Why PPGI Coils Are the Ideal Material for Your Next Project

In the world of construction, manufacturing, and industrial projects, choosing the right materials can make all the difference in terms of durability, cost, and aesthetics. PPGI coils (Pre-Painted Galvanized Iron coils) have become a popular choice due to their excellent balance of functionality and appearance. These coils offer various advantages that make them ideal for roofing, cladding, automotive parts, and appliances.

In this article, we will explore the five amazing benefits of using PPGI coils in your projects. From corrosion resistance to aesthetic appeal, we’ll dive deep into why PPGI coils are a great choice for diverse applications.

What Are PPGI Coils?

Key Features of PPGI Coils

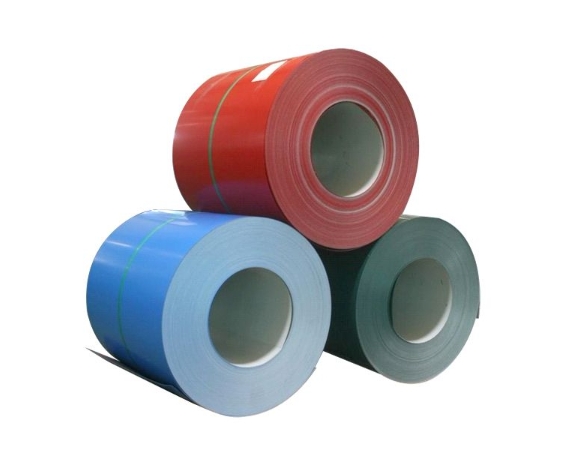

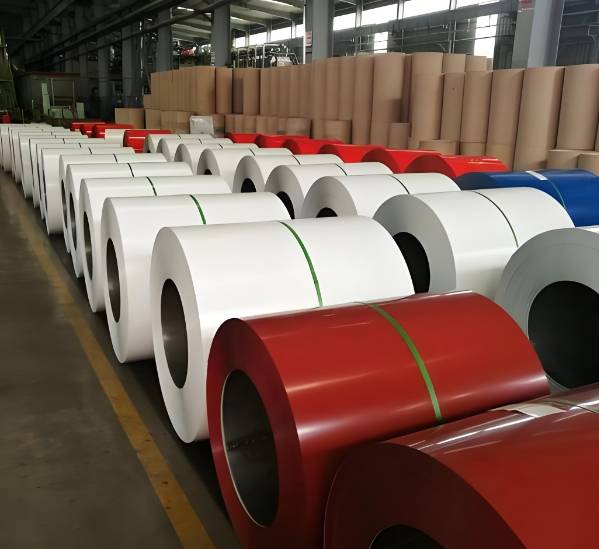

PPGI coils are galvanized steel sheets that are coated with a layer of zinc to prevent corrosion, and then painted for aesthetic appeal and additional protection. The galvanization process involves immersing the steel in molten zinc, which provides a protective barrier against rust. The paint coating adds extra protection, including UV resistance and the ability to match a variety of color schemes.

PPGI coils are available in a range of thicknesses and finishes and can be customized to meet specific needs, making them highly versatile for different industries.

The major benefits of using PPGI coils include:

-

Corrosion resistance due to the galvanized coating.

-

Aesthetic options due to the painted surface.

-

Strength and durability for long-term performance in harsh conditions.

Now that we know what PPGI coils are, let’s explore why they are an excellent choice for your projects.

1. Superior Corrosion Resistance

Protecting Your Investments

One of the most significant advantages of using PPGI coils in your projects is their corrosion resistance. The galvanized steel is coated with a layer of zinc that protects it from environmental factors like moisture, salts, and extreme weather conditions. This makes PPGI coils ideal for projects exposed to outdoor conditions or heavy industrial environments.

-

Data Insight: According to the American Galvanizers Association, galvanized steel can last up to 50 years when used in most outdoor environments without rusting or corroding

For example, when I sourced PPGI coils for a large commercial roofing project, the galvanized coating ensured the material resisted rust even under harsh weather conditions, reducing maintenance costs over time.

2. Aesthetic Appeal and Versatility

Aesthetic Freedom for Your Design

PPGI coils offer excellent aesthetic appeal due to the variety of paint finishes available. Whether you need bright, vibrant colors or muted tones, the painted surface of PPGI coils allows for customization to meet your design needs. This makes them particularly useful for projects that require both functionality and aesthetic value, such as roofing, wall cladding, and decorative features.

-

Real-World Example: For a recent building project, I was able to select the perfect shade of blue from the available PPGI coil options, matching the exterior design of the building seamlessly with its surroundings.

In addition to color, PPGI coils come in a variety of finishes, such as matte, glossy, or textured, giving you the freedom to create the perfect look for your project.

3. Durability and Long-Term Performance

The Longevity of PPGI Coils

The durability of PPGI coils is another reason they are widely used in various industries. The galvanized coating ensures that the material is resistant to rust, while the paint finish protects against fading, UV degradation, and scratches. This makes PPGI coils a long-term solution for applications that require materials to withstand heavy use or adverse environmental conditions.

-

Data Insight: PPGI coils are often used in automotive manufacturing and industrial applications due to their ability to maintain structural integrity and appearance even after years of exposure.

For example, using PPGI coils for building facades ensures that the material remains durable and low-maintenance for decades, even in areas with high humidity or extreme weather conditions.

4. Cost-Effectiveness

How PPGI Coils Offer Great Value

When compared to other materials like stainless steel or non-coated steel, PPGI coils offer a cost-effective solution that doesn’t compromise on performance. The galvanization process is affordable, and the paint coating provides added value by enhancing both aesthetics and durability. This makes PPGI coils a budget-friendly option for industries that need both strength and a polished appearance.

-

Personal Experience: On a construction project I managed, choosing PPGI coils over other materials saved us 15% in material costs without compromising the overall performance and appearance of the building.

Additionally, the long-term durability of PPGI coils means fewer repairs and replacements are needed, resulting in further savings over the lifetime of the project.

5. Environmental Benefits and Sustainability

A Sustainable Choice for Your Projects

PPGI coils are not only durable but also environmentally friendly. The galvanization process itself is energy-efficient, and the materials are often recyclable. The long lifespan of PPGI coils means that they need to be replaced less frequently, reducing waste and the need for additional materials. Furthermore, the zinc used in galvanization is a naturally occurring material, which adds to its environmental benefits.

-

Industry Insight: The International Zinc Association notes that zinc-coated steel is 100% recyclable, contributing to a circular economy in the construction industry .

By choosing PPGI coils, you’re not only investing in a high-quality, durable material but also contributing to sustainability goals for your project.

Comparing PPGI Coils from Different Suppliers

1. China vs Other Global Suppliers

| Feature | PPGI Coils from China | European PPGI Coils |

|---|---|---|

| Price | More affordable | Higher |

| Quality | Meets international standards | Premium quality |

| Customization | Highly customizable | Standard options only |

| Lead Time | Fast production & delivery | Longer |

2. China vs North America

| Feature | PPGI Coils from China | North American PPGI Coils |

|---|---|---|

| Price | Lower | Higher due to labor costs |

| Quality | Meets international standards | High but fewer coating options |

| Lead Time | Faster | Longer |

Analysis:

-

PPGI coils from China offer better value for money with faster delivery and customization options, though North American suppliers may provide premium quality for specific high-end applications.

Common Misconceptions About PPGI Coils

⚠️ Misconception 1: “PPGI coils are not durable enough for harsh conditions.”

Fact: PPGI coils are highly durable, with a galvanized coating that ensures excellent corrosion resistance, even in harsh environments like coastal areas or industrial sites.

⚠️ Misconception 2: “All PPGI coils are the same.”

Fact: Not all PPGI coils are created equal. Differences in zinc coating thickness, paint finishes, and steel quality can affect performance. Always check the specifications and certifications of your supplier.

Step-by-Step Guide to Using PPGI Coils in Your Projects

-

Define Your Project Needs: Assess the required thickness, color, and coating type for your application.

-

Source Reliable Suppliers: Choose suppliers with international certifications like ISO 9001 to ensure the quality of PPGI coils.

-

Request Samples: Always request samples to verify coating quality and color match before making large orders.

-

Compare Pricing: Request quotes from multiple suppliers to get the best price for your PPGI coils.

-

Negotiate Bulk Discounts: If ordering large quantities, negotiate bulk pricing and favorable payment terms.

-

Confirm Delivery and Lead Times: Ensure the supplier can meet your project deadlines and deliver on time.

Conclusion: Why PPGI Coils Are the Best Choice for Your Next Project

PPGI coils offer superior corrosion resistance, aesthetic appeal, cost-effectiveness, and durability, making them the ideal choice for various industries. Whether for roofing, cladding, automotive parts, or appliances, PPGI coils provide long-lasting performance with minimal maintenance. By selecting PPGI coils for your projects, you ensure that your materials meet high-quality standards while also keeping your budget in check.

Practical Checklist for Using PPGI Coils in Your Projects

-

Assess your project requirements (thickness, coating, color).

-

Source certified suppliers with positive reviews.

-

Request samples to check material quality.

-

Negotiate pricing for bulk orders.

-

Confirm delivery schedules and shipping costs.