The 1050 aluminum coil is widely recognized for its high level of purity and exceptional resistance to corrosion. As a key material in various industries, its price fluctuations in 2025 are influenced by multiple factors, including market trends, raw material costs, and geopolitical conditions. This article offers an in-depth analysis of the 1050 aluminum coil price for 2025, drawing insights from industry trends, regional pricing variations, and a comparison of global prices. Additionally, we provide answers to common queries regarding its properties, uses, and factors affecting its cost.

1. Introduction to 1050 Aluminum Coil

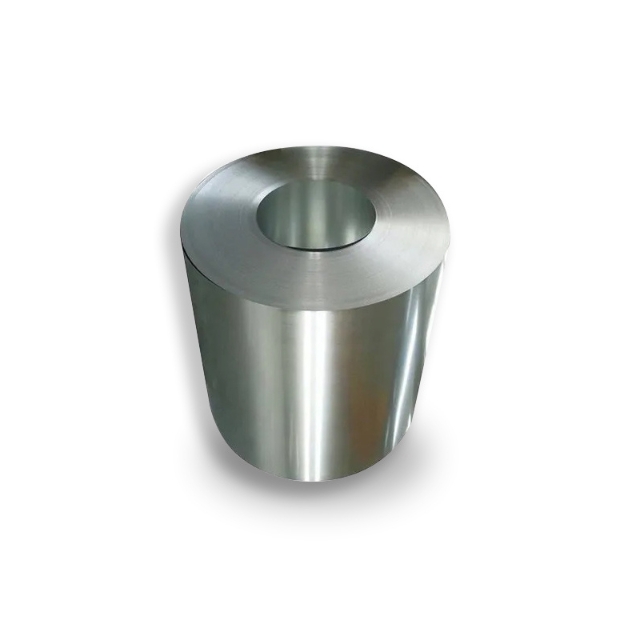

The 1050 aluminum coil is a high-purity, commercially available aluminum alloy, mainly consisting of 99.5% pure aluminum. It is known for its excellent corrosion resistance, formability, and good electrical conductivity. These properties make it ideal for applications in industries such as electrical, chemical, food processing, and construction.

In 2025, the price of 1050 aluminum coil is expected to remain competitive due to the continued demand across various sectors. This price, however, can vary depending on factors like regional supply chains, production costs, and changes in raw material pricing.

2. Factors Affecting the Price of 1050 Aluminum Coil

Several factors contribute to the price of 1050 aluminum coils. These include:

-

Raw Material Costs: The price of aluminum as a base metal is a significant determinant. Aluminum is primarily extracted from bauxite, and fluctuations in bauxite supply or alumina refining costs can affect aluminum prices.

-

Energy Costs: The aluminum production process is energy-intensive. Increases in electricity prices or disruptions in energy supply can lead to higher manufacturing costs.

-

Geopolitical Factors: Political instability or trade policies, especially tariffs or sanctions, can have a direct impact on the price of aluminum coils.

-

Demand from Key Industries: The demand for 1050 aluminum coils in industries like automotive, construction, and packaging plays a role in determining pricing trends.

-

Supply Chain Disruptions: Delays or limitations in the supply of aluminum from major producers like China, Russia, and Canada can create price volatility.

3. Global Price Comparison for 1050 Aluminum Coil in 2025

The price of 1050 aluminum coil varies across different regions due to factors such as local production capabilities, labor costs, and proximity to raw material sources. Below is a table that summarizes the estimated prices of 1050 aluminum coil in various regions for 2025.

| Region | Price Range (per ton) | Notes |

|---|---|---|

| United States | $2,500 - $3,000 | Price increase expected due to higher energy costs. |

| China | $2,200 - $2,500 | Lower costs due to domestic production and favorable tariffs. |

| Europe | $2,600 - $3,100 | Affected by energy surcharges and market conditions. |

| India | $2,300 - $2,700 | Prices relatively stable due to strong domestic supply. |

| Australia | $2,400 - $2,900 | Influenced by export demand and material availability. |

4. Applications of 1050 Aluminum Coil

The 1050 aluminum coil is used extensively in various industries due to its unique properties. Some of the most common applications include:

-

Electrical Industry: Due to its high conductivity, it is used in electrical wiring and electrical components.

-

Food and Beverage Packaging: The alloy’s resistance to corrosion and non-toxic nature makes it ideal for food cans and packaging.

-

Heat Exchangers: Its excellent thermal conductivity is beneficial in heat exchanger systems.

-

Construction and Architectural Uses: It is used in cladding, roofing, and other building materials where durability and low weight are important.

5. 1050 Aluminum Coil's Market Outlook for 2025

The market for 1050 aluminum coils is expected to grow in 2025 due to its diverse range of applications. Increased demand for lightweight materials in the automotive and construction industries, as well as the expansion of renewable energy infrastructure, is likely to drive further consumption of this alloy.

Additionally, advancements in recycling technologies may contribute to more sustainable production, which could stabilize or even lower prices in the long term. However, any significant fluctuations in the global economy or energy markets could influence the cost of 1050 aluminum coils in unpredictable ways.

6. Price Forecast for 1050 Aluminum Coil in 2025

Forecasts indicate that prices will likely continue their upward trend, especially in regions experiencing inflationary pressures. While some regions may see price stabilization, others—particularly those with limited domestic supply or unstable energy sectors—could experience increased costs. Therefore, businesses planning to procure 1050 aluminum coils in 2025 should factor in potential price increases when budgeting.

7. Key Manufacturers and Suppliers of 1050 Aluminum Coil

Several manufacturers and suppliers dominate the 1050 aluminum coil market globally. These include:

-

Alcoa (USA): A major player in the global aluminum industry, Alcoa is expected to continue offering competitive pricing and innovative solutions in the aluminum coil market.

-

China Zhongtai International: Known for its vast production capacity and competitive pricing, particularly in the Chinese domestic market.

-

Novelis (India): A leader in aluminum rolled products, Novelis is a key supplier in both the domestic and international markets.

-

Rio Tinto (Australia): Rio Tinto, with its extensive aluminum production infrastructure, is an important supplier of 1050 aluminum coils globally.

8. Frequently Asked Questions (FAQs)

1. What makes 1050 aluminum coil different from other aluminum alloys?

1050 aluminum is one of the purest grades of aluminum, with a purity level of 99.5% or higher. Unlike other alloys, it is particularly prized for its excellent corrosion resistance and high conductivity, making it ideal for electrical and chemical applications.

2. How does the price of 1050 aluminum coil compare to other aluminum alloys?

1050 aluminum coils are generally less expensive than alloys with higher strength or specific properties, such as 2024 or 7075. This is due to its high purity and simpler manufacturing process, which results in lower production costs.

3. How do energy costs affect the price of 1050 aluminum coil?

Energy costs play a significant role in aluminum production. Since aluminum manufacturing is energy-intensive, rising electricity costs or disruptions in energy supply can increase the overall cost of 1050 aluminum coil production.

4. Can 1050 aluminum coil be recycled?

Yes, 1050 aluminum is highly recyclable, which helps reduce the environmental impact of its production. Recycled aluminum requires less energy to process, making it a more sustainable option for many applications.

5. What are the common thicknesses for 1050 aluminum coil?

1050 aluminum coils are available in a range of thicknesses, typically from 0.2 mm to 10 mm. The choice of thickness depends on the specific application requirements, such as strength, weight, and flexibility.

9. Conclusion

In conclusion, the price of 1050 aluminum coil in 2025 will be shaped by a variety of factors, including raw material costs, regional supply and demand dynamics, and energy prices. While global prices may fluctuate, the alloy's versatility and cost-effectiveness make it a staple in numerous industries. To make informed purchasing decisions, companies and manufacturers need to stay updated on price trends and forecast changes to ensure they remain competitive in the marketplace. By understanding these factors and staying ahead of market movements, businesses can optimize their procurement strategies and minimize costs in the coming year.