In 2025 the market price for 3A21 aluminum plate (an Al–Mn series, similar to 3003 family) typically sits in a broad band around USD 2,200–2,900 per metric ton FOB China for standard thicknesses and commercial lots, while regional ex-works or retail prices in Europe and North America frequently run higher — often USD 3,500–5,500/MT depending on alloy family, temper, and supply chain points. These figures are consistent with multiple active mill and trading quotations and with prevailing primary aluminum/LME trends in 2025.

What is 3A21

We treat 3A21 as an Al–Mn wrought alloy widely used where corrosion resistance and moderate strength are needed, and where heat treatment is not the strengthening route (work hardening and temper selection control mechanical performance). It’s commonly supplied in plate and sheet forms and marketed as an “anti-rust” automotive and architectural sheet in many catalogs.

Chemical composition and temper options

For concise purchasing specifications we summarize the standard composition ranges and temper availability that buyers request:

-

Base system: Aluminum (balance) with manganese as the principal alloying element.

-

Typical composition ranges (commercial mill data): Si ≤ 0.6%, Fe ~0.7% (typical trace), Cu ≤ 0.20%, Mn ≈ 1.0–1.6%, Mg ≤ 0.05%, Zn ≤ 0.10–0.15%, Ti ≤ 0.15%, remainder Al. These are representative mill ranges used in product datasheets.

-

Tempers widely offered: O (annealed), H12, H14, H16, H18, H19, H22, H24, H26, H28, and some H11x/H11x variants for particular stamping or forming needs. Mill catalogs typically list thickness and temper as part of the ordering codes.

Why these details matter to buyers: the Mn content (≈1–1.6%) is the main contributor to corrosion resistance and moderate strength; Mg and Cu are intentionally low so the alloy is non-heat-treatable and behaves predictably under cold work.

Mechanical properties, formability, and joining behavior

We summarize the mechanical envelope that procurement and design teams should use when specifying 3A21 plate:

-

Tensile strength: commonly in the range ~120–160 MPa for typical tempers; tensile numbers vary with temper and thickness.

-

Yield strength: reported values vary, but conditional yield can be near ≥85 MPa in many vendor tables.

-

Elongation: good ductility in annealed states (often ≥20% reported for sheet in softer tempers).

Formability and joining: 3A21 is known for excellent formability in annealed and semi-worked tempers; it is commonly used for automotive body panels and interior structural components where stamping and deep drawing are required. Welding is generally straightforward (resistance, MIG/TIG) but machinability is modest — buyers relying on heavy machining should consider harder machining-friendly alloys.

Product forms, finishes and typical dimensions available

We note how mills and stockists present 3A21 in commerce so specifications match supplier catalogues:

-

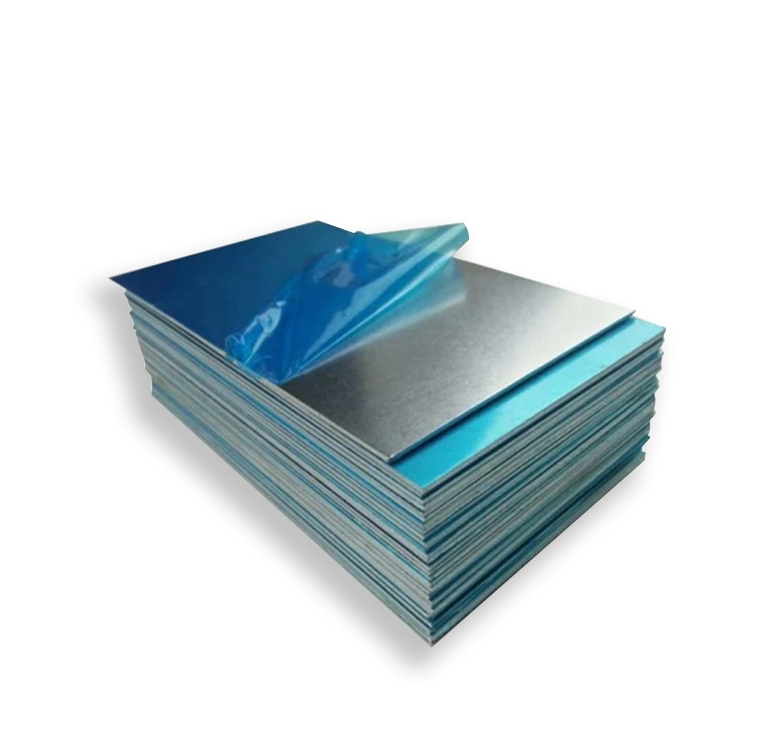

Forms: Coil, sheet, and plate. Plate thickness ranges often from thin gauge (0.1 mm) up to several hundred mm for special orders; common commercial plate widths: 1000–2650 mm; lengths custom.

-

Finishes: mill finish, anodized, embossed, PVC coated, painted, film protected; surface tolerance and surface treatments are selectable at order entry.

-

Typical supply terms: standard mill packs, protective film, banding, and crate packing per export routines.

Where 3A21 performs best

From our experience and survey of supplier datasheets, these are the high-value use cases:

-

Automotive body panels and inner/outer skins (good formability and anti-rust performance are valued).

-

Architectural cladding and façade panels where durability and anti-corrosion matter.

-

Light structural parts, control panels, signage and trim where weldability and surface appearance are required.

-

Appliance panels and decorative applications where cost-effective corrosion resistance is necessary.

How 3A21 compares with close alloys

We compare 3A21 with common alternatives so procurement can make a tradeoff:

-

3A21 vs 3003: 3A21 usually offers similar corrosion resistance and forming ability, but small composition differences can mean slightly different mechanical behaviour and price points. Market listings show 3A21 sometimes priced slightly above 3003 because of its positioning for specific surface and anti-rust claims.

-

3A21 vs 5052/5083: those are Mg-bearing alloys with higher strength and superior marine corrosion resistance; they cost more and are used when strength or marine grade corrosion resistance is required.

-

3A21 vs 1100/1050: the latter are near-pure Al with excellent formability but much lower strength; 3A21 sits between pure-Al families and the higher-strength Mg alloys in terms of properties and cost.

Global price comparison (2025)

We compiled mill and trading quotes, plus regional market indices, and then created a practical table for procurement planning. Prices below are typical market reference points for standard commercial plate thicknesses (not exotic heavy plate) and assume normal order quantities (tonne lot sizes). Prices can change daily with LME spreads, freight, and tariffs.

| Region / Market point | Typical 2025 price (USD / metric ton) | Unit & terms | Notes |

|---|---|---|---|

| China — factory/FOB (commercial lots) | 2,200 – 2,900 / MT | per MT FOB China mills/traders | Many Alibaba/Chinese mill listings for 3A21/3003 family show factory quotes in this band depending on MOQ and thickness. |

| India — domestic primary & spot | ~2,800 – 3,100 / MT | domestic cash / mill price | Indian primary cash points quoted near this band in market reports for 2025. |

| Europe — ex-works / export | 3,500 – 4,800 / MT | ex-works / export prices | European export data for alloy sheet/plate shows higher ex-works price points; value depends on alloy family and grade. |

| United States — distributor / retail & industry | 3,800 – 5,500 / MT | distributor/retail unit prices | U.S. sheet/plate retail and producer indices have been elevated vs. primary LME due to processing, logistics and tariff effects. |

| LME / Primary aluminum benchmark | ~2,400 – 2,800 / MT (primary aluminium reference) | cash / LME | Primary aluminum price movements underpin mill offers; alloy premia & processing add to this base. |

Interpretation and buying signal: China-origin FOB remains the most cost-competitive route for bulk purchases of standard 3A21 plate; however buyers requiring local supply, smaller quantities, or certified inventory will typically see higher landed/retail prices in Europe/US. Our table combines active mill ask ranges with regional indices to give a realistic procurement reference.

What’s driving price in 2025

We continuously monitor these variables because they explain short-term moves and long-term structure:

-

Primary aluminum (LME) base price: movements in the London Metal Exchange and regional cash markets set the raw material floor. When LME rises, mill offers track upward with some lag.

-

Alloy premia & alloying element availability: Mn, Mg and trace elements, plus scrap availability, change mill costs.

-

Energy and processing costs: rolling, heat treatment (if any), and finishing all add margin; energy spikes raise processing premiums.

-

Freight and logistics: container rates, port congestion, and route viability can add several hundred dollars per tonne on short notice.

-

Tariffs, trade policy and quotas: local duties or anti-dumping measures materially change landed cost in certain markets.

-

Inventory cycles and demand spokes: automotive restarts, construction booms, or slowdowns shift demand for sheet/plate families. Recent 2025 data shows upward pressure in specific plate grades due to restocking in some sectors.

Practical purchasing and specification tips

We present concise, actionable suggestions based on working with mills and trading houses:

-

Specify composition and temper clearly in your PO (include an approved mill test certificate (MTC) clause). Use the typical ranges shown in section 3 to set acceptance criteria.

-

Request multiple price breakdowns: show raw material base, processing premium, packing & handling, freight and duties separately. This helps when comparing China FOB vs regional ex-works quotes.

-

MOQ and thickness sensitivity: smaller sizes and single-piece orders attract retail premiums; bundling to full-truck or tonne lots usually secures the lower end of listed price bands.

-

Ask for MTC & test certificates: include tensile/yield, chemical analysis and heat/coil trace. For automotive use ask for surface defect reports and flattening certificates.

-

Negotiate payment and lead times: letters of credit and advance payments will affect pricing; longer lead times might give mills room to adjust price upward with LME moves.

Quality control, testing and certification we recommend

Our standard quality checklist that should appear in every purchase order:

-

Mill Test Certificate (EN 10204 Type 3.1 or equivalent) with full chemical and mechanical values.

-

Certificate of conformity to the specifying standard or customer spec.

-

Non-destructive surface inspection for cosmetic panels (automotive/architectural).

-

Flatness and thickness tolerances agreed in writing (include acceptable mill tolerance table).

-

Welding and forming trials for qualification lots if you plan high-volume production.

-

Accelerated corrosion tests or salt spray if the environment is aggressive.

These items reduce returns, rework and downstream cost overruns.

Handling, storage and corrosion considerations

Storage best practices to protect surface and longevity:

-

Keep packs elevated off ground and under cover to avoid moisture entrapment.

-

If material is protected with film, avoid long-term exposure to UV (film adhesives can harden).

-

For painted/anodized orders, handle with clean gloves and non-abrasive lifting slings.

-

When shipping to coastal destinations, specify extra corrosion protection and rapid inland delivery to reduce exposure to salt air.

Environmental, recycling and lifecycle notes

Aluminum alloys including 3A21 are broadly recyclable with high recovery rates; scrap value and circularity impact long-term cost. Recycling inputs can reduce mill raw material cost but also alter scrap mix, which may slightly change alloy chemistry control — something we monitor when negotiating long contracts.

FAQs

Q1 — What is the typical lead time for 3A21 plate from China mills?

A: For standard stocked thicknesses, typical lead time is 1–3 weeks for small lots; full production/large orders often run 3–6 weeks depending on mill backlog and finishing requirements. Shipping and documentation add additional days.

Q2 — How does temper affect price?

A: Tempers requiring additional cold work or specific finish treatments (e.g., H24 bright drawing or anodizing) often add processing premiums. Plain mill-finish annealed (O) material is usually the lowest price point.

Q3 — Can 3A21 be anodized for decorative facades?

A: Yes — 3A21 accepts anodizing and paint systems after proper surface preparation. Specify anodic coating thickness and pre-treatment in the PO.

Q4 — Is 3A21 suitable for marine environments?

A: While 3A21 has decent corrosion resistance, marine environments call for Mg-bearing alloys like 5052/5083 for long-term immersion or splash zones. If used near coasts, ask for protective finishes and accelerated corrosion testing.

Q5 — How do we convert sheet prices per kg to per MT and compare quotes?

A: Multiply per-kg quotes by 1,000 for MT. Always confirm whether quoted prices are FOB, CIF, EXW or delivered — freight and duty can change final landed cost substantially. Use the breakup format we suggested in section 10 to compare offers fairly.