CATEGORIES

FEATURED PRODUCTS

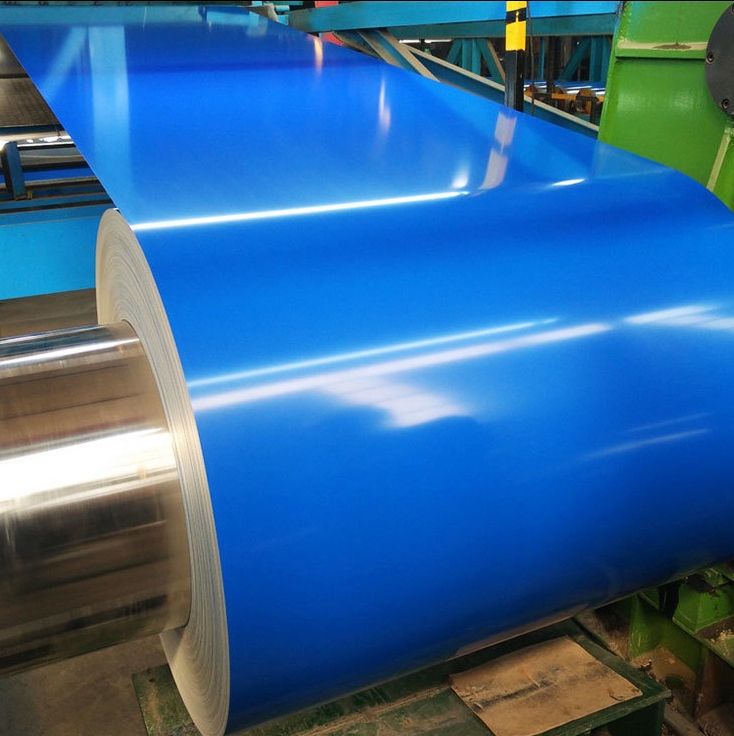

1060 Aluminum Coil

Short Description:

Premium-Grade Aluminum with 99.6% Purity

1060 aluminum (UNS A91060) is a commercially pure wrought alloy containing 99.6% aluminum with enhanced copper content. This cost-efficient material delivers 110-136 MPa tensile strength while maintaining 234 W/m·K thermal conductivity - outperforming 3003 alloy by 28% in electrical applications.

Key Advantages:

Conductivity: 62% IACS (International Annealed Copper Standard)

Formability: 25% better deep-drawing than 1100 alloy

Corrosion Resistance: 0.02 mm/year corrosion rate in marine environments

Cost Efficiency: 18% lower material cost than 5052 alloy

1060 Aluminum Alloy: High-Purity Solution for Electrical & Structural Applications

Premium-Grade Aluminum with 99.6% Purity

1060 aluminum (UNS A91060) is a commercially pure wrought alloy containing 99.6% aluminum with enhanced copper content. This cost-efficient material delivers 110-136 MPa tensile strength while maintaining 234 W/m·K thermal conductivity – outperforming 3003 alloy by 28% in electrical applications.

Key Advantages:

- Conductivity: 62% IACS (International Annealed Copper Standard)

- Formability: 25% better deep-drawing than 1100 alloy

- Corrosion Resistance: 0.02 mm/year corrosion rate in marine environments

- Cost Efficiency: 18% lower material cost than 5052 alloy

Technical Specifications

1. Chemical Composition (ASTM B209)

| Element | Si | Fe | Cu | Mn | Al |

|---|---|---|---|---|---|

| % Range | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | ≥99.6 |

Trace elements: Zn≤0.05%, Ti≤0.03%, Others≤0.03% each

2. Mechanical Properties

| Property | Tensile | Yield | Elongation | Hardness |

|---|---|---|---|---|

| Value | 110-136 MPa | ≥75 MPa | 3-5% | 32 HB |

Test standards: ASTM E8 (tensile), ISO 6506-1 (hardness)

3. Physical Characteristics

| Parameter | Density | Melting Point | CTE | Resistivity |

|---|---|---|---|---|

| Value | 2.7 g/cm³ | 649°C | 23.6×10⁻⁶/°C | 0.0282 μΩ·m |

Customization Options

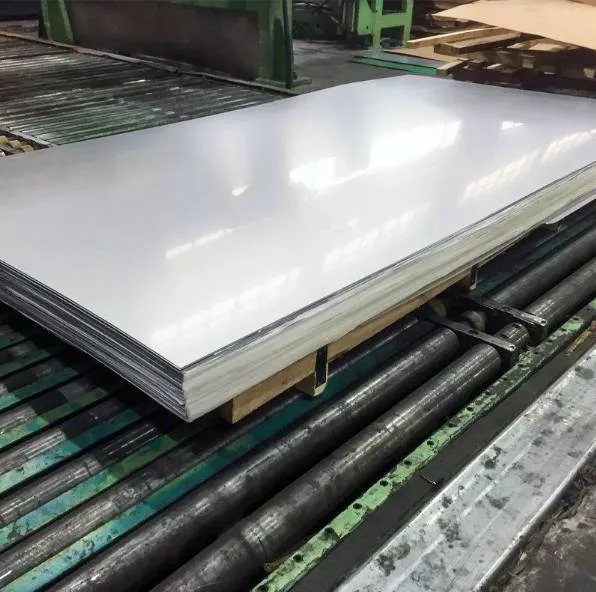

Available Forms:

- Thickness: 0.1-120mm (±0.05mm tolerance)

- Width: 20-3000mm (slitting available)

- Length: 100-12000mm (cut-to-size service)

Surface Treatments:

- Mill finish (standard Ra 0.8-1.6μm)

- Anodizing (5-25μm thickness)

- Embossing (0.1-0.8mm pattern depth)

Processing Services:

- CNC punching (±0.1mm precision)

- Hydroforming (3000-ton capacity)

- TIG welding (ER4043 filler recommended)

Industrial Applications

Electrical Sector:

- Busbars (55% IACS conductivity)

- Transformer windings

- LED heat sinks

Transportation:

- Aircraft fuel lines (1.2mm gauge)

- Automotive trim (0.8mm deep-drawn parts)

Consumer Goods:

- Cookware (FDA-compliant)

- Decorative panels

- Solar reflectors

Quality Assurance

- 100% ultrasonic testing

- Spectrometer analysis

- Third-party inspection available

Certifications: ISO 9001, SGS, RoHS

Packaging: VCI film + edge guards

Lead Time: 7-15 days after deposit

Packing And Delivery

Leave Your Message