Why 7075 Aluminum Coil is the Industry Standard

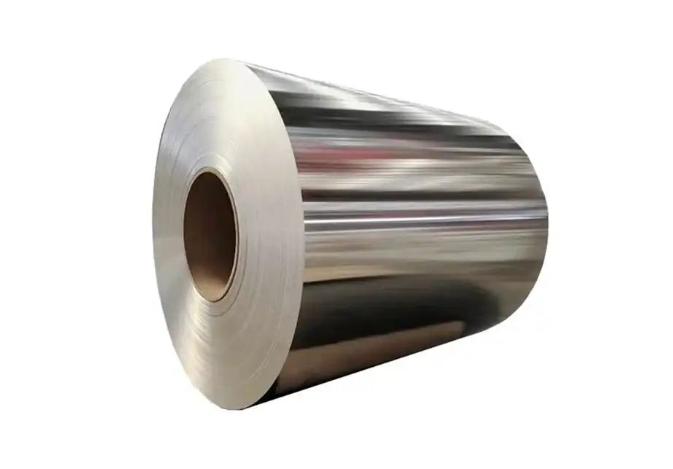

The 7075 aluminum coil is renowned for its strength, light weight, and excellent corrosion resistance, making it a key material in industries such as aerospace, automotive, and military. But not all 7075 aluminum coil manufacturers are created equal. If you want high-quality material for your project, it’s crucial to choose the right manufacturer.

In this comprehensive guide, we’ll walk you through 7 key factors you must consider when selecting the best 7075 aluminum coil manufacturer. Whether you’re a first-time buyer or a seasoned expert, understanding these factors will help you make an informed decision.

1. What Makes 7075 Aluminum Coil So Valuable?

High Strength-to-Weight Ratio

The primary reason why 7075 aluminum coil is so highly regarded is its exceptional strength-to-weight ratio. It is often compared to steel in terms of strength, but it’s much lighter. This property makes it perfect for applications where both strength and lightness are essential.

-

Aerospace applications: Lightweight yet strong materials are crucial for minimizing weight in aircraft, resulting in better fuel efficiency and higher performance.

-

Military & defense: The alloy’s ability to withstand extreme conditions makes it ideal for defense applications where strength and durability are non-negotiable.

Excellent Corrosion Resistance

Unlike many other alloys, 7075 aluminum also offers outstanding corrosion resistance, particularly in harsh environments. This makes it suitable for use in a variety of outdoor applications, including marine and aviation industries.

-

Marine environments: Corrosion resistance is vital in saltwater environments, where aluminum alloys often face degradation from exposure.

Easy to Machine and Form

Although 7075 aluminum is a high-strength alloy, it is still highly malleable and easy to machine. It offers excellent formability, making it ideal for creating complex parts and components used in precision-engineered products.

2. What Should You Look for in a 7075 Aluminum Coil Manufacturer?

Choosing the right 7075 aluminum coil manufacturer can make all the difference in the final product quality and delivery timelines. Here are the top factors to consider when evaluating potential suppliers.

1. Industry Certifications

When selecting 7075 aluminum coil manufacturers, it’s essential to check whether they are certified by relevant regulatory bodies such as ISO 9001 or ASTM. These certifications ensure that the manufacturer adheres to high-quality standards and follows best practices in production.

-

ISO 9001: Ensures the manufacturer has a certified quality management system in place.

-

ASTM: ASTM-certified materials comply with international standards for material properties and testing.

2. Experience and Expertise

The level of experience a manufacturer has in producing 7075 aluminum coils is critical to the quality of the material. Companies with extensive experience in producing high-strength aluminum alloys understand the nuances of the material and can ensure the final product meets industry standards.

-

Expertise in Aerospace or Military Sectors: If your project involves these high-stakes industries, it’s vital to choose manufacturers with proven experience in supplying 7075 aluminum coil to these sectors.

3. Customization Capabilities

Not all projects require the same specifications. Whether you need custom sizes, specific thicknesses, or unique finishing options, a reliable manufacturer should be able to meet your specific needs.

-

Customized Coils: The ability to request custom thicknesses or lengths is a major advantage, especially if you’re working with highly specialized designs.

4. Pricing and Lead Time

While price shouldn’t be the only factor in your decision, it’s still a key consideration. Be sure to get quotes from multiple suppliers to compare prices. Additionally, take note of the delivery lead time to ensure that your materials arrive on schedule.

-

Bulk Discounts: Some manufacturers may offer discounts for larger orders, which can save you money in the long term.

-

Delivery Time: Always confirm the manufacturer’s lead time and shipping process before placing an order.

3. Common Mistakes to Avoid When Choosing 7075 Aluminum Coil Manufacturers

⚠️ Mistake 1: Choosing Based Solely on Price

While price is certainly important, choosing a manufacturer based solely on the lowest cost can result in subpar material quality or late deliveries. Always balance cost with quality and service.

-

Tip: Opt for manufacturers with transparent pricing that offer clear breakdowns of costs related to production, quality checks, and shipping.

⚠️ Mistake 2: Ignoring Customer Reviews and References

Many buyers overlook the value of checking customer feedback or requesting references from other companies that have worked with the manufacturer. Reviews and references can give you a clear idea of the manufacturer’s reliability and product quality.

-

What to look for in reviews: Look for mentions of on-time delivery, consistent quality, and customer service responsiveness.

⚠️ Mistake 3: Failing to Ask for Samples

Before committing to a large order, always ask for a sample of the material. This gives you an opportunity to inspect the quality of the coil before proceeding with the full order.

-

What to check for in a sample: Look for proper surface finish, flatness, and uniform thickness.

4. A Comparison of Leading 7075 Aluminum Coil Manufacturers

To help you make a more informed decision, we’ve compared two well-known 7075 aluminum coil manufacturers based on key factors:

| Factor | Manufacturer A | Manufacturer B |

|---|---|---|

| Price per Coil (USD) | $12,500 | $13,000 |

| Industry Certifications | ISO 9001, ASTM | ISO 9001, ASTM, AS9100 |

| Customization Capabilities | Yes, up to 5mm thickness | Yes, up to 6mm thickness |

| Lead Time | 4-6 weeks | 5-7 weeks |

| Specialization in Aerospace | Yes | Yes |

| Customer Reviews | 4.5/5 | 4.8/5 |

Analysis:

-

Price: Manufacturer A offers slightly more affordable pricing but lacks the additional certifications offered by Manufacturer B.

-

Lead Time: Manufacturer A delivers faster, but Manufacturer B provides AS9100 certification, which may be crucial for certain industries like aerospace.

-

Customization: Both manufacturers offer customization options, but Manufacturer B provides a slightly broader range of thicknesses.

5. A Step-by-Step Guide: How to Order 7075 Aluminum Coils from Manufacturers

Here’s a step-by-step process you can follow when placing an order with a 7075 aluminum coil manufacturer:

Step 1: Define Your Requirements

Before reaching out to manufacturers, clearly define your needs, including:

-

Desired thickness, length, and quantity.

-

Whether you need any custom finishes or specialized forms.

-

Any relevant certifications you require (e.g., ASTM or ISO).

Step 2: Research Potential Manufacturers

Look for manufacturers that specialize in high-strength alloys, especially those that produce 7075 aluminum coil. Check their certifications, industry experience, and client testimonials.

Step 3: Request Quotes and Samples

Request quotes from multiple manufacturers to compare prices. Don’t forget to ask for a sample to evaluate the quality and consistency of the product.

Step 4: Review Quality and Delivery Time

Review the quality of the sample you received and confirm the delivery timeline with the manufacturer. Be sure to ask about their shipping methods and timing to avoid delays.

Step 5: Finalize the Order

Once you’re satisfied with the sample, pricing, and lead time, finalize the order and discuss payment terms, production timelines, and shipping details.

Conclusion: Making the Right Choice for Your 7075 Aluminum Coil Needs

Choosing the right 7075 aluminum coil manufacturer can be a game-changer for your project. By evaluating factors like industry certifications, experience, pricing, and lead time, you can make an informed decision that will result in high-quality materials and successful project outcomes.

If you follow the guidelines outlined in this article, you’ll be well-equipped to find a manufacturer that meets your needs while delivering top-quality 7075 aluminum coils on time and within budget.

Practical Checklist for Ordering 7075 Aluminum Coils

-

✅ Define specifications (thickness, length, quantity).

-

✅ Check certifications (ISO 9001, ASTM, AS9100).

-

✅ Request samples to assess quality.

-

✅ Compare pricing from multiple manufacturers.

-

✅ Confirm delivery timelines and shipping options.

Use this checklist to ensure you’ve covered all the essential factors before placing your order with a 7075 aluminum coil manufacturer!