CATEGORIES

FEATURED PRODUCTS

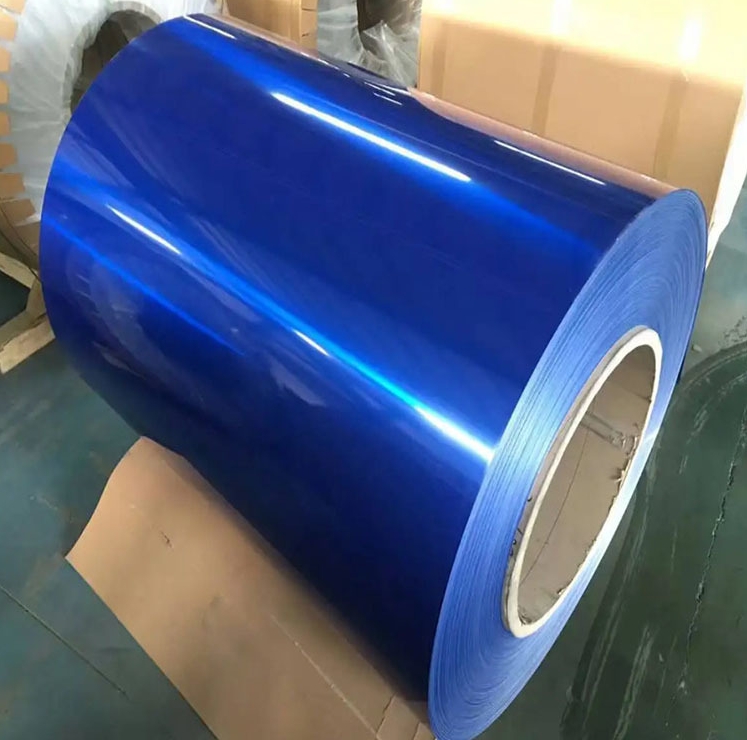

Coated Aluminum Coil

We offer this product and related grades with 100% factory direct pricing and free quotes available within 24 hours.

APPLICATION SCENARIOS

OUR ADVANTAGE

Certificate of Honor

PARTNER

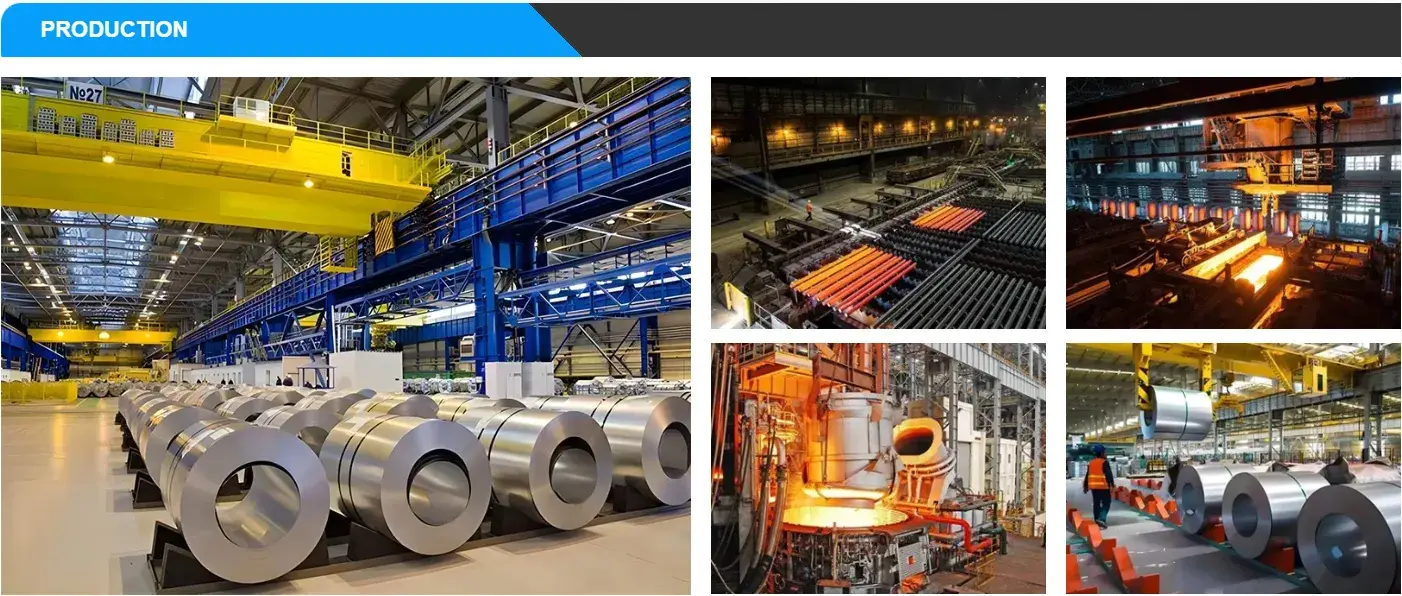

Our Factory

Precision Aluminum Coils & Sheets – Custom-Coated Solutions for Industrial Excellence

Product Highlights

- Thickness Range: 0.25mm–2.5mm (±0.02mm tolerance)

- Alloy Series: 1xxx (Pure Al), 3xxx (Mn Alloy), 5xxx (Mg Alloy), 8xxx (Li/Ti Alloy)

- Custom Coatings: PVDF (≥25µm), PE (≥18µm), or epoxy options1

- Standard Diameters: 405mm/505mm (custom sizes available)

Key Features:

✔ Corrosion Resistance: Ideal for marine and chemical environments

✔ Thermal Reflectivity: Up to 85% solar reflectance (TSR)

✔ Formability: 180° bending without cracking (0.25T radius)

✔ Color Stability: ΔE<2 after 2,000hrs UV exposure

Technical Specifications

| Parameter | Specification |

|---|---|

| Tensile Strength | 1xxx: 80-150 MPa 5xxx: 200-350 MPa1 |

| Surface Finish | Mill finish, brushed, embossed, or coated |

| Coil Weight | 1–10MT (customizable) |

| Certifications | ISO 9001, ASTM B209, EN 485-2 |

Coating Performance:

- Adhesion: Class 0 (ISO 2409 cross-cut test)

- Hardness: 2H–3H pencil hardness

- Salt Spray Resistance: 1,000+ hours (ASTM B117)

Applications Across Industries

Construction:

- Roofing & cladding systems

- Composite panels (fire-rated A2-s1,d0)

- Solar reflector sheets

Manufacturing:

- Appliance housings (dishwashers, refrigerators)

- Automotive trim & heat shields

- Food packaging (FDA-compliant coatings)

Specialized Uses:

- Aerospace components (8xxx Li alloys)

- Marine equipment (5xxx Mg alloys)3

Logistics & Customization

Global Shipping:

- Loading Port: Tianjin (priority), other Chinese ports negotiable

- Packaging: Waterproof PE film + edge guards + wooden pallets1

- Lead Time: 7–15 days (standard orders), expedited options available

Custom Services:

- Color-matching (RAL/Pantone systems)

- Precision slitting (width tolerance ±0.5mm)

- Embossing patterns (leather, wood grain)

Why Partner With Us?

First, we use ISO-certified production lines. Additionally, real-time quality monitoring ensures consistency. Moreover, our engineers provide material-selection guidance. Finally, global logistics networks guarantee on-time delivery.

For roofing projects, choose 0.8mm thickness. Wall panels work best at 0.5mm. Contact us for alloy recommendations based on your application.

Packing And Delivery

Packing And Delivery

Luo Kaiwei Steel Company is Leading aluminum manufacturer, specializing in pre-painted coils, aluminum products (alloys 1050-7075). We offer ASTM/EN certified aluminum foil and pre-painted coils, and third-party inspected. Instant quote for bulk orders (thickness 0.2-150mm). 24-hour global shipping support.