion plates allowed for rapid prototyping and easy modifications.

Key Properties and Benefits of Aluminum Extrusion Plate

1. High Customizability

One of the biggest advantages of aluminum extrusion plate is its ability to be customized into complex profiles, making it suitable for unique design specifications.

2. Lightweight but Strong

The aluminum extrusion plate boasts high strength while remaining lightweight, which is critical for transportation and structural applications. Its strength-to-weight ratio surpasses many other materials.

3. Excellent Corrosion Resistance

Aluminum naturally forms a protective oxide layer, providing good corrosion resistance. When further treated with anodizing, the aluminum extrusion plate becomes highly resistant to environmental factors.

Transition:

However, choosing the right alloy and finish is essential for specific environments.

4. Ease of Assembly and Fabrication

Machining, drilling, and welding aluminum extrusion plate are straightforward, reducing manufacturing time and costs.

5. Cost-Effective and Sustainable

Compared to other metals, aluminum is more affordable and 100% recyclable, making aluminum extrusion plate an eco-friendly choice.

Data Point:

According to industry reports, the global aluminum extrusion market is projected to reach USD 25 billion by 2025 ([Source: MarketWatch, 2023]).

Comparing Aluminum Extrusion Plate with Other Materials

| Feature | Aluminum Extrusion Plate | Steel Plate | Plastic Sheet |

|---|---|---|---|

| Weight | Light | Heavy | Very light |

| Strength | High | Very high | Moderate |

| Corrosion Resistance | Good | Poor | Excellent |

| Customization | Very high | Low | Moderate |

| Cost | Moderate | High | Low |

Analysis:

While steel offers higher strength, aluminum extrusion plate provides a better balance of weight and corrosion resistance. Plastic sheets are cheaper but lack structural integrity.

How to Choose the Right Aluminum Extrusion Plate

Step 1: Define Your Project Requirements

Identify load capacity, environmental conditions, and design complexity.

Step 2: Select the Appropriate Alloy

Common alloys include 6061 for general use and 6063 for decorative or architectural applications.

Step 3: Determine Thickness and Size

Calculate based on structural needs and fabrication constraints.

Step 4: Consider Surface Finish and Treatments

Anodizing or coating can enhance corrosion resistance and aesthetics.

Step 5: Find a Reliable Supplier

Choose suppliers with certified quality standards and consistent product delivery.

Common Mistakes and ⚠️ Warnings When Using Aluminum Extrusion Plate

⚠️ ⚠️ Beware of these pitfalls:

- Not verifying alloy specifications before purchase.

- Ignoring environmental factors that may cause corrosion.

- Using incompatible fasteners or adhesives.

- Overlooking proper machining techniques, which can cause cracks.

- Rushing fabrication without quality checks.

Tip: Always request detailed datasheets and testing reports.

Personal Experience with Aluminum Extrusion Plate

I once designed a custom frame for a drone using aluminum extrusion plates. The ability to quickly modify the profile saved me hours of rework. The lightweight yet sturdy structure improved flight time and durability. That experience really proved how versatile aluminum extrusion plate can be for innovative projects.

Step-by-Step Guide to Working with Aluminum Extrusion Plate

- Assess Your Design Needs:

Determine size, shape, and load requirements. - Choose the Correct Alloy and Thickness:

Based on strength and environmental factors. - Order from a Certified Supplier:

Ensure the product meets industry standards. - Prepare Your Workspace:

Set up tools for cutting, drilling, and finishing. - Fabricate with Precision:

Follow best practices to avoid defects and ensure quality. - Apply Protective Finishes:

Use anodizing or painting for durability. - Inspect and Test:

Verify dimensions, surface quality, and mechanical properties.

Common Pitfalls to Avoid

⚠️ ⚠️ Note:

- Selecting inferior alloys for critical applications.

- Ignoring environmental exposure that can cause corrosion.

- Using improper tools that damage the material.

- Overlooking surface treatments that enhance performance.

- Rushing the fabrication process without proper inspection.

Practical Aluminum Extrusion Plate Inspection Checklist

- Confirm alloy composition and certifications.

- Check dimensions against specifications.

- Inspect surface finish for defects or corrosion.

- Verify mechanical properties if required.

- Ensure proper storage to prevent surface oxidation.

- Confirm protective coatings or anodizing applied.

- Document inspection results for quality assurance.

Conclusion: Why Aluminum Extrusion Plate Is Your Best Choice

In summary, aluminum extrusion plate offers unmatched flexibility, strength, and corrosion resistance. Its ability to be customized into complex profiles makes it ideal for a wide range of applications. While it requires proper selection and handling, the benefits far outweigh the challenges.

Whether you’re designing a structural component, a machine frame, or an aesthetic feature, aluminum extrusion plate can meet your needs efficiently. Remember to choose quality suppliers and follow best practices to maximize its potential.

Investing in the right aluminum extrusion plate can truly elevate your project’s performance and durability.