As one of the purest forms of aluminum, 1070 aluminum coil has seen steady demand across various industries, particularly in applications where high corrosion resistance, excellent electrical conductivity, and formability are required. This article provides an in-depth analysis of the current price trends of 1070 aluminum coils, offering valuable insights into pricing across global markets, its applications, and factors influencing pricing in 2025.

1. Introduction to 1070 Aluminum Coil

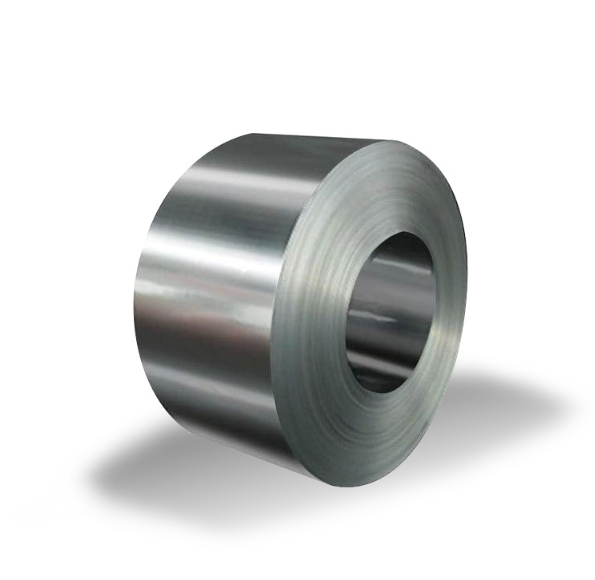

1070 aluminum coil, characterized by its high purity (99.7%), is a versatile metal used extensively in the manufacturing of electrical components, chemical equipment, and for general-purpose use in the form of coils and sheets. Known for its excellent corrosion resistance and good formability, 1070 aluminum finds application in industries such as electronics, automotive, and construction.

Key Properties of 1070 Aluminum Coil

-

High purity (99.7% aluminum)

-

Exceptional corrosion resistance

-

Excellent electrical conductivity

-

High formability and weldability

-

Suitable for various applications, including heat exchangers and decorative products

The price of 1070 aluminum coil can fluctuate based on factors such as production costs, supply-demand dynamics, global trade policies, and the state of the aluminum market.

2. Market Trends and Price Forecast for 1070 Aluminum Coil in 2025

In 2025, global demand for aluminum continues to grow, with 1070 aluminum coils seeing steady price movements. The cost of raw materials, energy, and labor, along with shipping and distribution expenses, plays a significant role in shaping the final pricing for consumers and industries relying on 1070 coils.

Price Trends

-

North America: The price of 1070 aluminum coils in the U.S. has seen a slight increase, largely driven by higher energy costs and the inflationary pressures on labor and raw materials.

-

Europe: Prices in European markets have remained relatively stable due to the availability of local suppliers and a balanced demand across various sectors.

-

Asia: In countries like China, the price has been lower due to abundant production and competitive supply chains, but there has been volatility due to environmental regulations and fluctuating demand from export markets.

3. Factors Affecting the Price of 1070 Aluminum Coil

Several factors contribute to the cost of 1070 aluminum coil, each of which impacts the pricing structure in different ways:

-

Raw Material Costs: The price of bauxite and alumina, key ingredients in aluminum production, directly influences aluminum prices.

-

Energy Prices: Aluminum production is energy-intensive, and fluctuations in electricity and fuel prices can significantly alter production costs.

-

Global Supply Chain: Disruptions caused by logistical challenges, trade tariffs, or raw material shortages can cause temporary price hikes.

-

Manufacturing Capacity: Increases in aluminum production capacity or the introduction of new technologies can help reduce prices.

-

Currency Exchange Rates: Since aluminum is traded globally, fluctuations in the value of the U.S. dollar and other currencies can have an impact on prices.

4. Global Price Comparison for 1070 Aluminum Coil

The price of 1070 aluminum coils can vary across different regions. The following table provides a comparison of prices in major global markets for 2025:

| Region | Price per Ton (USD) | Key Influencing Factors |

|---|---|---|

| North America | $2,300 - $2,500 | Energy costs, labor, and transportation costs |

| Europe | $2,250 - $2,450 | Stable supply chains and demand balance |

| China | $1,900 - $2,100 | Lower production costs, government policies |

| India | $2,000 - $2,200 | Increasing local demand and energy concerns |

| South America | $2,200 - $2,400 | Import taxes and regional transportation issues |

These figures represent average prices and can vary depending on the order size, delivery location, and specific supplier agreements.

5. Applications of 1070 Aluminum Coil

1070 aluminum coil is widely used in industries requiring high-purity aluminum with good electrical conductivity and corrosion resistance. The most common applications include:

-

Electrical Components: Used in cables, bus bars, and power transformers.

-

Chemical Industry: Ideal for heat exchangers, reactor vessels, and piping systems.

-

Decorative Items: Due to its clean, shiny surface, it is used for producing decorative panels and aluminum products.

-

Automotive: Used for lightweight applications in the automotive sector to enhance fuel efficiency.

6. Why Choose 1070 Aluminum Coil Over Other Grades?

1070 aluminum coil stands out among other grades due to its high purity and exceptional properties. Compared to alloys such as 1050 or 1100 aluminum, 1070 aluminum offers:

-

Better Electrical Conductivity: The high purity ensures minimal resistance, making it ideal for electrical applications.

-

Enhanced Corrosion Resistance: The absence of other metals in significant quantities allows it to perform well in aggressive environments.

-

Superior Formability: Easy to fabricate and shape, making it versatile for various industrial uses.

7. How to Choose the Right Supplier for 1070 Aluminum Coil

When sourcing 1070 aluminum coils, it's important to select a reliable supplier that meets specific industry standards. Consider the following criteria:

-

Certifications: Ensure that the supplier holds relevant certifications such as ISO, ASTM, or other regional standards.

-

Production Capacity: A supplier with large-scale production capabilities can ensure timely deliveries and cost-effective pricing.

-

Reputation: Look for suppliers with a strong market presence and positive feedback from previous customers.

-

Customization Options: Many industries require specific dimensions or coatings for aluminum coils; ensure the supplier can accommodate these needs.

8. 5 Frequently Asked Questions (FAQs)

1. What is the difference between 1070 aluminum coil and other aluminum grades?

1070 aluminum has the highest purity among the commercially available grades, which gives it excellent electrical conductivity and corrosion resistance compared to grades like 1050 and 1100.

2. What industries use 1070 aluminum coil?

1070 aluminum coil is widely used in the electrical, automotive, and chemical industries for applications like cables, heat exchangers, and reactor vessels.

3. How can I get a quote for 1070 aluminum coil?

To get an accurate quote, it's important to provide the supplier with your required dimensions, quantity, and delivery location.

4. Why are prices for 1070 aluminum coil different across regions?

Regional price variations can be attributed to factors like local production costs, supply chain conditions, and international tariffs.

5. Is 1070 aluminum coil recyclable?

Yes, like most aluminum products, 1070 aluminum coil is highly recyclable, which makes it an environmentally friendly material option.

9. Conclusion

The price of 1070 aluminum coil in 2025 reflects the complex interplay of market trends, raw material costs, and regional supply and demand. While global prices may fluctuate due to geopolitical factors or energy costs, 1070 aluminum's unique properties ensure its continued demand across several key industries. By understanding the factors that influence pricing and choosing the right supplier, industries can better navigate the purchasing process for aluminum coils.