The price of 6063 aluminum foil in 2025 is expected to be influenced by several factors, including global demand, production costs, and regional economic conditions. As one of the most commonly used alloys for applications requiring lightweight, durable, and corrosion-resistant materials, 6063 aluminum foil remains a popular choice in industries such as packaging, automotive, and construction. This article provides a comprehensive analysis of the 2025 pricing trends for 6063 aluminum foil, comparing prices across major global markets, highlighting key trends, and addressing the factors that affect pricing. By understanding these elements, businesses and consumers can make more informed decisions about sourcing this essential material.

1. Overview of 6063 Aluminum Foil

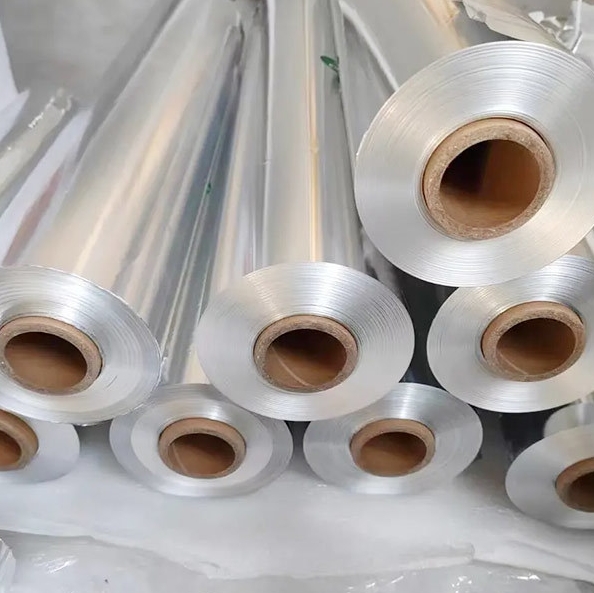

6063 aluminum alloy is primarily known for its high corrosion resistance, lightweight properties, and excellent surface finish. Due to its versatility, 6063 aluminum is widely used in applications that demand precision and aesthetic appeal, such as the manufacturing of windows, doors, and various architectural components. In its foil form, this alloy also serves critical functions in packaging, electrical conductors, and heat exchangers.

The 6063 alloy is characterized by its ability to maintain strength and durability even in corrosive environments. It is commonly used for decorative applications due to its attractive finish and ability to withstand harsh weather conditions, making it a popular material in the construction industry.

2. Global Market Trends for 6063 Aluminum Foil in 2025

The global market for aluminum foil, including 6063 alloy, has been seeing steady growth driven by increasing demand from industries such as packaging, aerospace, and automotive. The global price of aluminum foil is highly sensitive to fluctuations in raw material costs, energy prices, and transportation costs.

In 2025, analysts predict that prices will continue to experience moderate increases, though regional disparities will be evident. In regions with advanced production capabilities such as China, the US, and the EU, prices may remain relatively stable, while emerging markets could see higher price fluctuations due to supply chain challenges and local production constraints.

3. Price Comparison for 6063 Aluminum Foil in Different Regions

| Region | Average Price (USD per Ton) | Price Change Trend (2024-2025) |

|---|---|---|

| North America | 2,500 - 2,800 | Stable with slight increases |

| Europe | 2,600 - 2,900 | Gradual increase due to energy costs |

| Asia | 2,100 - 2,400 | Moderate fluctuation |

| South America | 2,200 - 2,500 | Increased demand leads to slight rise |

| Middle East | 2,300 - 2,600 | Stable, with local variations |

The table above summarizes the expected price ranges for 6063 aluminum foil in different regions of the world. It is important to note that prices can fluctuate based on market demands and raw material availability. For instance, North America and Europe are likely to see incremental price increases, particularly driven by energy costs and manufacturing overheads. On the other hand, Asia and South America might experience larger price variations due to more volatile market conditions.

4. Factors Influencing the Price of 6063 Aluminum Foil

Several factors play a crucial role in determining the price of 6063 aluminum foil. Understanding these factors is essential for businesses to anticipate price fluctuations and secure the best deals. Some of the most significant elements include:

4.1 Raw Material Costs

The primary raw material for aluminum foil is bauxite, which is refined into alumina and then reduced to aluminum metal. The price of bauxite and energy used in the extraction process can have a significant impact on the cost of aluminum foil. In 2025, the global demand for aluminum is projected to rise, which could drive up the cost of raw materials and, consequently, the price of finished products.

4.2 Energy Prices

Energy costs are among the most significant operating expenses in aluminum production. With aluminum smelting being an energy-intensive process, rising energy prices can have a direct impact on the final cost of 6063 aluminum foil. In regions where electricity prices are high, manufacturers may need to pass on these additional costs to consumers.

4.3 Transportation and Logistics

Aluminum is a heavy material, and transportation costs are a significant factor in determining final prices, especially for global markets. Shipping costs, especially as fuel prices rise and supply chain disruptions persist, may contribute to higher prices for aluminum foil products, including 6063 alloy.

4.4 Market Demand

The demand for aluminum foil is largely driven by industries such as packaging, construction, and automotive manufacturing. Any shift in these sectors, such as an increase in building projects or a surge in packaging demand, will likely influence the price of 6063 aluminum foil. The growing demand for lightweight materials in automotive and aerospace industries also pushes the prices upward.

5. Forecast for 6063 Aluminum Foil Pricing in 2025

Looking ahead, we expect 6063 aluminum foil prices to continue their upward trend into 2025. The increasing demand for sustainable and durable materials in construction and packaging is likely to keep the market robust. However, the volatility of global energy prices and raw material costs will remain significant concerns, particularly in the first half of the year.

For businesses, it is recommended to monitor regional price changes, particularly if sourcing materials from areas facing logistical challenges. In addition, locking in prices early or securing long-term contracts may help mitigate some of the risks associated with unpredictable price fluctuations.

6. Key Applications of 6063 Aluminum Foil

6063 aluminum foil is used in a variety of industries due to its versatile properties. Some of the primary applications include:

-

Packaging: It is used extensively for packaging food and pharmaceutical products due to its ability to resist corrosion and preserve the freshness of items.

-

Automotive: The lightweight nature of aluminum foil makes it ideal for use in vehicle manufacturing, particularly for parts that require heat resistance and electrical conductivity.

-

Construction: In construction, 6063 aluminum is used for windows, doors, and other architectural elements due to its corrosion resistance and attractive finish.

-

Aerospace: The aerospace industry also uses aluminum foil in heat exchangers and other components that require lightweight, durable materials.

7. Environmental Considerations in Aluminum Production

As environmental regulations tighten globally, the aluminum production industry is under increasing pressure to adopt sustainable practices. The recycling of aluminum, particularly foil, plays a significant role in reducing the environmental impact of production. Since aluminum is highly recyclable, the growing emphasis on recycling may stabilize prices by increasing the availability of recycled aluminum, which can be used to produce 6063 aluminum foil.

8. Frequently Asked Questions (FAQs)

1. What is the difference between 6063 aluminum foil and other aluminum alloys?

6063 aluminum foil is primarily used in applications that require an attractive finish, high corrosion resistance, and lightweight properties. It differs from other aluminum alloys in terms of strength and resistance to atmospheric corrosion, making it ideal for architectural and decorative purposes.

2. How does the price of 6063 aluminum foil compare to other types of aluminum foil?

6063 aluminum foil generally tends to be more expensive than standard aluminum foil due to its higher quality, strength, and finish. Prices may vary based on regional supply and demand dynamics, with the added value of corrosion resistance justifying the premium cost.

3. Is 6063 aluminum foil recyclable?

Yes, 6063 aluminum foil is highly recyclable. Recycling aluminum reduces the need for raw materials and energy-intensive processes, lowering the environmental impact of aluminum production. Many industries actively promote recycling programs to reduce waste and lower production costs.

4. What industries primarily use 6063 aluminum foil?

6063 aluminum foil is commonly used in packaging, automotive, aerospace, and construction industries. It is especially popular in applications requiring high aesthetic value, corrosion resistance, and durability under various environmental conditions.

5. How can businesses manage fluctuations in 6063 aluminum foil prices?

Businesses can manage price fluctuations by sourcing materials from regions with stable production costs, securing long-term contracts, and exploring alternative supply chains. Additionally, keeping an eye on energy prices and raw material costs will help anticipate significant price changes.

Conclusion

In 2025, the price of 6063 aluminum foil is expected to remain relatively stable, with moderate increases in line with global demand and energy costs. Understanding the factors driving price fluctuations—such as raw material costs, energy prices, and market demand—will help businesses navigate the changing landscape. By staying informed about regional price differences and securing favorable contracts, companies can mitigate risks and continue to access this valuable material for a wide range of applications.